Building mortar additive and production method thereof

An admixture and mortar technology, which is applied in the field of construction mortar admixture and its production, can solve the problems of affecting the strength of mortar, cumbersome operation, and brittle mortar, so as to improve the bonding force and mortar strength, stable physical and chemical properties, and overall The effect of strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A mortar admixture, its raw material composition and parts by weight are as follows:

[0059] Sodium Lauryl Sulfate 6 parts

[0060] Triethanolamine 1.6 parts

[0061] Bishydroxyethyl laurylamide 4 parts

[0062] Nonylphenol polyvinyl ether 2 parts

[0063] 0.4 parts of tributyl phosphate

[0064] 2 parts wood calcium

[0065] 3 parts ethylene glycol

[0066] 50 parts meerschaum

[0067] Calcium carbonate 50 parts

[0068] The preparation method is:

[0069] Add sepiolite and calcium carbonate to the mixing equipment first, then add sodium lauryl sulfate, triethanolamine, bishydroxyethyl dodecylamide, tributyl phosphate, nonylphenol polyvinyl ether, wood calcium , Ethylene glycol was added, sealed and stirred, and the stirring time was about 13-15 minutes, and mixed into a powdery object with a fineness of 0.9MM sieve residue < 15%, which was a finished product.

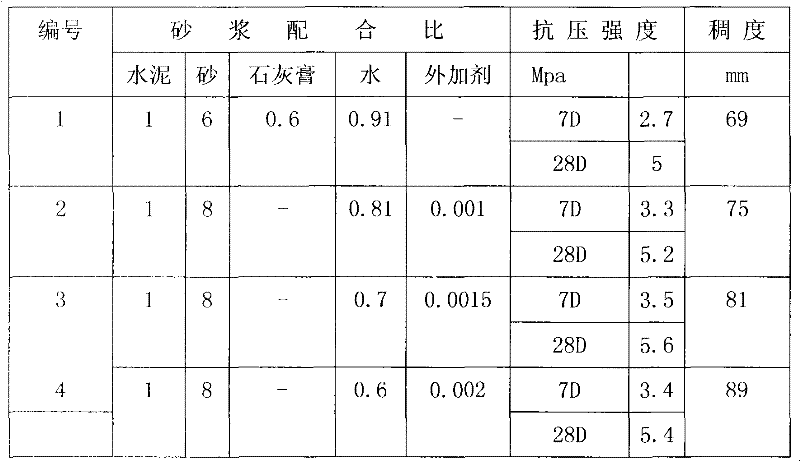

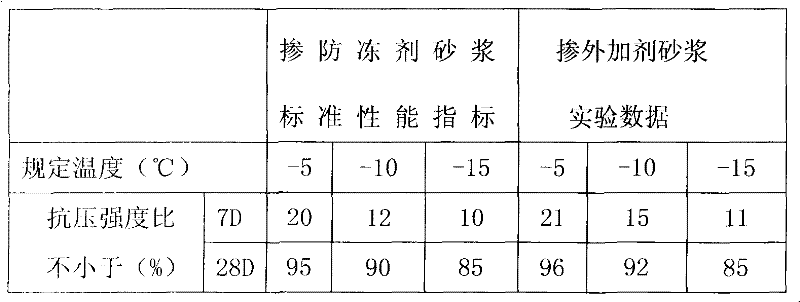

[0070] Test effect comparison of the present invention:

[0071] One, add the mortar of the prese...

Embodiment 2

[0076] A mortar admixture, its raw material composition and parts by weight are as follows:

[0077] 7 parts sodium lauryl sulfate

[0078] 2 parts triethanolamine

[0079] Bishydroxyethyl dodecylamide 2.4 parts

[0080] 2.5 parts of nonylphenol polyvinyl ether

[0081] 0.3 parts of tributyl phosphate

[0082] 1.5 parts of wood calcium

[0083] 4.5 parts of ethylene glycol

[0084] 55 parts meerschaum

[0085] Calcium carbonate 45 parts

[0086] The preparation method is:

[0087] Add sepiolite and calcium carbonate to the mixing equipment first, then add sodium lauryl sulfate, triethanolamine, bishydroxyethyl dodecylamide, tributyl phosphate, nonylphenol polyvinyl ether, wood calcium , Ethylene glycol was added, sealed and stirred, and the stirring time was about 13-15 minutes, and mixed into a powdery object with a fineness of 0.9MM sieve residue < 15%, which was a finished product.

[0088] Test effect comparison of the present invention:

[0089] One, add the mor...

Embodiment 3

[0094] A mortar admixture, its raw material composition and parts by weight are as follows:

[0095] Sodium Lauryl Sulfate 8 parts

[0096] 2.5 parts of triethanolamine

[0097] Bishydroxyethyl laurylamide 2 parts

[0098] Nonylphenol polyvinyl ether 3 parts

[0099] Tributyl phosphate 0.2 parts

[0100] Wood calcium 1.2 parts

[0101] 5 parts of ethylene glycol

[0102] 60 parts meerschaum

[0103] 40 parts calcium carbonate

[0104] The preparation method is:

[0105] Add sepiolite and calcium carbonate to the mixing equipment first, then add sodium lauryl sulfate, triethanolamine, bishydroxyethyl dodecylamide, tributyl phosphate, nonylphenol polyvinyl ether, wood calcium , Ethylene glycol was added, sealed and stirred, and the stirring time was about 13-15 minutes, and mixed into a powdery object with a fineness of 0.9MM sieve residue < 15%, which was a finished product.

[0106] Test effect comparison of the present invention:

[0107] One, add the mortar of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com