Color filter substrate, liquid crystal display panel, liquid crystal display device, and method for manufacturing color filter substrate

A liquid crystal display panel, color filter technology, applied in the direction of optical filters, identification devices, optics, etc., can solve the problems of light leakage, color reproducibility reduction, contrast reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

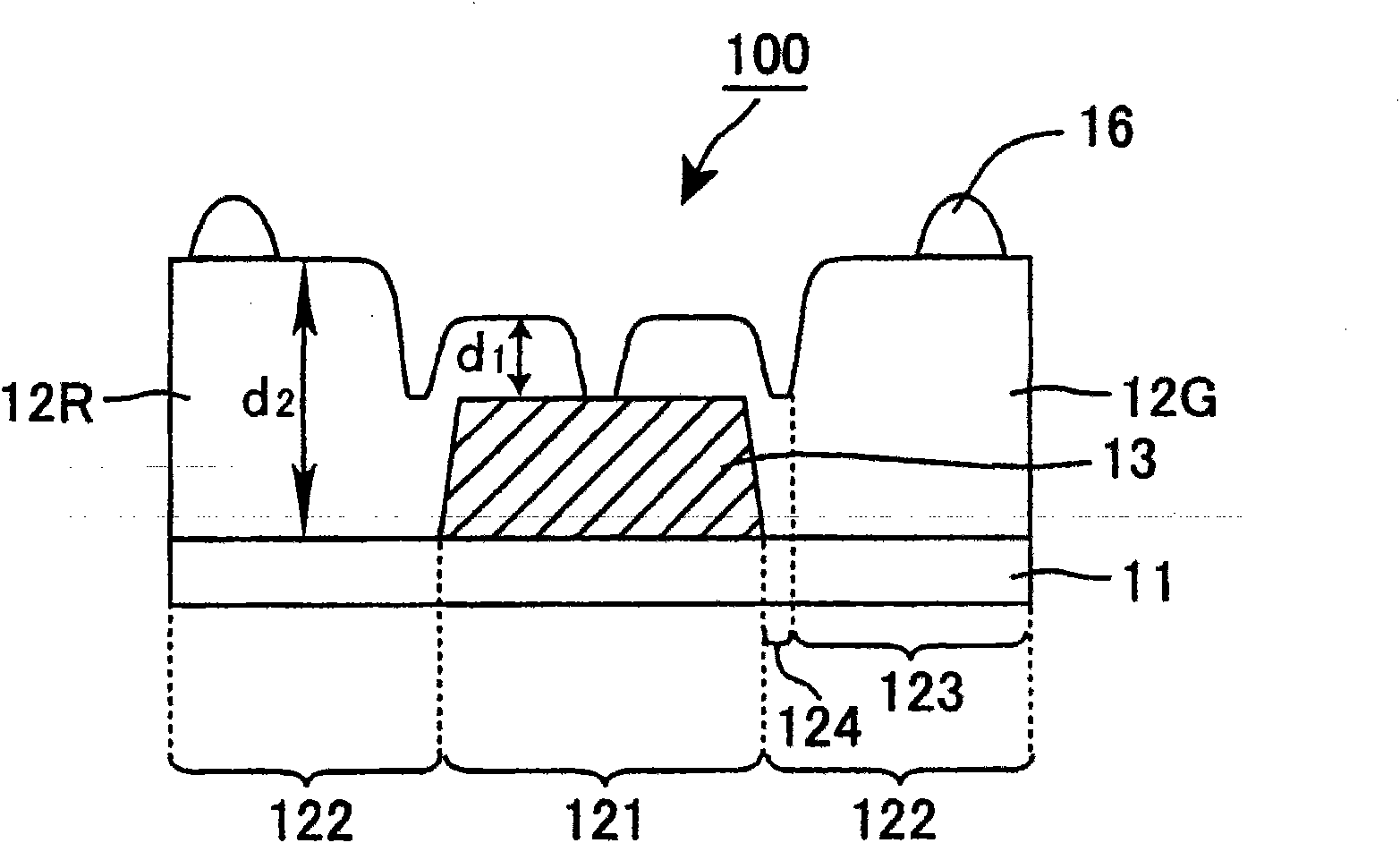

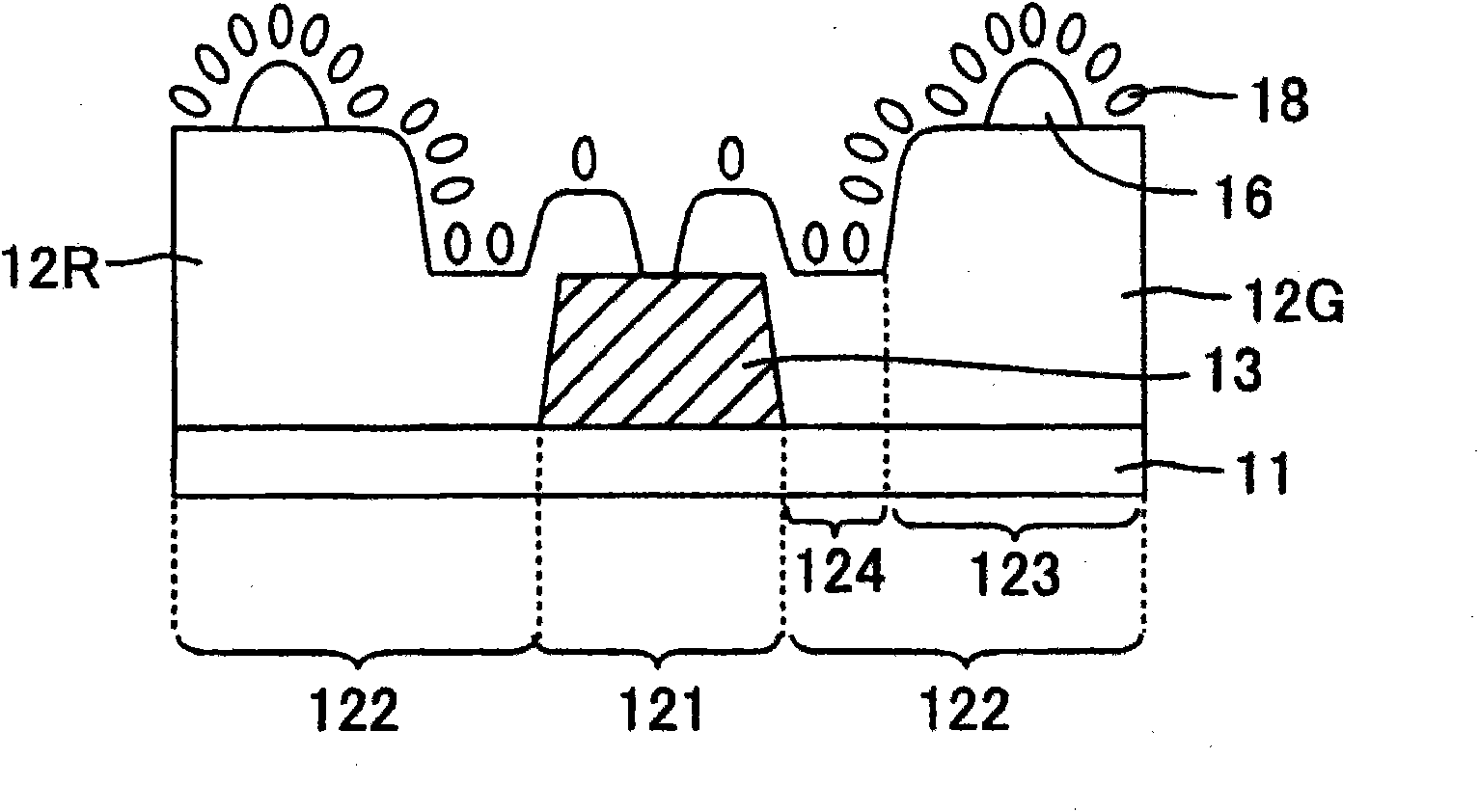

[0085] Figure 5 It is a schematic cross-sectional view showing the structure of the color filter substrate of the second embodiment.

[0086] Such as Figure 5 As shown, the structure of the color filter substrate 200 of Embodiment 2 is based on the sum of the thickness of the light-shielding layer 23 and the thickness of the red colored layer 22R or the green colored layer 22G disposed on the light-shielding layer 23, and the thickness of the red colored layer 22G disposed on the light-transmitting region. The thickness of the red coloring layer 22R or the green coloring layer 22G of 222 is formed so that the thickness is equal, and other things are the same as that of Embodiment 1.

[0087] In the color filter substrate 200, a light-shielding layer 23 with a film thickness of 1 μm is disposed on a transparent substrate 21, and a red coloring layer 22R or a green coloring layer is disposed from a light-transmitting region 222 where no light-shielding layer 23 is disposed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com