Preparation method and application of amphoteric chelate sorbent containing agricultural straw

A technology for chelating adsorbent and straw, which is applied in the field of preparation and application of amphoteric chelating adsorbent for agricultural straw, can solve the problems of secondary pollution, single functional group, low metal ion adsorption capacity, etc., and achieves a simple and good production process. The effect of water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

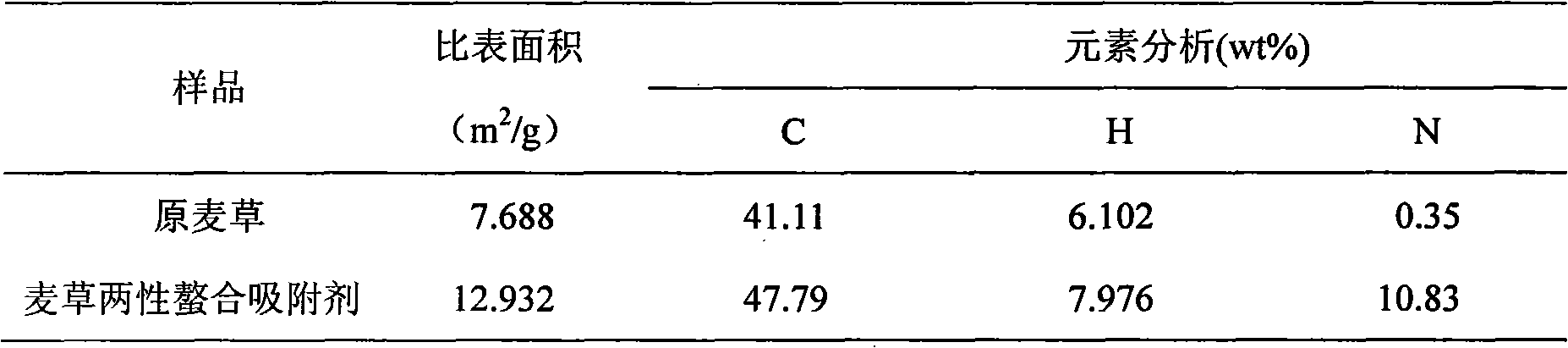

Image

Examples

Embodiment 1

[0024] (1) Take wheat straw with a particle size of 500 μm, mix it with 5 milliliters of epichlorohydrin per gram of agricultural straw, and stir in a three-necked bottle. During stirring, add 5 milliliters per gram of agricultural straw, add N,N-dimethylformamide, stirred and reacted at 100°C for 60min;

[0025] (2) Add cross-linking agent ethylenediamine into the three-necked bottle, mix each gram of agricultural straw with 2 ml of cross-linking agent, continue to stir and react for 60 minutes, and the reaction temperature is 100°C;

[0026] (3) Add a solution of grafting reactant triethylamine with a mass percentage concentration of 99%, mix each gram of agricultural straw with 5 ml of grafting reactant, and stir and react at 100° C. for 180 min;

[0027] (4) the solid product that step (3) obtains is washed successively with 0.1mol L -1 NaOH solution, 0.1mol L -1 HCl solution, volume percent concentration of 50% C 2 h 5 Wash with OH and deionized water, dry in vacuum a...

Embodiment 2

[0031] Wheat straw and epichlorohydrin are stirred and reacted, and cross-linking agent ethylenediamine is added, then triethylamine solution is added, and the batching ratio between them is wheat straw: epichlorohydrin: ethylenediamine: triethylamine solution=1g : 2ml: 1ml: 5ml, prepared wheat straw anion adsorbent A; then A is reacted with isopropanol and water stirring, and NaOH is added, then monochloroacetic acid is added, and the batching ratio between them is A: (isopropanol+ Water): NaOH: monochloroacetic acid=1g: (13.45ml+0.67ml): 0.75ml: 0.51g to obtain the wheat straw amphoteric chelate adsorbent.

[0032] The operation steps are the same as in Example 1, except that the added epichlorohydrin is 2ml and ethylenediamine is 1ml.

Embodiment 3

[0034] Wheat straw and epichlorohydrin are stirred and reacted, and cross-linking agent ethylenediamine is added, then triethylamine solution is added, and the batching ratio between them is wheat straw: epichlorohydrin: ethylenediamine: triethylamine solution=1g : 10ml: 10ml: 5ml, prepared wheat straw anion adsorbent A; then A is reacted with isopropanol and water stirring, and NaOH is added, then monochloroacetic acid is added, and the batching ratio between them is A: (isopropanol+ Water): NaOH: monochloroacetic acid=1g: (13.45ml+0.67ml): 0.5ml: 0.51g to obtain the wheat straw amphoteric chelate adsorbent.

[0035] The operation steps are the same as in Example 1, except that the added epichlorohydrin is 10ml, ethylenediamine is 10ml, and the amount of NaOH is 0.5ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com