Magnetic iron oxide-dendritic polyamide core-shell nano complex and preparation thereof

A magnetic iron oxide, core-shell nanotechnology, which is applied in the field of magnetic iron oxide-dendritic polyamide core-shell nanocomposites and its preparation, can solve the problem of unsatisfactory effects from target genes to target cells, and promote collapse , improve stability, improve the effect of expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Add 0.5M Fe 2+ and Fe 3+ solution, mixed in a molar ratio of 1:2, with a total volume of 30ml. At 75°C, under nitrogen protection, add dropwise to NH 3 -NH 4In the Cl buffer solution (pH=10, total volume 15ml), 10ml of concentrated ammonia water was added at the same time, and the reaction was terminated after 90min of magnetic stirring. After magnetic separation and distilled water washing, the product was redispersed in 1.0M sodium citrate solution, and mechanically stirred at 60°C for 12h. After the product is washed by magnetic separation, it is made into a 30 mg / ml water-based magnetic fluid.

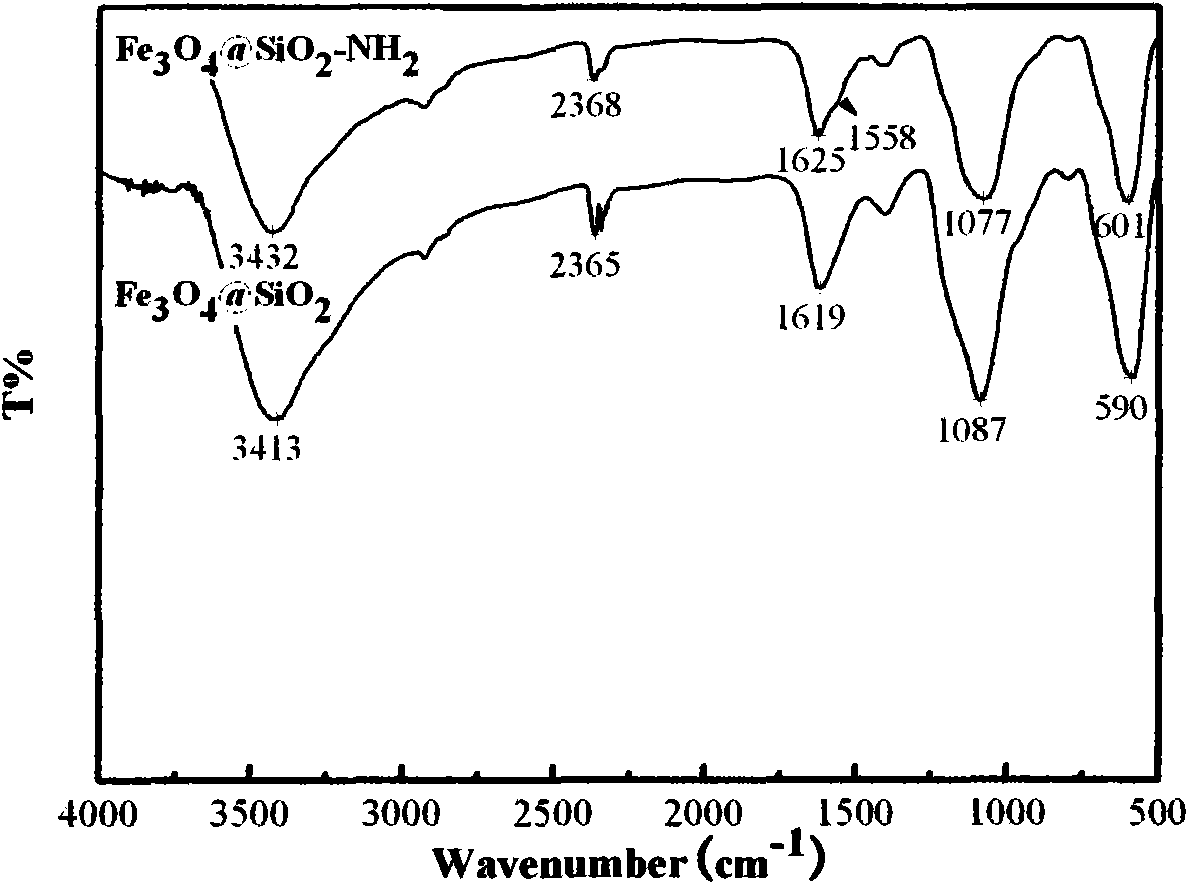

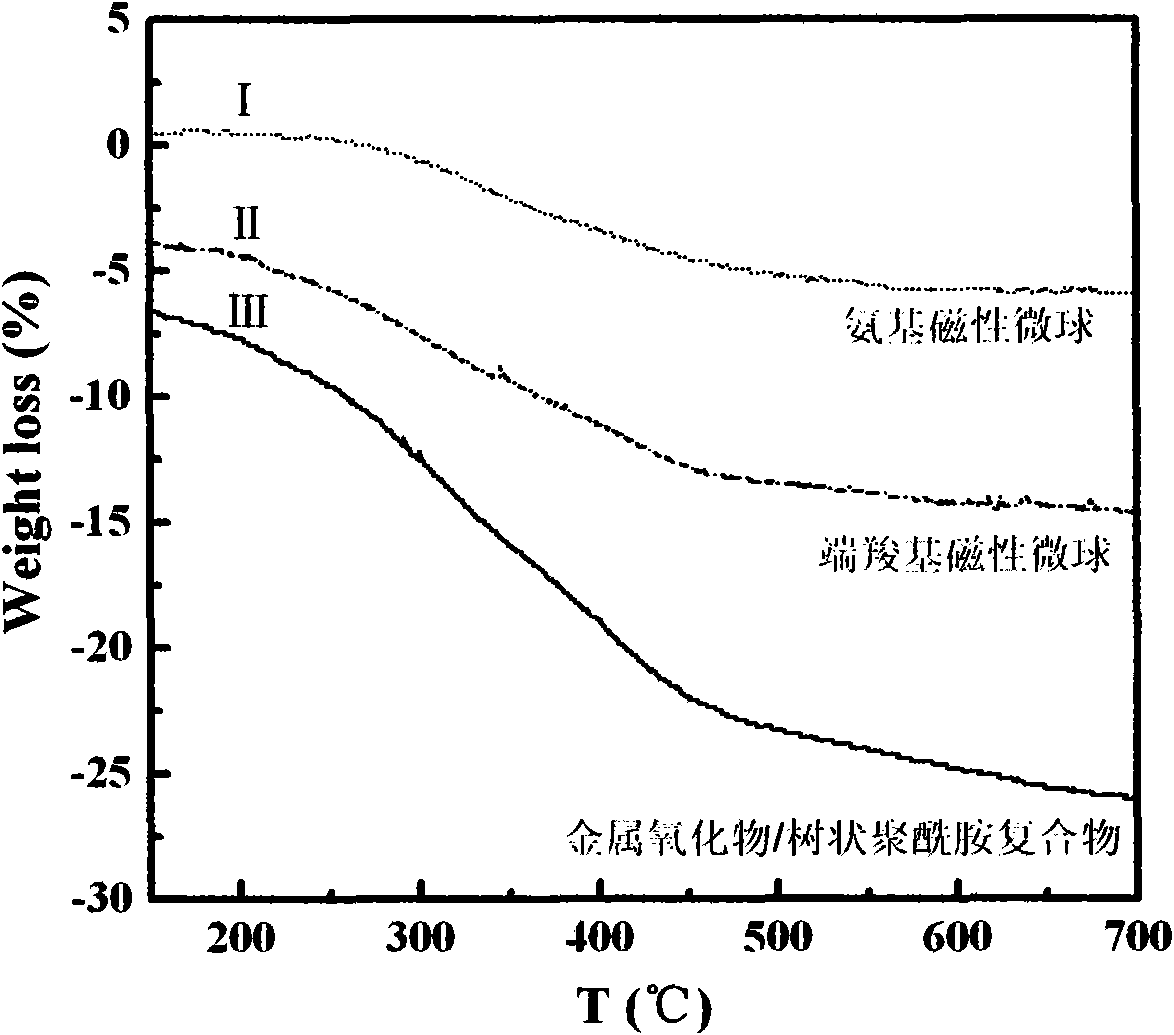

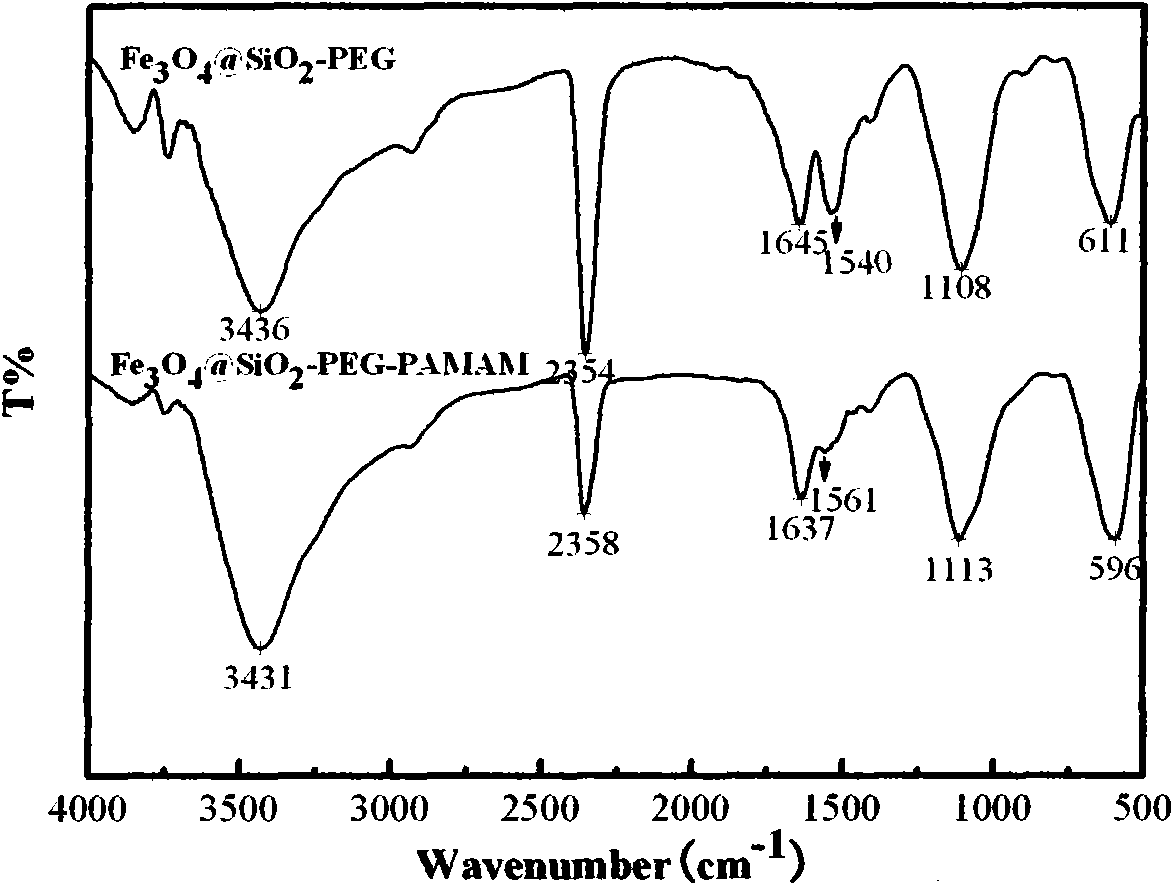

