Asarin composite freeze-dried powder for injection

A technology of freeze-dried powder injection and asarum, applied in freeze-drying delivery, drug combination, powder delivery and other directions, can solve the problems of many types of excipients, unsatisfactory reconstitution effect, and large proportion of excipients added, so as to improve the Dissolving properties, reducing the amount of excipients, and ensuring the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Composed of:

[0046] Asarum 8.0g

[0047] 95% ethanol 40ml

[0048] Mannitol 80.0g

[0049] Add water for injection to 1000ml

[0050]

[0051] Make 500 vials after freeze-drying.

[0052] (1) preparing polysorbate-80 mass percent is 0.1% deionized aqueous solution as anti-solvent;

[0053] (2) preparation mass percentage is the diethyl ether solution of 0.1g / ml Asarone as solvent;

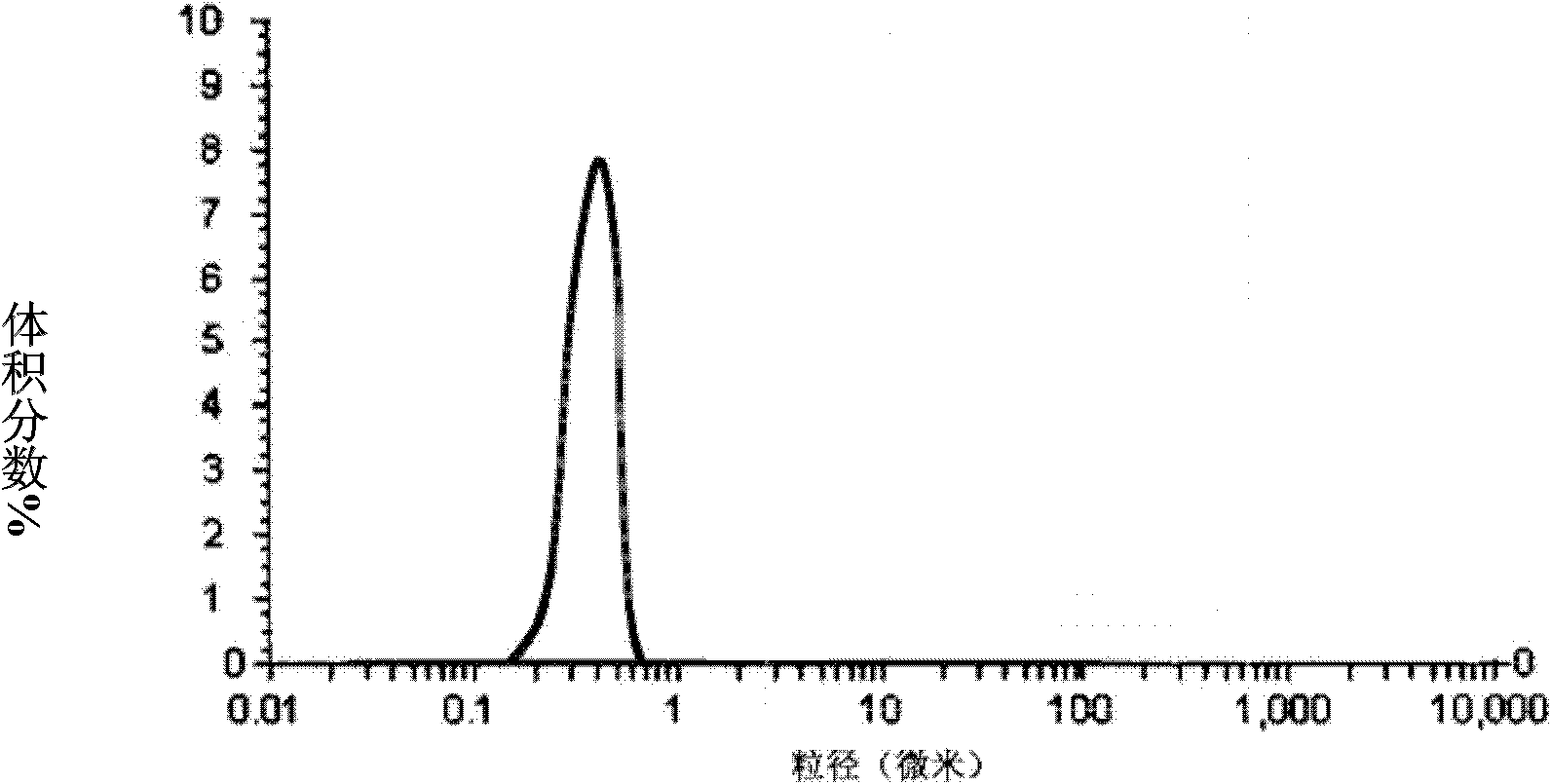

[0054] (3) Under the conditions of 2~6°C and a stirring speed of 600 rpm, quickly add solvent to the anti-solvent, wherein the volume ratio of solvent to anti-solvent is 1:15; after white crystals are produced, put the crystals and the solution at 42°C Conditioned under aging 2 hours, through filtering, washing, filter cake dispersion and spray drying; Gained ultrafine particle asarone obtains CSD curve and figure 1 same;

[0055] (4) dissolving the ultrafine particle Asarum solution in 95% ethanol in proportion to obtain liquid A;

[0056] (5) D...

Embodiment 2

[0059] The prescription is:

[0060] Asarum 8.0g

[0061] 100% ethanol 80ml

[0062] Mannitol 80.0g

[0063] Add water for injection to 1000ml

[0064]

[0065] Make 500 vials after freeze-drying.

[0066] (1) prepare polysorbate-80 mass percentage as the deionized aqueous solution of 0.5% as anti-solvent;

[0067] (2) preparation mass percentage is the diethyl ether solution of 1g / ml Asarone as solvent;

[0068] (3) Under the conditions of 6°C and a stirring speed of 1200 rpm, quickly add solvent to the anti-solvent, wherein the volume ratio of solvent to anti-solvent is 1:21; after white crystals are produced, put the crystals and the solution at 55°C Aging for 5 hours, through filtration, washing, filter cake dispersion and spray-drying, the ultrafine particle asarone of gained obtains CSD curve and figure 1 same;

[0069] (4) dissolving the ultrafine particle Asarum solution in 100% ethanol in proportion to obtain liquid A;

[0070] ...

Embodiment 3

[0073] The prescription is:

[0074] Asarum 6.0g

[0075] 98% ethanol 40ml

[0076] Mannitol 24.0g

[0077] Add water for injection to 1000ml

[0078]

[0079] Make 500 vials after freeze-drying.

[0080] (1) preparing polysorbate-80 mass percentage is the deionized aqueous solution of 0.25% as anti-solvent;

[0081] (2) preparation mass percentage is the diethyl ether solution of 0.5g / ml Asarone as solvent;

[0082] (3) At 4°C and a stirring speed of 1000 rpm, quickly add solvent to the anti-solvent, wherein the volume ratio of solvent to anti-solvent is 1:20; after white crystals are produced, put the crystals and the solution at 45°C Aged for 3 hours, filtered, washed, filter cake dispersed and spray-dried; the resulting ultrafine particle asarone was obtained by a laser particle size measuring instrument with a CSD curve and figure 1 same;

[0083] (4) dissolving the ultrafine particle Asarum solution in 98% ethanol in proportion to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com