Steam generator core

A steam generator and core technology, applied in steam generation, steam generation methods, steam boilers, etc., can solve the problems of difficult production and assembly, unreasonable structure, burns, etc., and achieve the goal of increasing heat utilization and improving the external environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

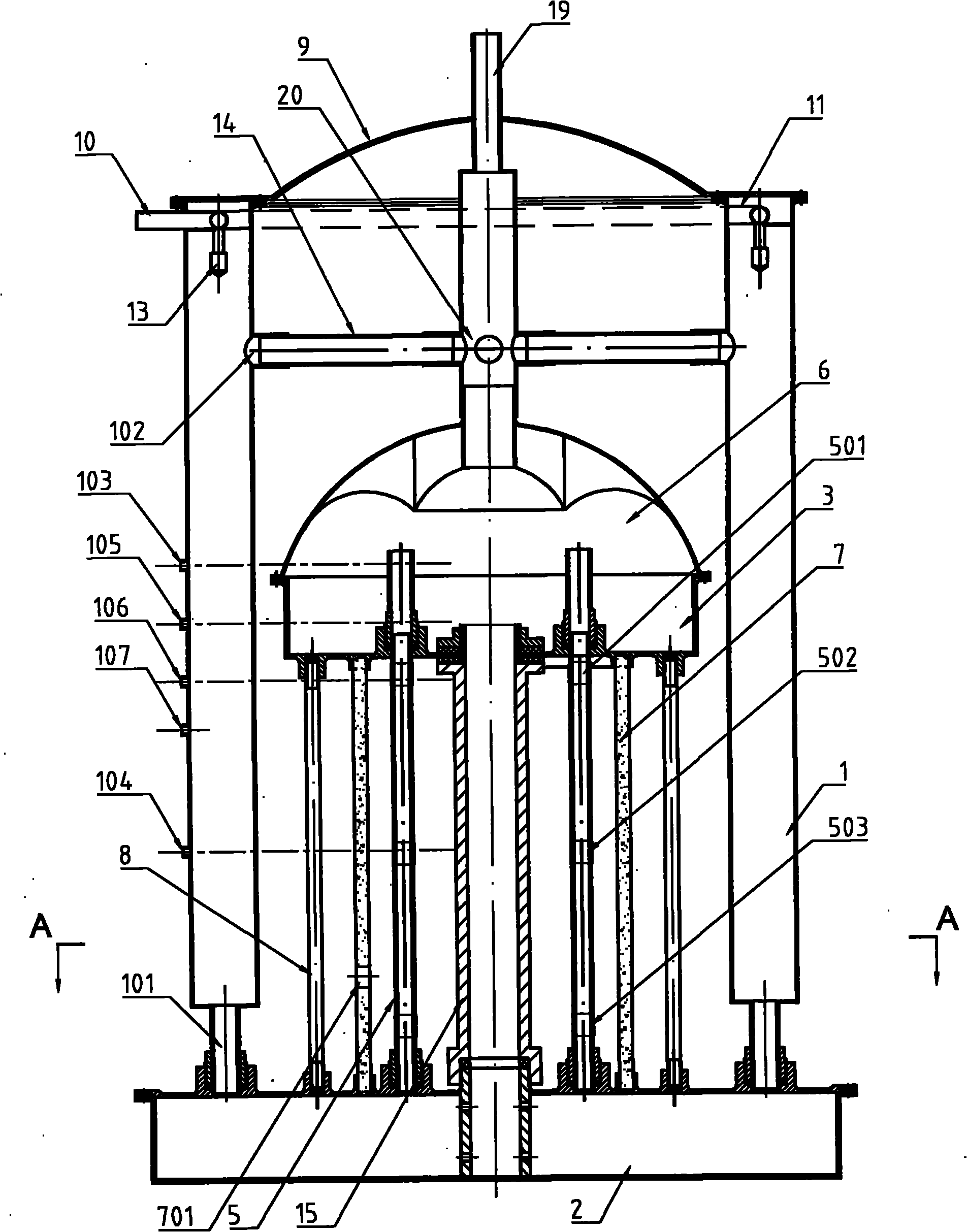

[0028] exist Figure 3 to Figure 6 In the shown embodiment of the steam generator core of the present invention, the steam generator core includes a water inlet pipe 10, a water inlet tank 1, a lower water tank 2, a steam-water separator, 4 heating pipes 5, a water return pipe 15 and ceramic separators. Hot body7.

[0029] The steam-water separator comprises a loam cake 6 and a lower water tank 3, and the loam cake 6 closes the upper part of the steam-water separator to form a steam chamber.

[0030] The heating tube 5 is a non-metallic electric heating tube, which can be a quartz electric heating tube or a ceramic electric heating tube. The quartz electric heating tube or the ceramic electric heating tube is made of a tubular matrix made of quartz or ceramics. The conductive layer is formed, and there is an electrode made of silver powder, which is divided into an upper electrode and a lower electrode. According to the power configuration, there can also be an intermediate e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com