Glass fiber reinforced gypsum product, and preparation method and equipment thereof

A glass fiber and gypsum technology, which is applied in the field of glass fiber reinforced gypsum products for architectural decoration and its preparation, can solve the problems of partial fracture of gypsum, no improvement in strength and toughness, etc., so as to improve performance, improve production efficiency and qualified product rate, Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

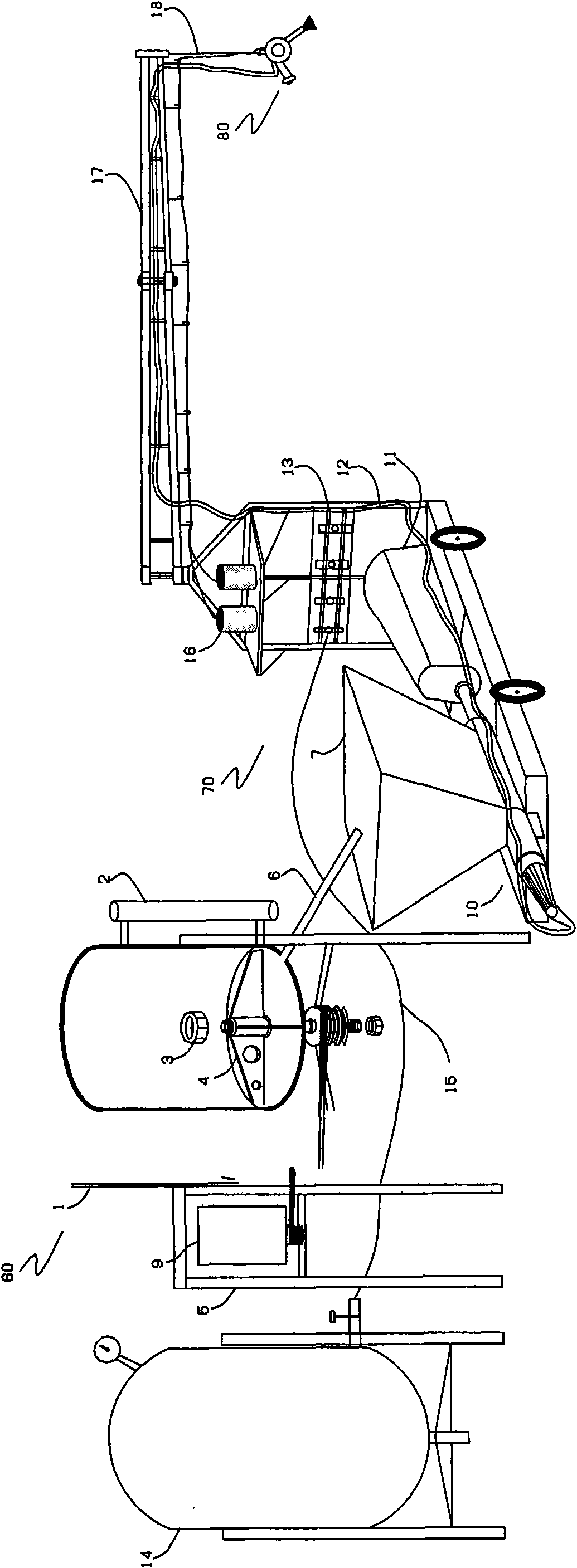

[0034] The apparatus for manufacturing the glass fiber reinforced gypsum product of the present invention includes a stirring mixing apparatus 60 , an atomizing apparatus 70 and a shear jet apparatus 80 .

[0035] Such as figure 1 As shown, the stirring and mixing device 60 includes a cylinder 1 , a doser 2 , a mixing and stirring blade 4 , a fixing frame 5 and a motor 9 . The cylinder body 1 is fixed on the fixing frame 5, and the doser 2 is arranged on the side of the cylinder body 1 for adding additives into the cylinder body 1. The mixing blade 4 is fixed on the end of a shaft by a set screw 3 . The shaft is rotatably installed in the sleeve at the bottom of the cylinder body 1 . The motor 9 drives the shaft to rotate through a belt transmission mechanism, and the mixing blade 4 fixedly installed at the end of the shaft stirs and mixes the materials added into the barrel 1 .

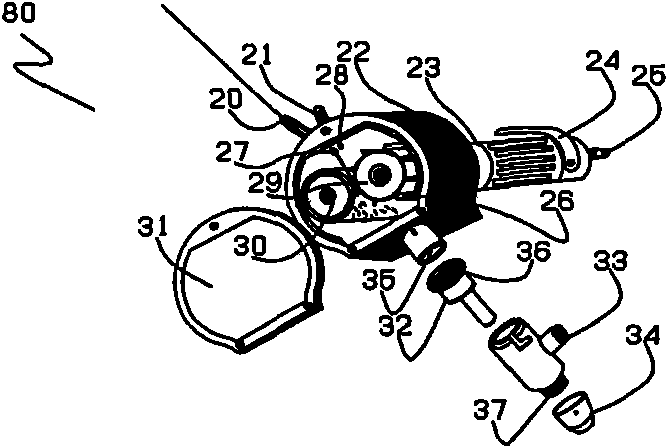

[0036] Such as figure 2 As shown, the atomization device 70 includes a motor 11, a screw con...

Embodiment 2

[0049] The basic steps of this embodiment are the same as those of Example 1, and the difference from Example 1 is that the raw material components and weight are taken by weighing in Table 2.

[0050] Table 2

[0051] components

Embodiment 3

[0053] The basic steps of this embodiment are the same as those of Example 1, and the difference from Example 1 is that the raw material components and weight are taken by weighing in Table 3.

[0054] table 3

[0055] components

[0056] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com