Method for manufacturing soya-bean milk and soymilk grinder applying same

A production method and technology of a soymilk machine, which are applied to dairy products, milk substitutes, applications, etc., can solve the problems of reducing the taste of soymilk, insufficient grinding fineness, affecting the taste, etc., and achieve humanized control, increase concentration, and delicate taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

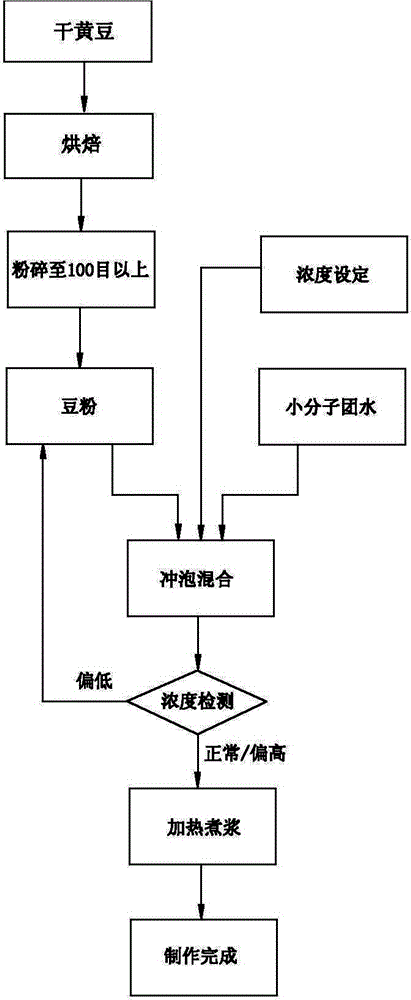

Embodiment approach 1

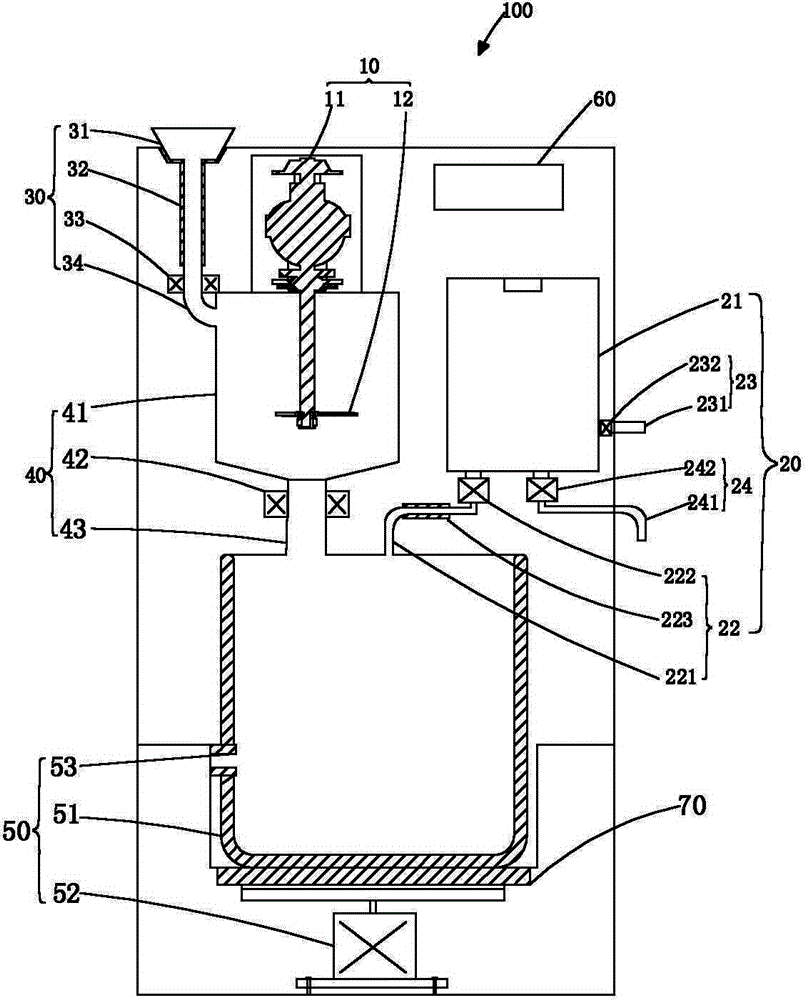

[0026] see figure 1 Shown is a soymilk maker 100 suitable for the soymilk production method of the present invention, the soymilk maker 100 includes a crushing device 10, a water treatment device 20, a feeding device 30, a crushing chamber 40, a brewing device 50, a control circuit board 60 and a heating device 70. The crushing device 10 and the feeding device 30 are arranged on the crushing chamber 40, the crushing chamber 40 and the water treatment device 20 communicate with the brewing device 50 respectively, and the bottom of the brewing device 50 is provided with a heating device 70 for heating the slurry.

