Structural modification type cameclia oleifera saponin and preparation method and application thereof

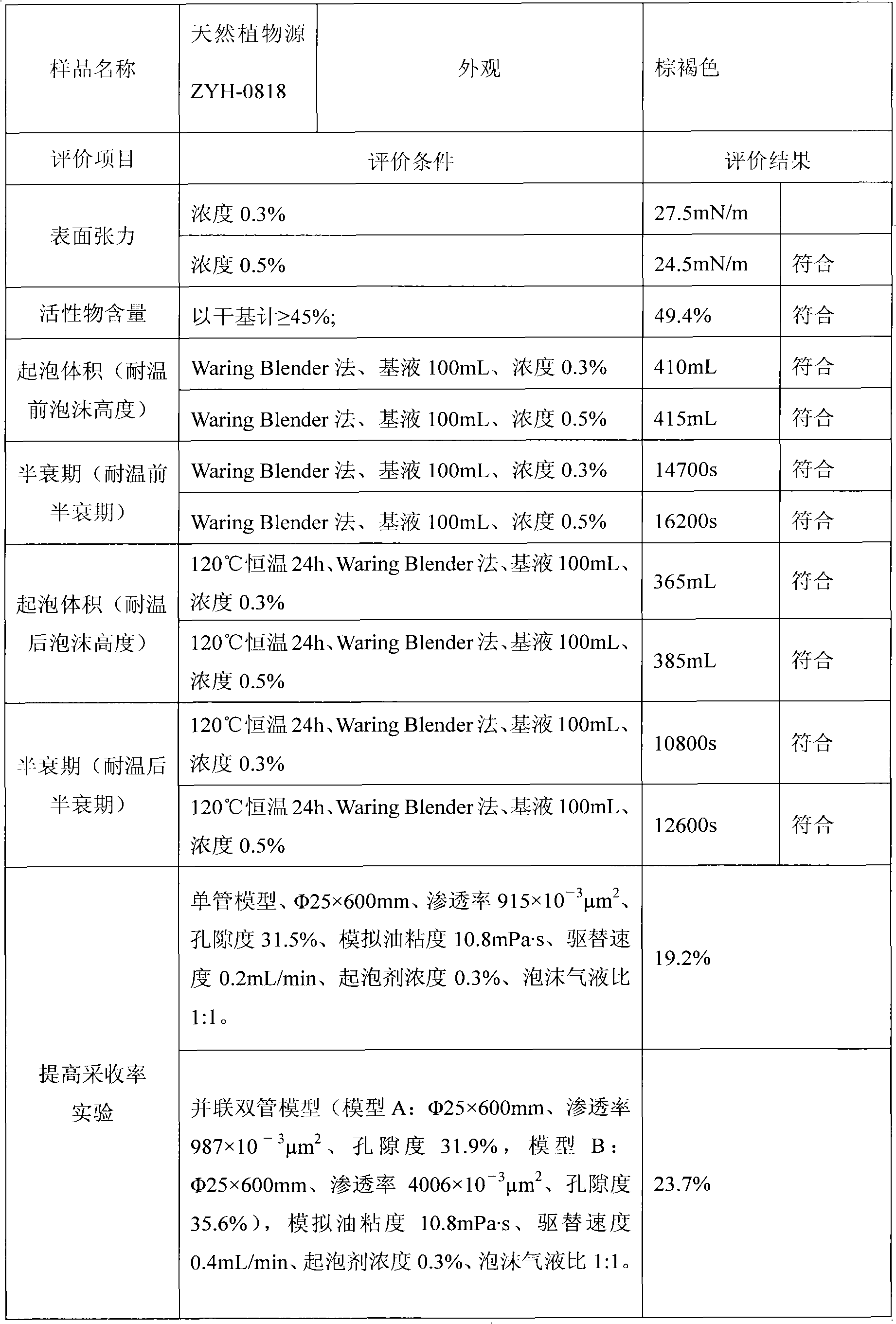

A camellia saponin and complete reaction technology, applied in chemical instruments and methods, steroids, drilling compositions, etc., can solve the problems of temperature resistance, salt resistance, acid resistance, poor stability, high price, groundwater, geological environment, etc. Pollution and other problems, to achieve the effect of high foaming ratio, long foam stabilization time, and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

