Paver

A technology of paver and heating pipe, applied in the direction of roads, road repair, roads, etc., can solve the problems of heavy and laborious screed floor, affecting the quality of road construction, and achieve the effect of ensuring construction quality and saving construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

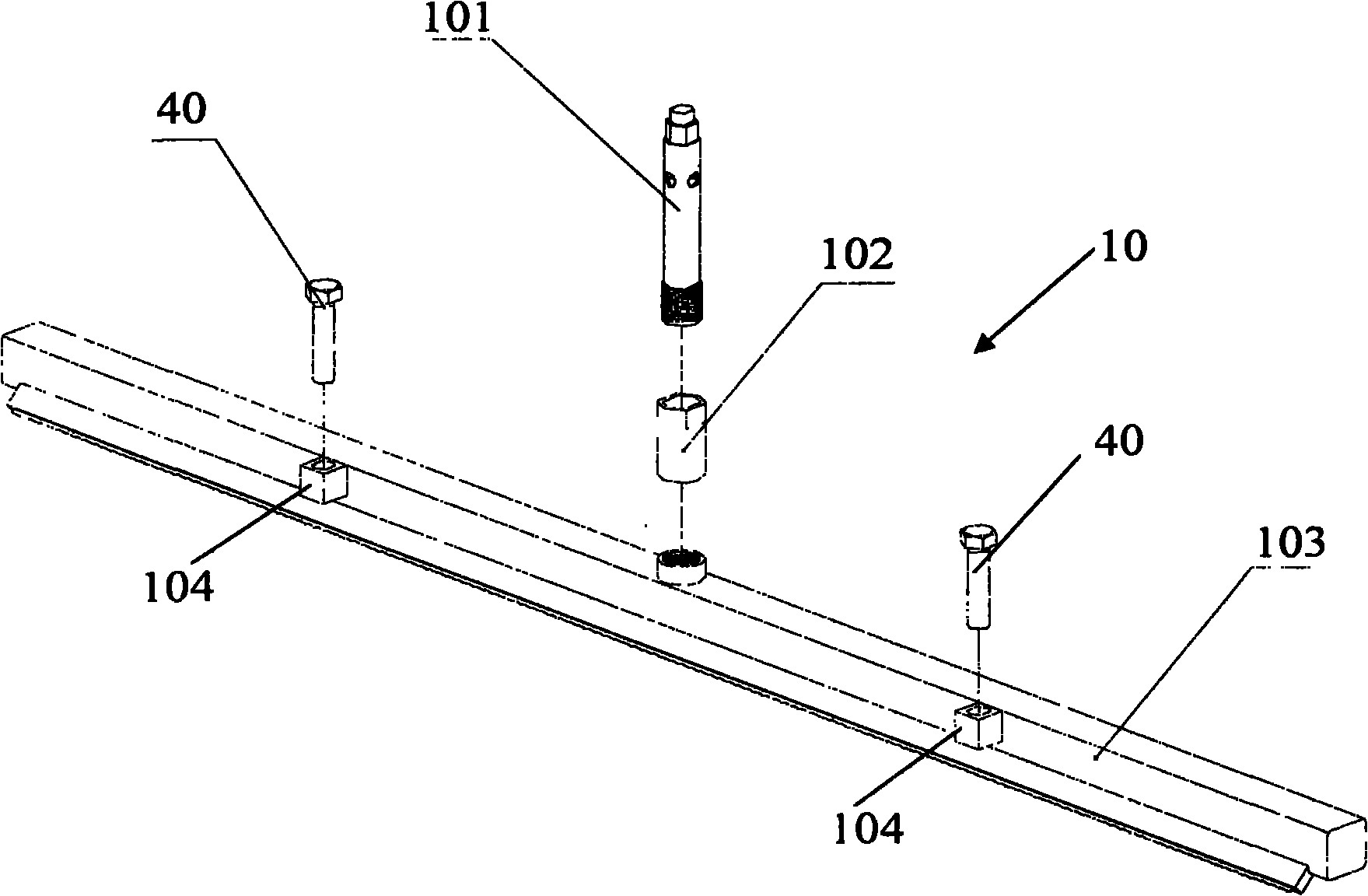

[0020] figure 1 , figure 2 and image 3 A paver according to the present invention is schematically shown, as shown in the figure, including: a heating device 10 and a screed box 20; the heating device 10 includes: a heating pipe 103 and a ventilation pipe 101; the screed box 20 It includes: two side plates 201, 202, a cover plate 203 and a screed base plate 204 arranged between the two side plates, the two side plates, the cover plate and the screed base plate are fixedly connected, and the space formed is a screed box body combustion chamber. The heating pipe 103 is arranged inside the screed box 20, and the air hole end of the air pipe 101 is located outside the screed box 20; the heating device 10 is detachably connected to the screed box 20; the air pipe 101 is detachably connected to the heating On the pipe 103; the screed box 20 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com