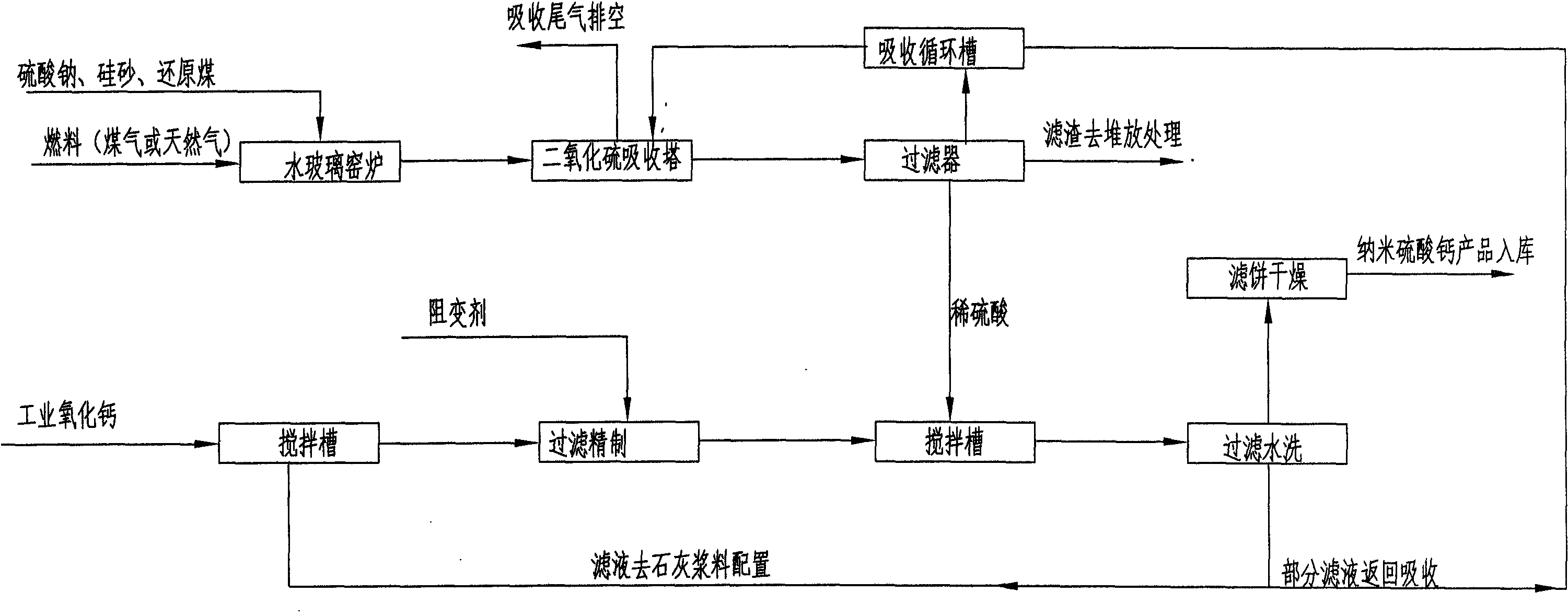

Process for preparing super-fine calcium sulfate from recycled sulfur dioxide waste gas

A technology of sulfur dioxide and calcium sulfate, which is applied in the fields of calcium/strontium/barium sulfate, chemical instruments and methods, and separation of dispersed particles, can solve problems such as sulfur dioxide pollution, and achieve the effect of reducing usage and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Take the production of 40 tons of dry process water glass per day as an example:

[0041] 1. Using sodium sulfate, silica sand, and reduced coal as raw materials, and industrial coal as fuel, heat-storage horseshoe furnace is used to produce water glass. The consumption of sodium sulfate is 0.95 tons / hour, the consumption of silica sand is 1.25 tons / hour, and the consumption of reduced coal is 0.10 tons / hour. After the material is evenly distributed, it is fed into the melting furnace at a feeding rate of 2.3 tons / hour. The flow rate of the molten water glass is 1.667 tons / hour, and the daily output of dry-process water glass is 40 tons.

[0042] 2. The temperature of the waste gas exiting the regenerative horseshoe water glass melting furnace is 320°C, the volume concentration of carbon dioxide is 3.1%, and the flow rate of the waste gas is 4736Nm / h

[0043] 3. The exhaust gas enters the absorption tower, and 25% sulfuric acid is formed in the absorption tower. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com