Tunnel double upper sidewall heading construction method

A construction method and tunnel technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of multiple blocks, high cost, and large disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

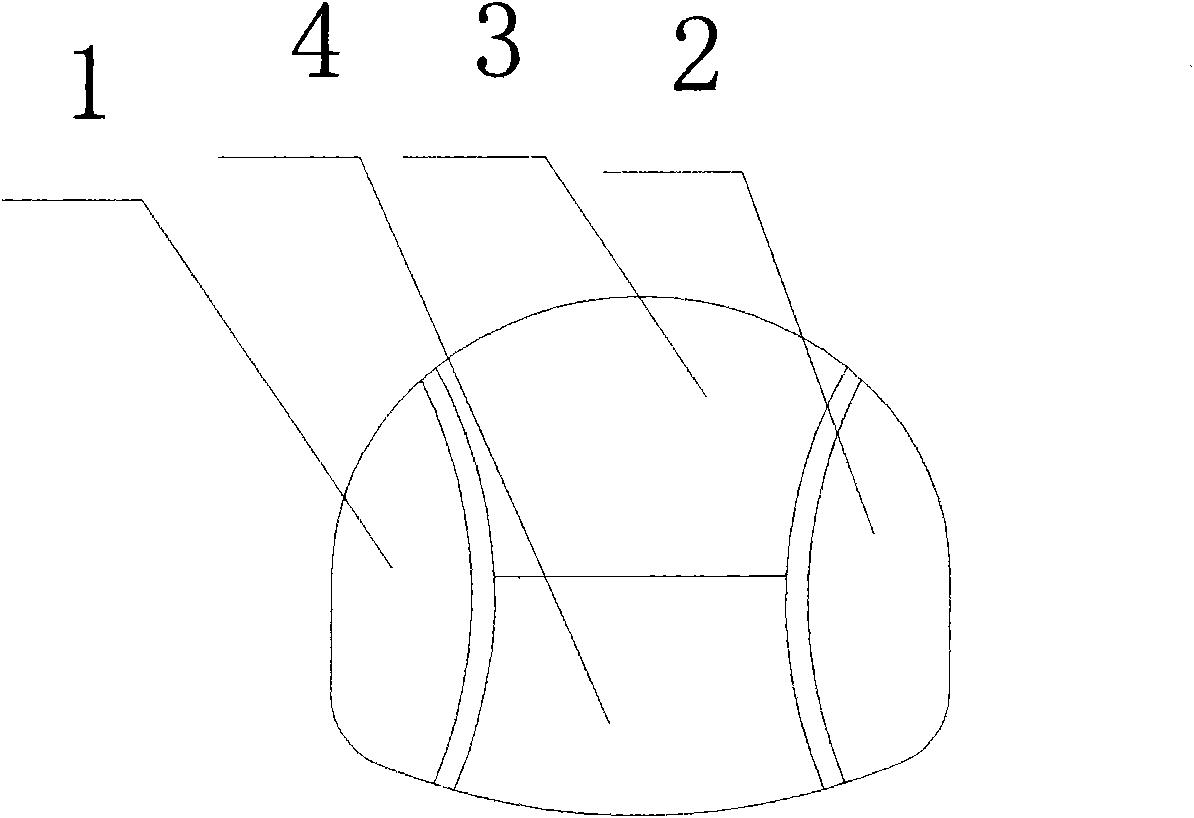

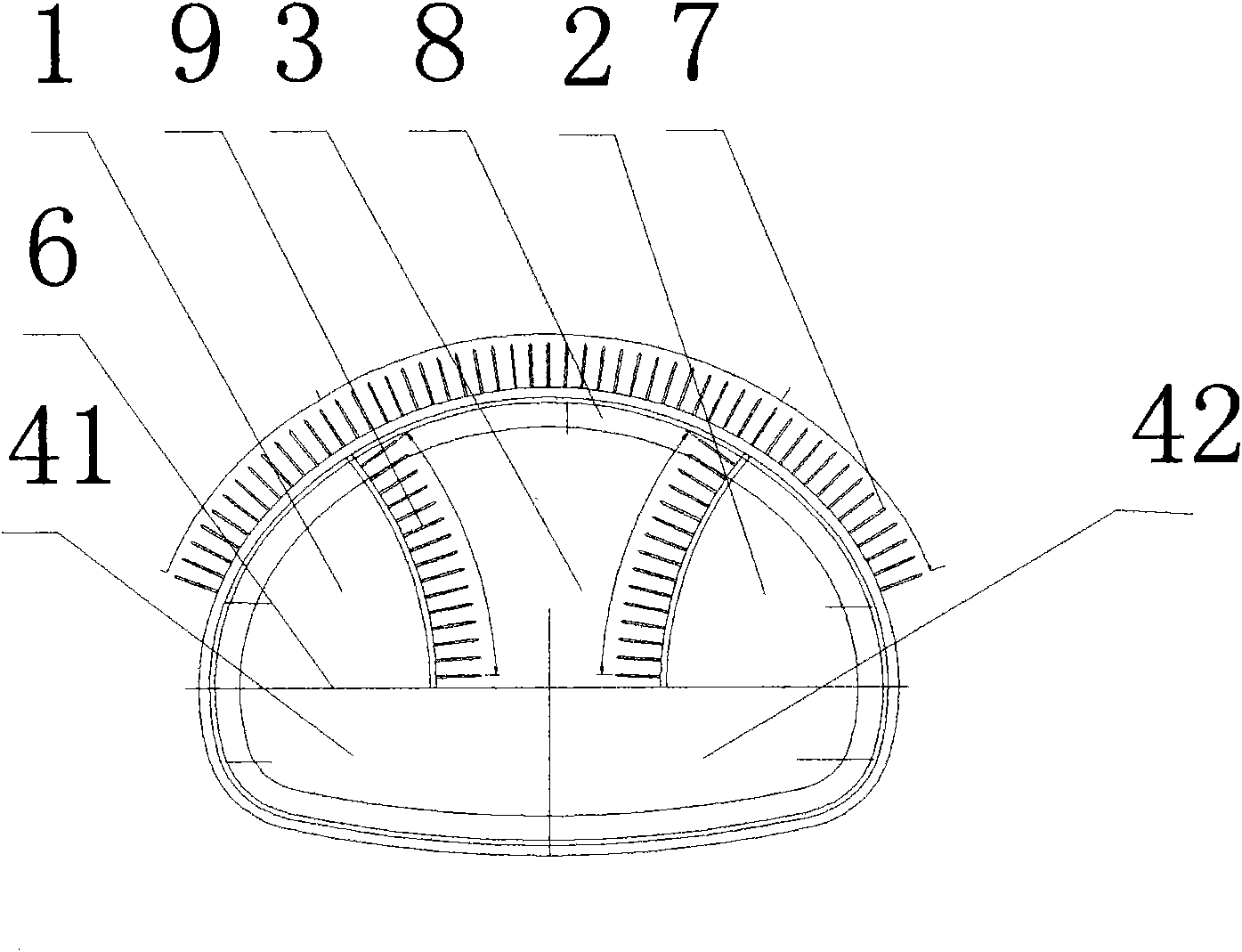

[0033] Embodiment 1. This embodiment is a method for constructing a large-span tunnel with double upper and side walls. This embodiment is a method for constructing a large-span tunnel with a span exceeding ten meters. When this method is excavated, The tunnel cross section is divided into No. 1 pilot pit 1, No. 2 pilot pit 2, upper core soil 3, No. 1 lower step 41 and No. 2 lower step 42 to excavate in time, as figure 2 As shown, the No. 1 pilot pit 1 and the No. 1 lower step 41, the boundary line between the No. 2 pilot pit 2 and the No. 2 lower step 42 is the arch line 6, and the excavation process includes the following steps:

[0034] A. Clean the face of the tunnel, determine the excavation surface, and set the advance support 7;

[0035] The advance support 7 is divided into three parts, which are respectively located on the No. 1 pilot pit 1, the upper core soil 3 and the No. 2 pilot pit 2. They can be installed together when cleaning the tunnel surface and setting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com