Partition insulator

An insulator, punch-through technology, applied in the installation of insulators, electrical components, busbars, etc., can solve problems such as leakage travel or reduction of insulation travel, and achieve the effect of small transition resistance, good connection and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

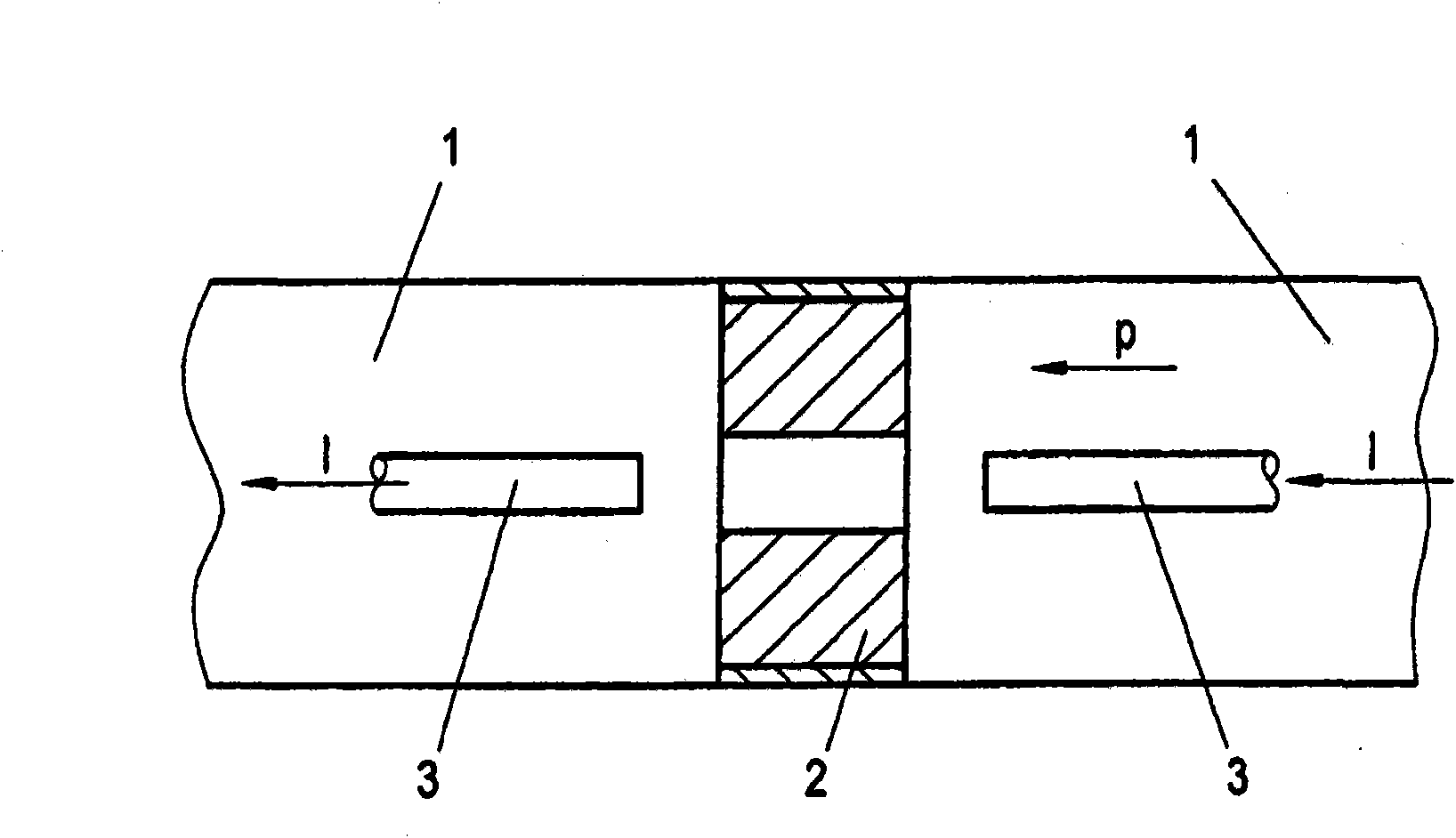

[0025] Such as figure 1 Schematically depicted, feedthrough insulators 2 serve to separate switching chambers 1 from one another in a gas-tight and pressure-resistant manner. Also in figure 1 The electric conductor 3 which can be constituted as a solid conductor or a movable separate electrode is schematically described in , and the electrical energy usually flows via the electric conductor of one switch chamber segment through the electrodes of the through insulator to the adjacent switch chamber segment Conductor. For certain operating situations the pressure of the insulating gas is only generated from one side, as this is schematically shown by the figure 1 The symbol p in represents. This requires a high mechanical strength of the feedthrough insulator 2 .

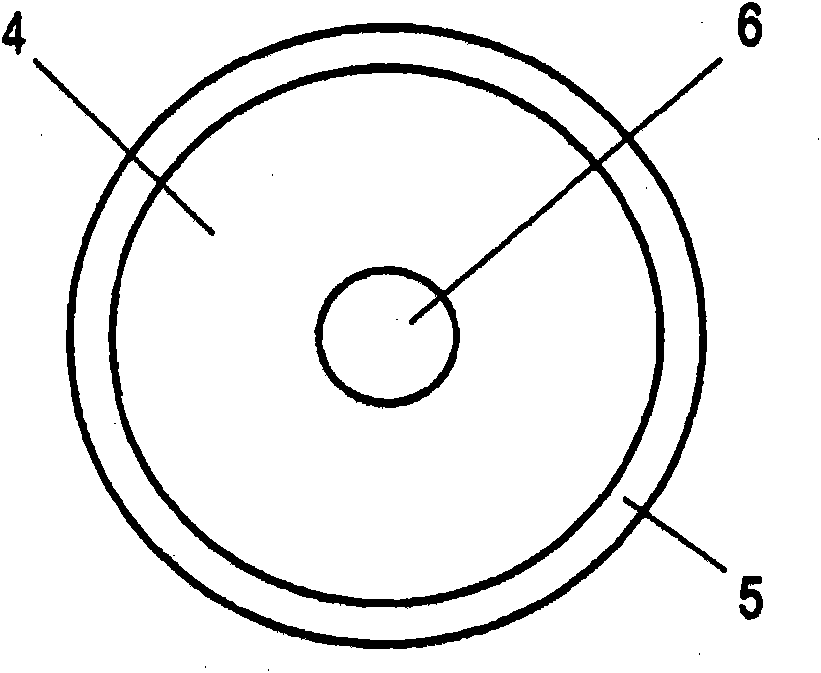

[0026] figure 2 The schematic structure of the feedthrough insulator 2 is shown. The feedthrough insulator comprises an insulator 4 , for example made of epoxy resin, which is usually cast into a metal flange 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com