Radial water-treatment biological filler and production method thereof

A technology of biological filler and production method, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. It can solve the problems of easy film formation of fillers, etc., and achieve extremely easy film formation and good effect , The effect of reducing the amount of sludge generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with embodiment:

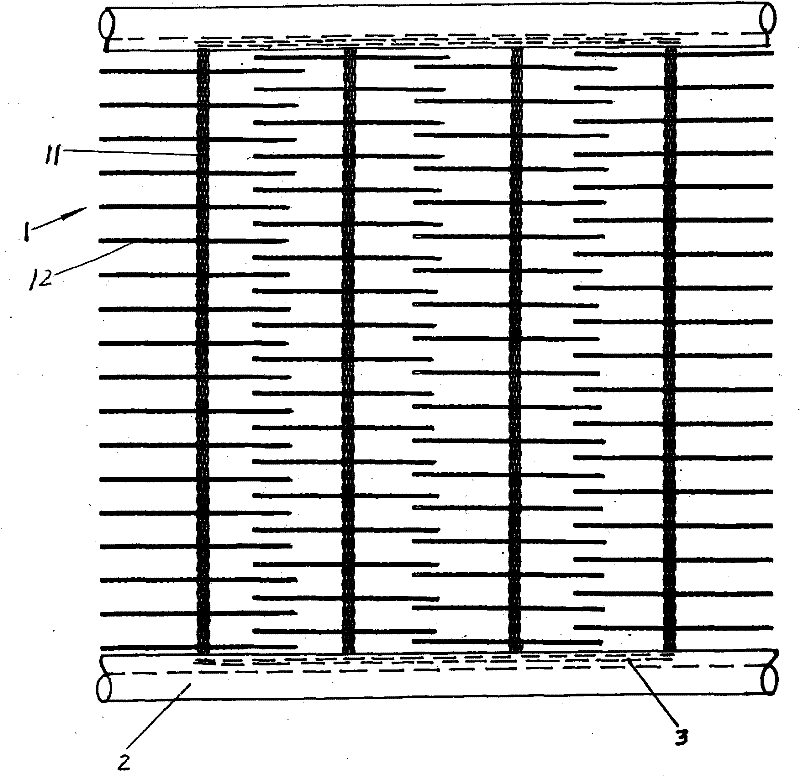

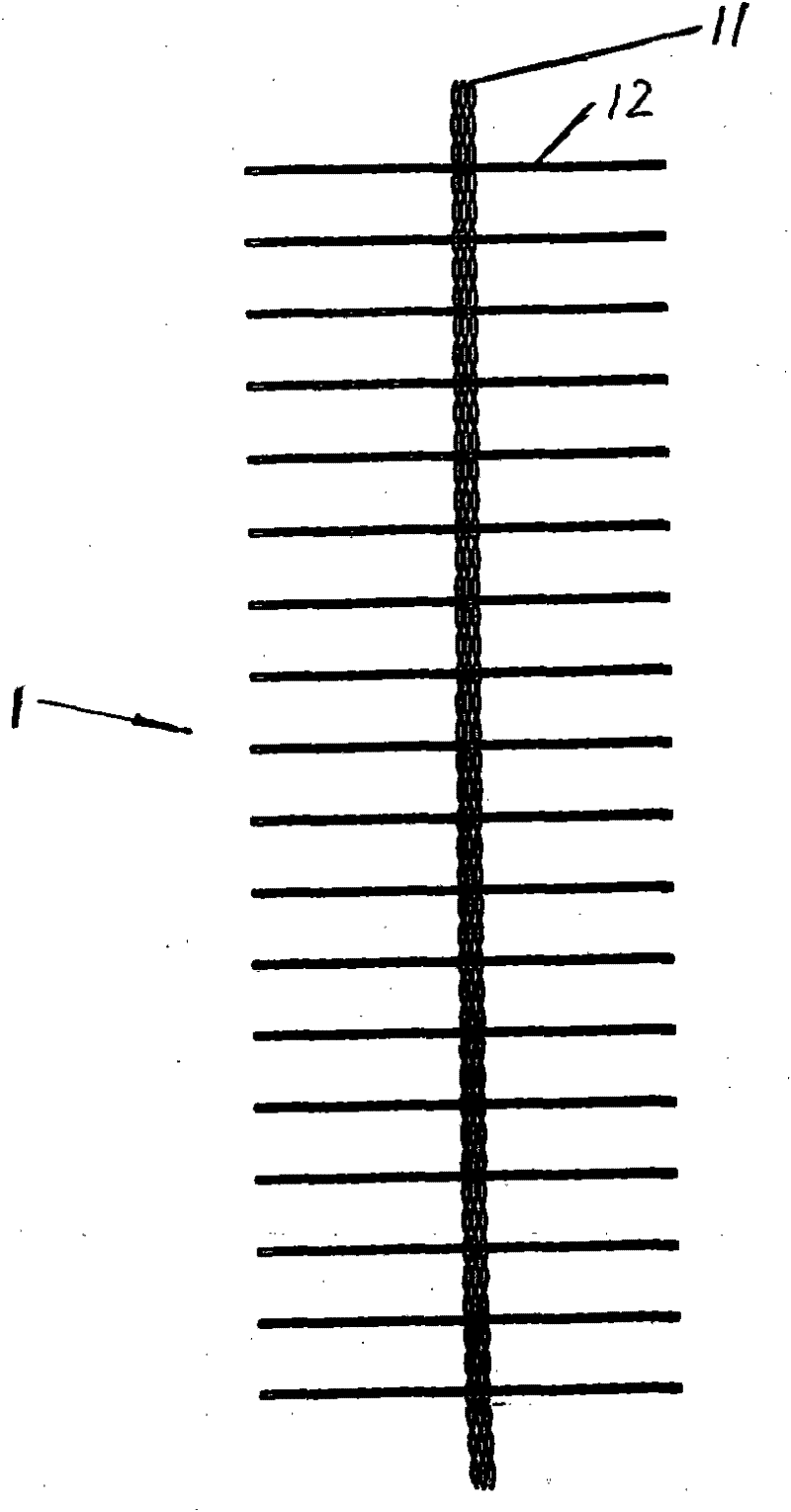

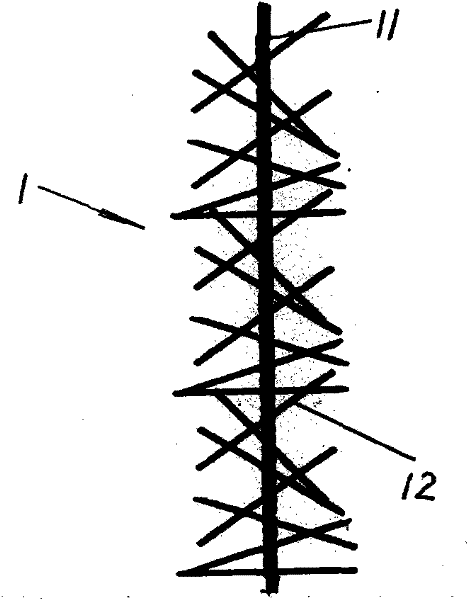

[0017] Such as figure 1 , figure 2 As shown, the first embodiment of the present invention has two fixed sleeves 2, several wire bodies 1, and fixed braided wires 3, and the two ends of each wire body 1 are respectively fixed on the corresponding positions by fixed braided wires 3. On the two fixed sleeves 2 of tube shape. Each of the thread body 1 has a vertical thread body (vertical thread) 11 woven by several hydrophobic chemical synthetic fiber yarns (or chemical fiber silk yarns). Some horizontal thread bodies (horizontal threads) 12 made of hydrophilic chemical synthetic fiber silk yarn, each horizontal thread body 12 in each thread body 1 is all woven with vertical thread body 11 at its middle position Together, the transverse body presents a radial linear structure. There can be one or two or more than two lines mentioned above, and generally multiple lines are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com