Fixed-length segmenting and sawing production line

A production line and sawing technology, which is applied in the direction of metal sawing equipment, sawing machine devices, sawing machine accessories, etc., can solve the problems of different sizes of tails, inability to saw, and low productivity and efficiency, so as to reduce equipment investment, The effect of reducing the time consumption of feeding materials and meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

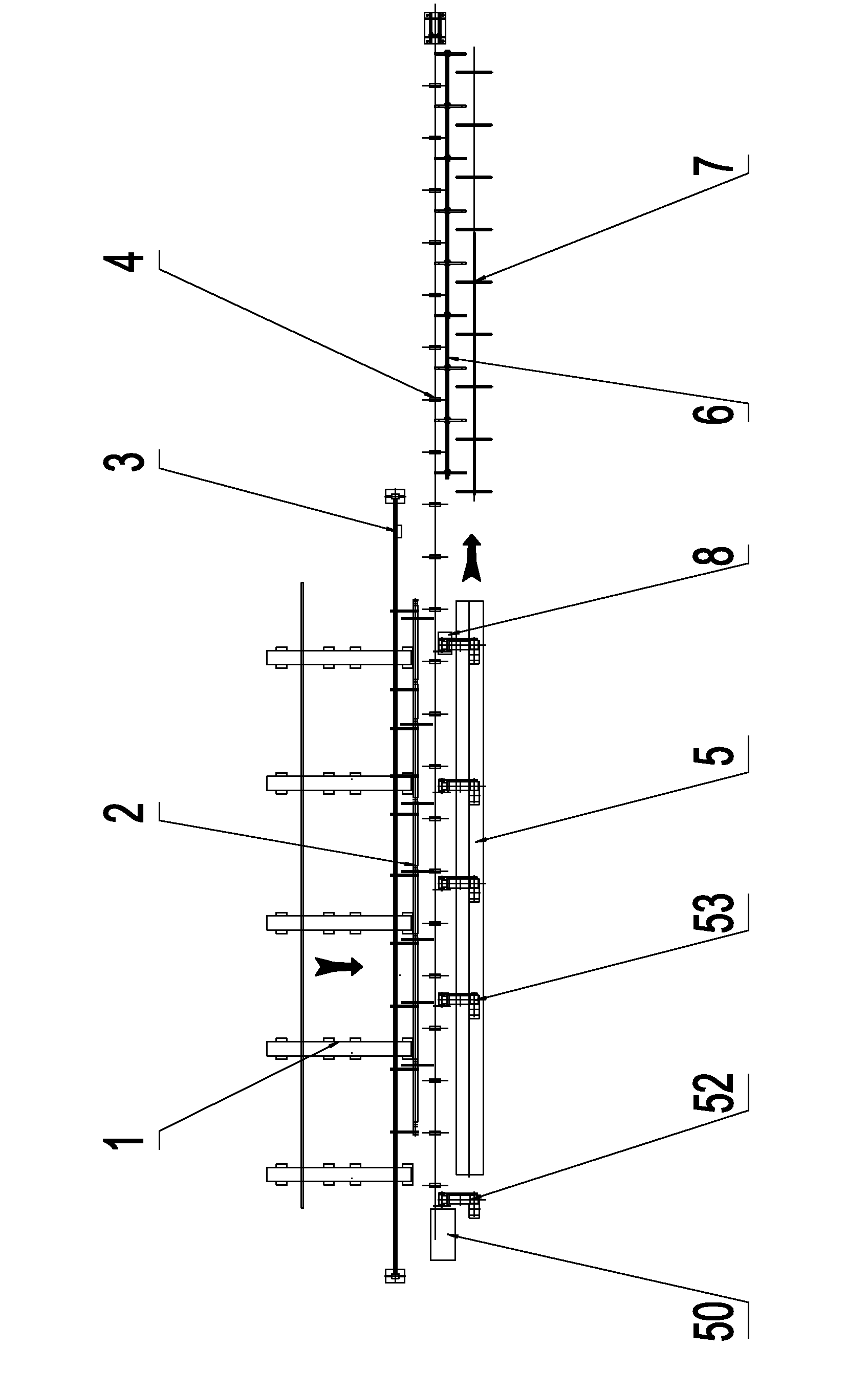

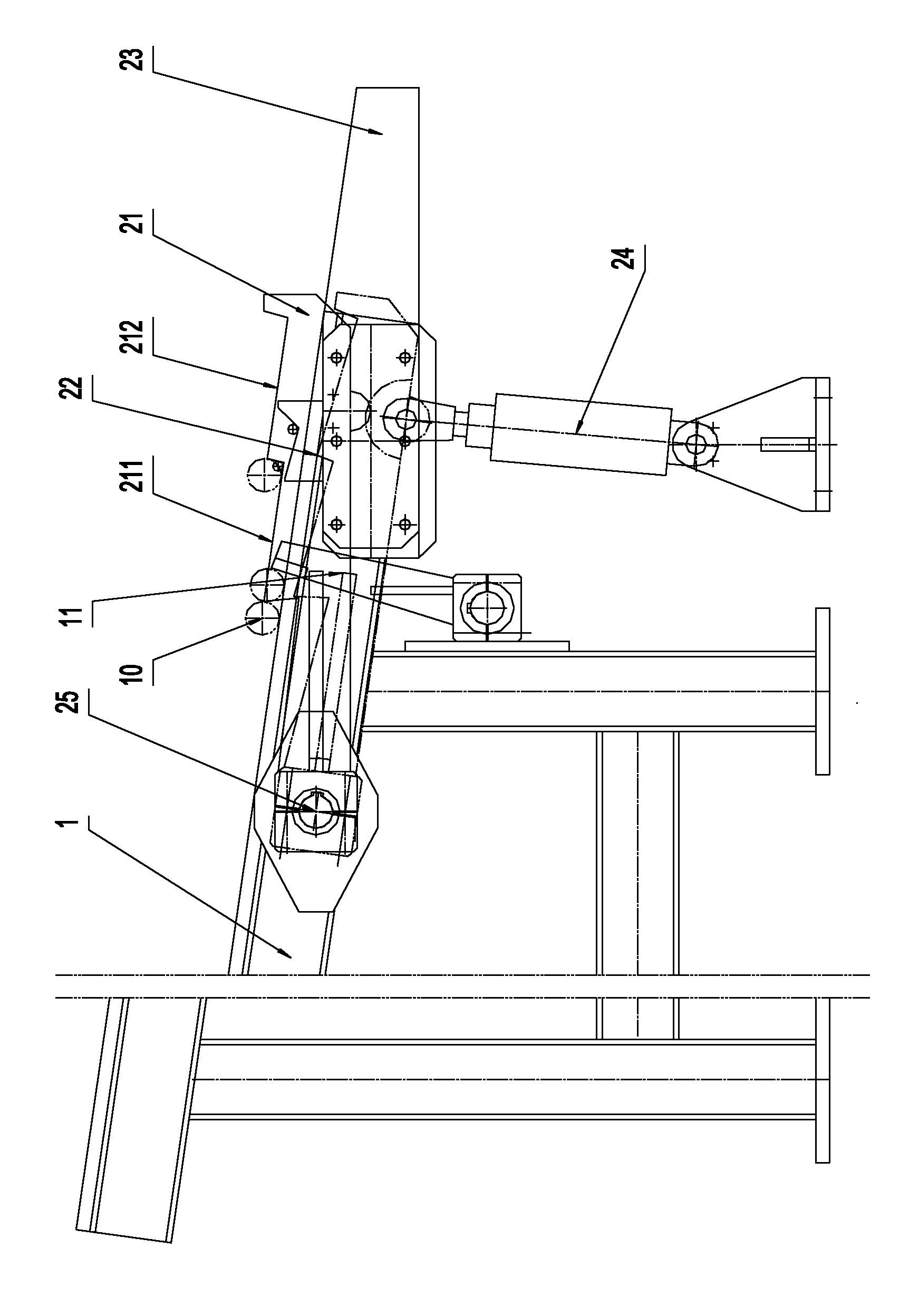

[0011] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are cited hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings: Please refer to Figure 1 to Figure 5 , a fixed-length segmental sawing production line, including a feeding platform 1, a material shifting mechanism 2, a sizing machine 3, a sawing machine 5, a conveying roller table 4, a discharging mechanism 6, a finished product collection tank 7 and a material head Collect the trolley8. The discharge end of the feeding platform 1 is provided with a baffle plate 11;

[0012] The shifting mechanism 2 includes a plurality of shifting tooth plates 21 that are hinged with the loading platform 1 through a pin shaft 25, a plurality of side-by-side fixed-to-length slots 22 that are fixed on the loading platform 1 and side-by-side A plurality of conveying sloping plates 23, the shifting tooth plate 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com