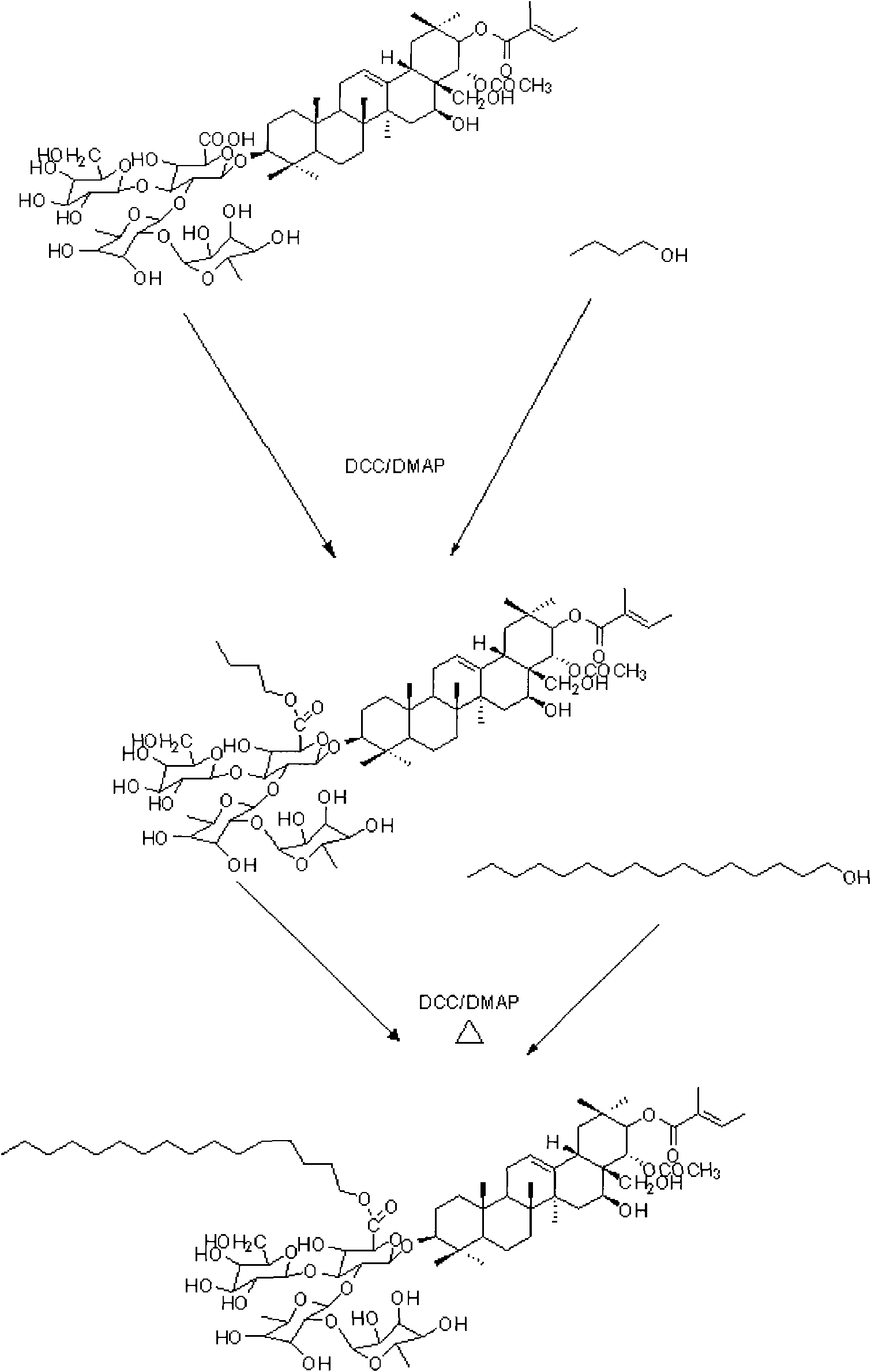

Method used

Image

Examples

Embodiment 1

[0043] (a) In 1000L reaction kettle A, add substrate raw materials-200 kg of self-made camellia saponin powder, 300 kg of n-butanol, heat to 60-70°C, stir for 60 minutes under normal pressure, so that camellia oleifera saponin is fully dissolved, Cool to 50°C and filter, and pump the filtrate into another 1000L reactor B.

[0044] (b) Add 150 kilograms of N in reactor B, N '-dicyclohexylcarbodiimide (DCC), 10 kilograms of 4-dimethylaminopyridine (DMAP), stir at room temperature and carry out esterification reaction, track Monitor the reaction (trace with thin-layer chromatography, take the disappearance of camellia saponin point as the reaction end point, the same below), and react for 5 hours.

[0045] (c) Add 40 kg of cetyl alcohol to the reaction kettle, and stir at room temperature for 3 hours. Heat to 80-90°C, depressurize to 0.01MPa, stir to carry out transesterification reaction, track and monitor the reaction (trace with thin-layer chromatography, take the disappearan...

Embodiment 2

[0048] (a) In the 1000L reaction kettle A, add matrix raw materials-200 kg of self-made camellia saponin powder and 200 kg of n-butanol, heat to 50-70°C, stir for 60 minutes under normal pressure to fully dissolve camellia oleifera saponin, and cool to Filter at 20°C, and pump the filtrate into another 1000L reactor B.

[0049] (b) 100 kg of N,N'-dicyclohexylcarbodiimide (DCC) and 2 kg of 4-dimethylaminopyridine (DMAP) were added to reaction kettle B, and the reaction was stirred at room temperature for 4 hours.

[0050] (c) condition is the same as (c) in embodiment 1.

[0051] (d) The conditions are the same as (d) in Example 1, and finally 270 kg of structure-modified Camellia oleifera saponin is obtained, wherein the solid content is 58%.

Embodiment 3

[0053] (a) In the 1000L reaction kettle A, add matrix raw materials-200 kg of self-made camellia saponin powder and 400 kg of n-butanol, heat to 70-90°C, stir for 60 minutes under normal pressure to fully dissolve camellia oleifera saponin, and cool to Filter at 30°C, and pump the filtrate into another 1000L reactor B.

[0054] (b) 180 kg of N,N'-dicyclohexylcarbodiimide (DCC) and 16 kg of 4-dimethylaminopyridine (DMAP) were added to reactor B, and the reaction was stirred at room temperature for 8 hours.

[0055] (c) condition is the same as (c) in embodiment 2.

[0056] (d) The conditions are the same as (d) in Example 2, and finally 290 kg of structure-modified Camellia oleifera saponin is obtained, with a solid content of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com