[0027] The crushing device 10 includes a motor 11 and a cutter 12 , and the cutter 12 is arranged at one end of the motor shaft of the motor 11 .

[0028] The water treatment device 20 includes a water storage chamber 21 , a water outlet channel 22 , a water inlet channel 23 and a sewage channel 24 . The water storage chamber 21 communicates with the water outlet cha...

Embodiment approach 2

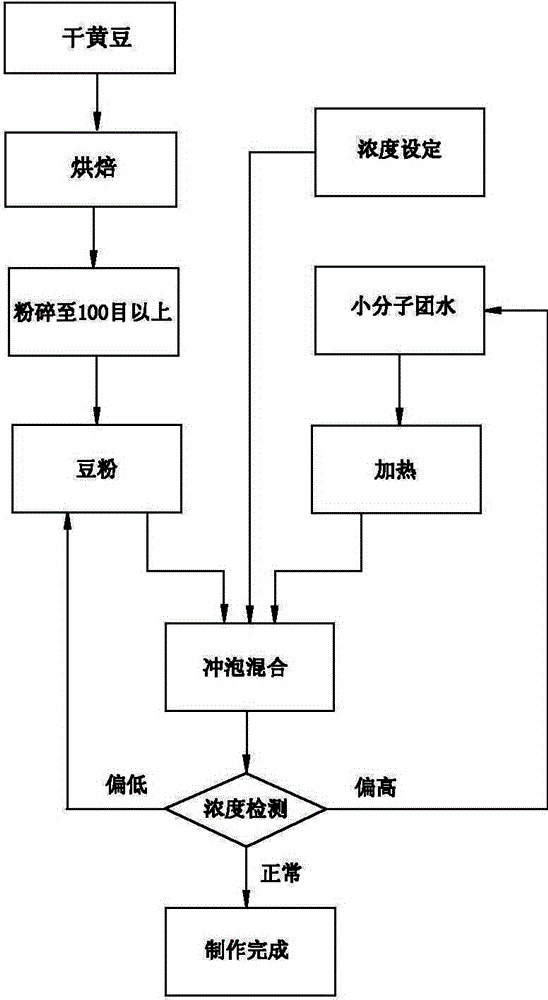

[0044] see image 3 Compared with the first preferred embodiment, the second preferred embodiment of the soymilk production method of the present invention differs in that: the small molecule water treated by the water treatment device 20 in step (2) may also include a heating process , the control circuit board 60 activates the heater 223 to heat-treat the small-molecular water flowing through the water inlet pipe 231, the temperature of the small-molecular water is controlled at 75° C. to 100° C. When the temperature of the temperature is lower than 75°C, it is unfavorable to precipitate the protein in the soybean flour during brewing, and the taste of the soybean milk after brewing is poor. If the temperature of the small molecular water is higher than 100°C, the water will vaporize, and the small molecular water will The reduction of the activity of the heat will affect the brewing effect. In this embodiment, the effect is best when the heating temperature is controlled at...

Embodiment approach 3

[0049] see Figure 4 The third preferred embodiment of the soymilk production method of the present invention is different from the first preferred embodiment in that in step (1), the beans in the feeding device 30 directly enter the crushing chamber 40 for crushing Cavity 41 pulverizes, and this bean is the uncooked bean of ripening treatment. In step (2), the small molecular cluster water treated by the water treatment device 20 also includes a heating process, and the control circuit board 60 starts the heater 223 to heat the small molecular cluster water flowing through the water inlet pipe 231 , the temperature of the small molecular mass water after the heat treatment is controlled at 85°C to 100°C. Since raw soybean powder is used for brewing, if the temperature of the small molecular mass water is lower than 85°C, the temperature of the slurry after brewing and mixing It will be further reduced, which is not conducive to removing the beany smell in raw soybean powder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com