[0035] 2. Secondary surface modification of magnetic fluid with silane coupling agent. Disperse 2ml of magnetic fluid in an alcohol-water mixture with a volume ratio of 4:1, then add 5ml of ammonia water and 0.01ml of tetraethylorthosilicate, and stir mechanically at 30°C for 12h. The product was magnetically separated, washed with anhydrous ethanol, acetone and anh...

Embodiment 2

[0047] 1. Add 0.5M Fe 2+ and Fe 3+ solution, mixed at a molar ratio of 1:1, with a total volume of 30ml. At 55°C, under nitrogen protection, add dropwise to NH 3 -NH 4 In the Cl buffer solution (pH=9, total volume 15ml), 10ml of concentrated ammonia water was added at the same time, and the reaction was terminated after magnetic stirring for 60min. After magnetic separation and distilled water washing, the product was redispersed in 1.0M sodium citrate solution, and mechanically stirred at 60°C for 12h. After the product is washed by magnetic separation, it is made into a 30 mg / ml water-based magnetic fluid.

[0048] 2. Secondary surface modification of magnetic fluid with silane coupling agent. Disperse 2ml of magnetic fluid in an alcohol-water mixture with a volume ratio of 4:1, then add 5ml of ammonia water and 0.01ml of tetraethylorthosilicate, and stir mechanically at 30°C for 10h. After the product was magnetically separated, washed with absolute ethanol, acetone a...

Embodiment 3

[0053] 1. Add 0.5M Fe 2+ and Fe 3+ solution, mixed at a molar ratio of 1:1, with a total volume of 30ml. At 60°C, under the protection of nitrogen, add dropwise to NH 3 -NH 4 In the Cl buffer solution (pH = 11, total volume 15 ml), 10 ml of concentrated ammonia water was added at the same time, and the reaction was terminated after magnetic stirring for 60 min. After magnetic separation and distilled water washing, the product was redispersed in 1.0M sodium citrate solution, and mechanically stirred at 60°C for 12h. After the product is washed by magnetic separation, it is made into a 30 mg / ml water-based magnetic fluid.

[0054] 2. Secondary surface modification of magnetic fluid with silane coupling agent. Disperse 2ml of magnetic fluid in an alcohol-water mixture with a volume ratio of 4:1, then add 5ml of ammonia water and 0.01ml of tetraethylorthosilicate, and stir mechanically at 30°C for 12h. After the product was magnetically separated, washed with absolute ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com