Quick cooling device of hot mill

A rapid cooling and cooling device technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of product surface wrinkles, affecting product quality, unstable product width, etc., and achieve the effect of smooth appearance and avoid shrinkage and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

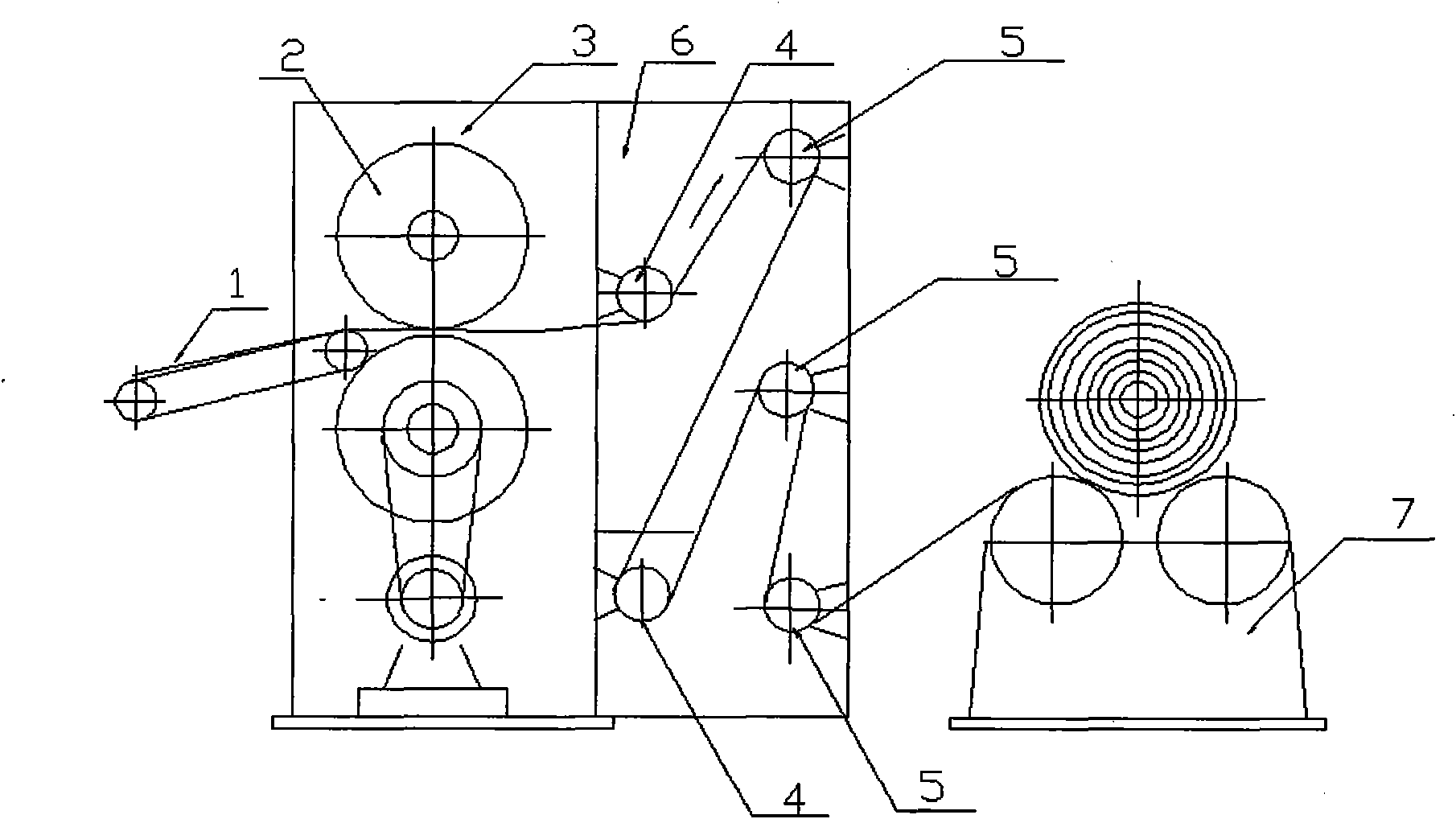

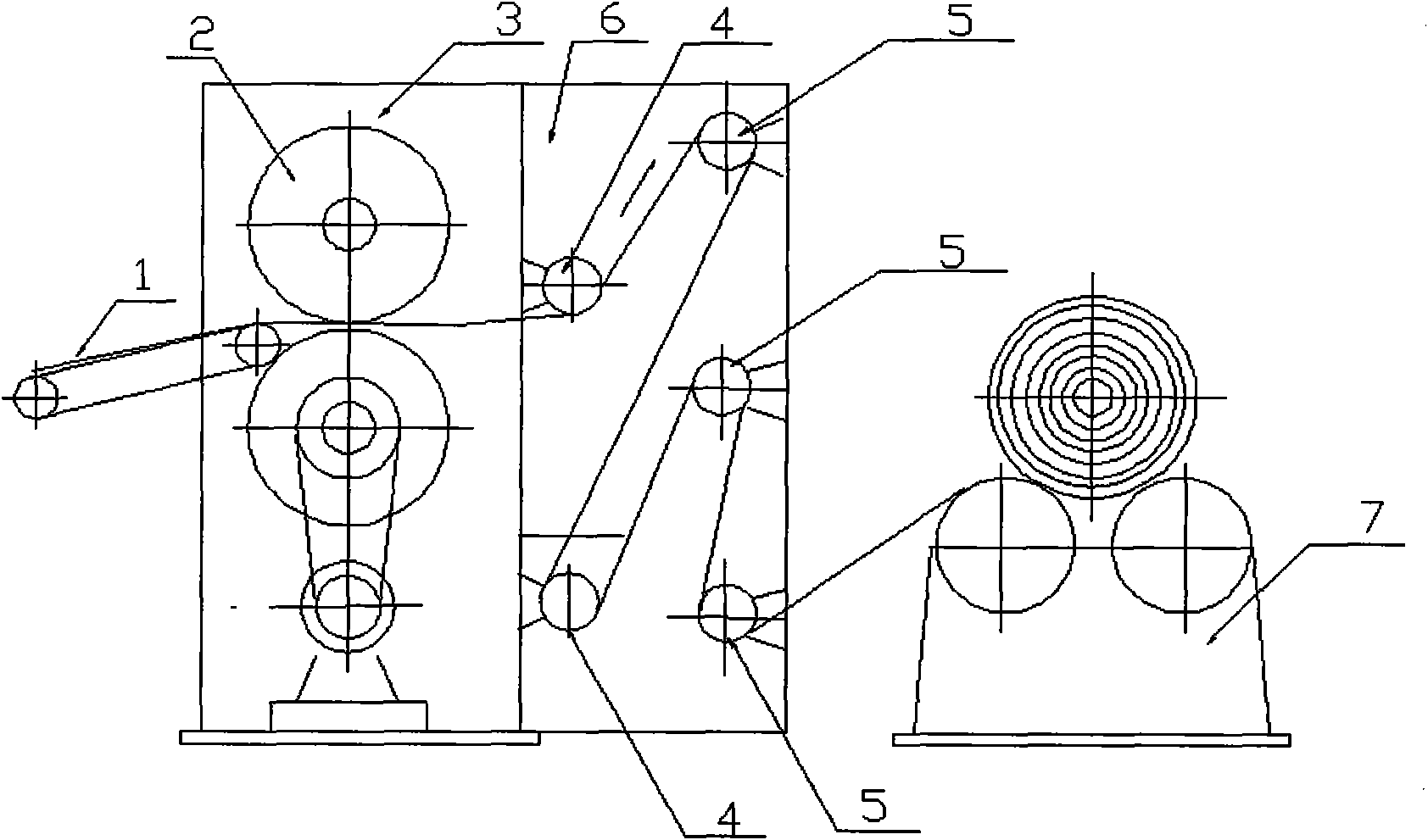

[0012] Such as figure 1 The hot rolling mill rapid cooling device shown includes a cooling device frame 6, two cooling rolls 4, and three cloth guide rolls 5. One side of the cooling device frame 6 is connected with a hot rolling mill roll 3, and the hot rolling mill roll Two hot rolling mill rolls 2 are installed on the 3, and the two hot rolling mill rolls are carried out hot rolling through belt transmission, and the other side of the cooling device frame 6 is connected with a cloth winding machine 7, and the two cooling rolls 4 are respectively installed on At the junction of the hot rolling mill frame and the cooling device frame, three cloth guide rollers 5 are respectively installed on the opposite sides of the two cooling rollers 4. The steel pipe is processed and the outer surface is chrome-plated. The cooling water enters from one end of the cooling roll body and flows out from the other end. The cooling water circulates in the two cooling rolls to keep the surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com