Petroleum coke direct burner

A burner and petroleum coke technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of short main combustion zone, high carbon content of petroleum coke, and incomplete combustion of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

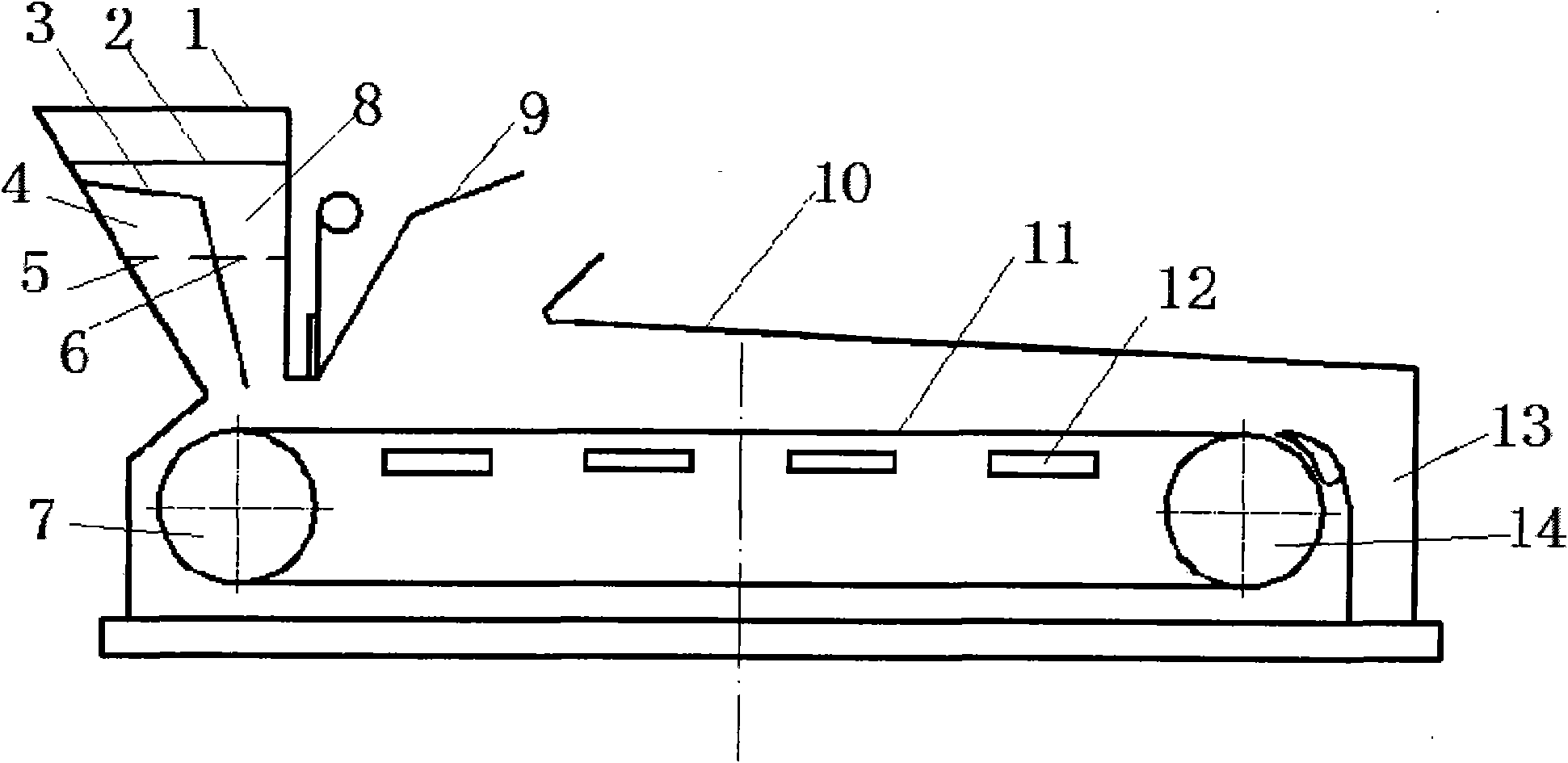

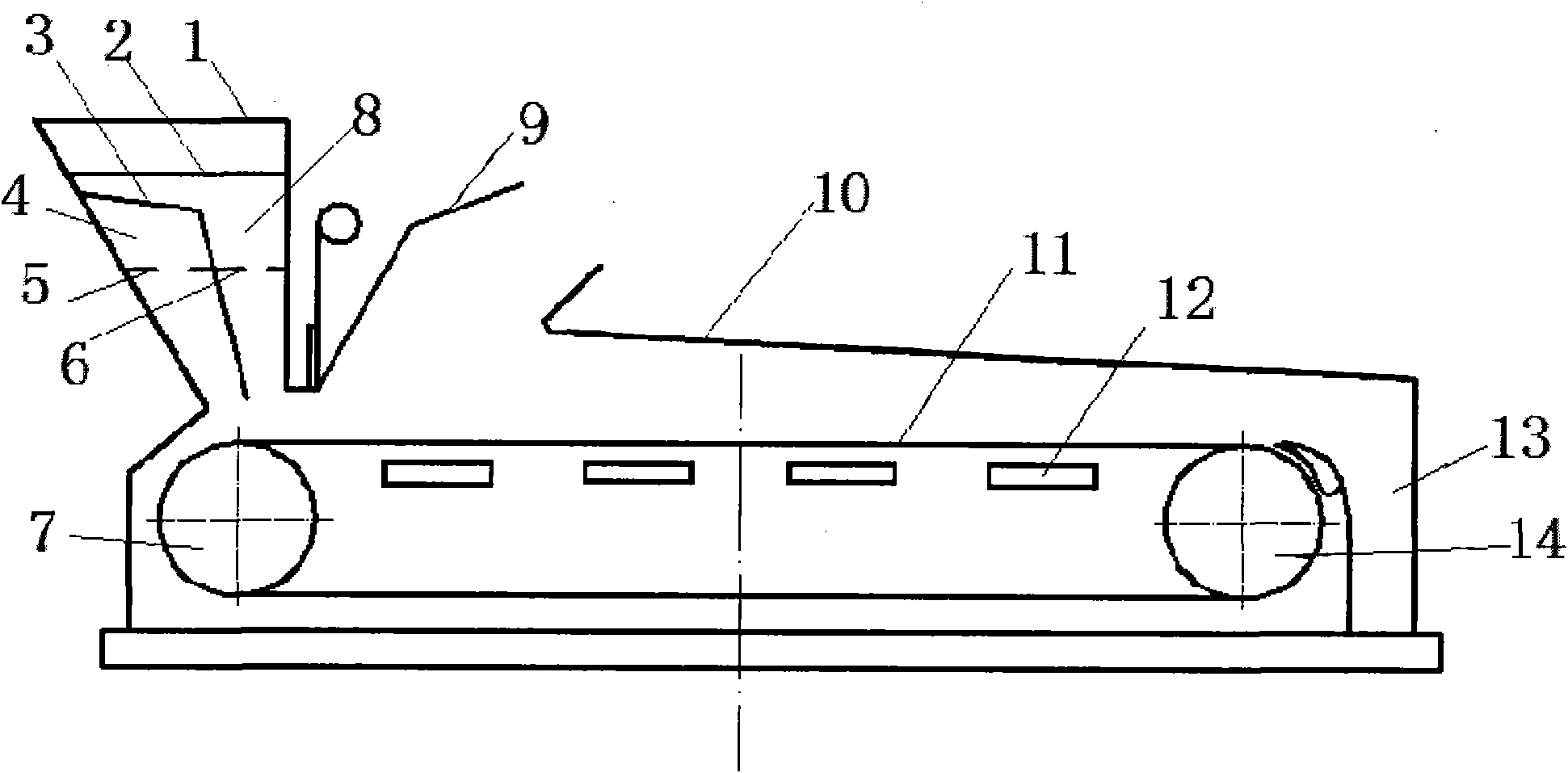

[0016] Such as figure 1 As shown, the present invention includes a hopper 1, a fire grate 11, an air chamber 12, and a slag outlet 13. The fire grate 11 is driven to rotate by a driving shaft 7 and a driven shaft 14, and a front arch 9 is arranged on the upper front wall, and a rear wall There is a rear arch 10 on it, in order to promote fuel ignition and combustion; the front arch 9 is relatively high, the rear arch 10 is long and low, and the angle is relatively flat. The rear arch 10 uses heat-resistant and wear-resistant materials. The slag discharge channel 13 is located between the fire grate 11 and the rear wall. There are several air chambers 12 located below the fire grate 11. The hopper 1 is arranged outside the front wall, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com