Numerical control groove grinding machine with numerical control grinding wheel trimming device

A grinding wheel dressing and grooving machine technology, applied in abrasive surface adjustment devices, manufacturing tools, grinding machine parts, etc., can solve the problems of inapplicability of diamond pens, damage, interference, etc., achieve simple structure, improve dressing accuracy, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

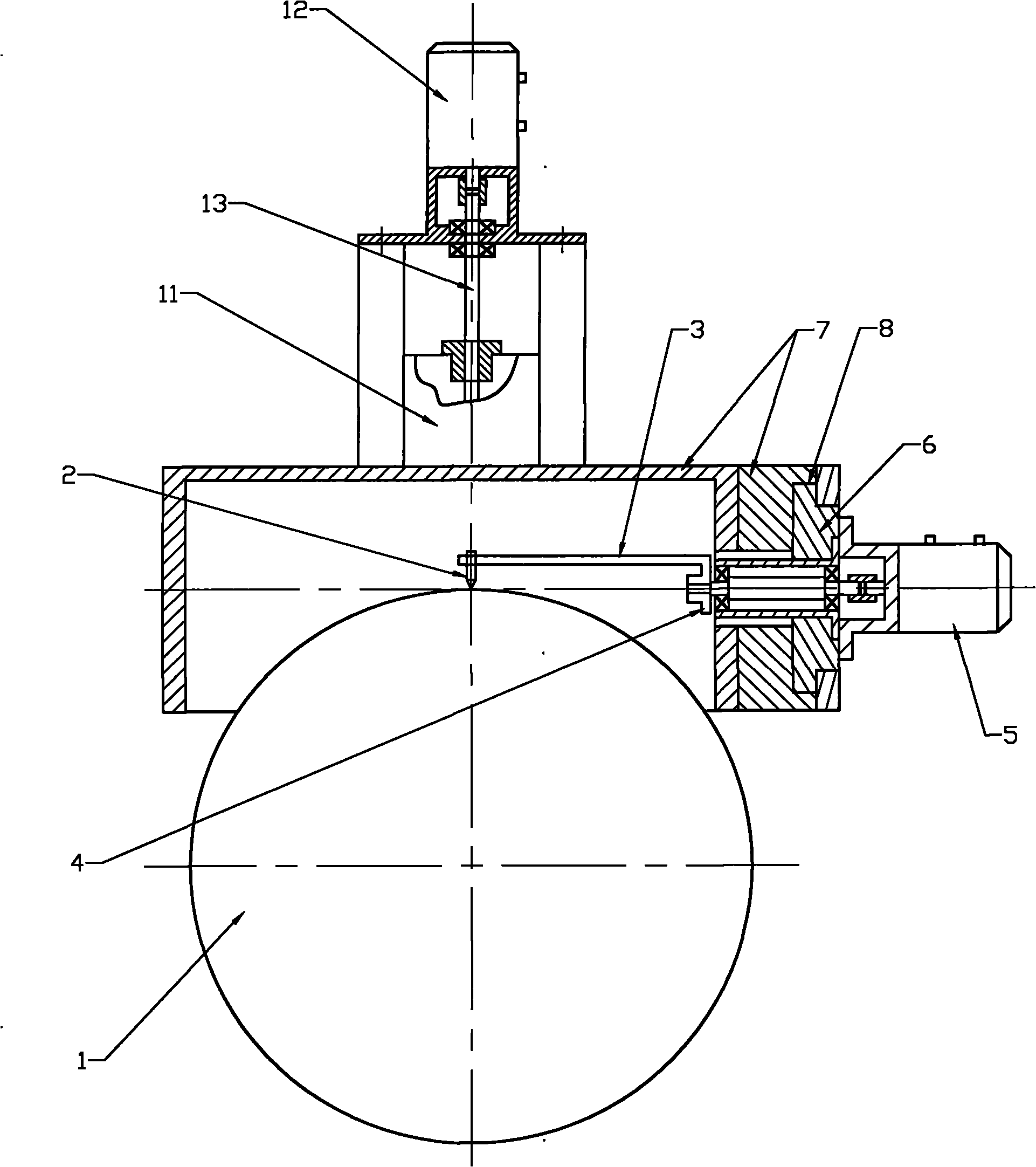

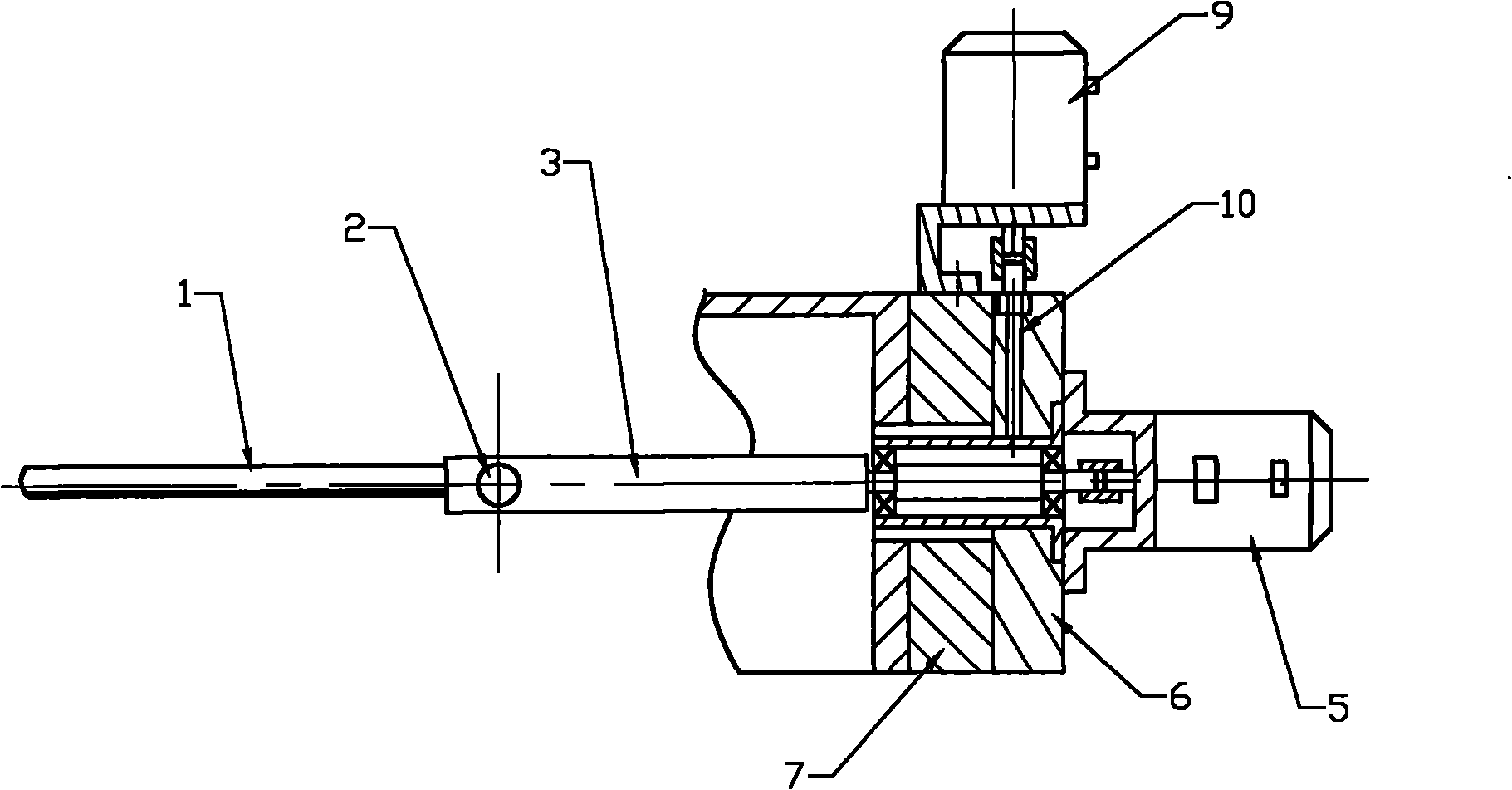

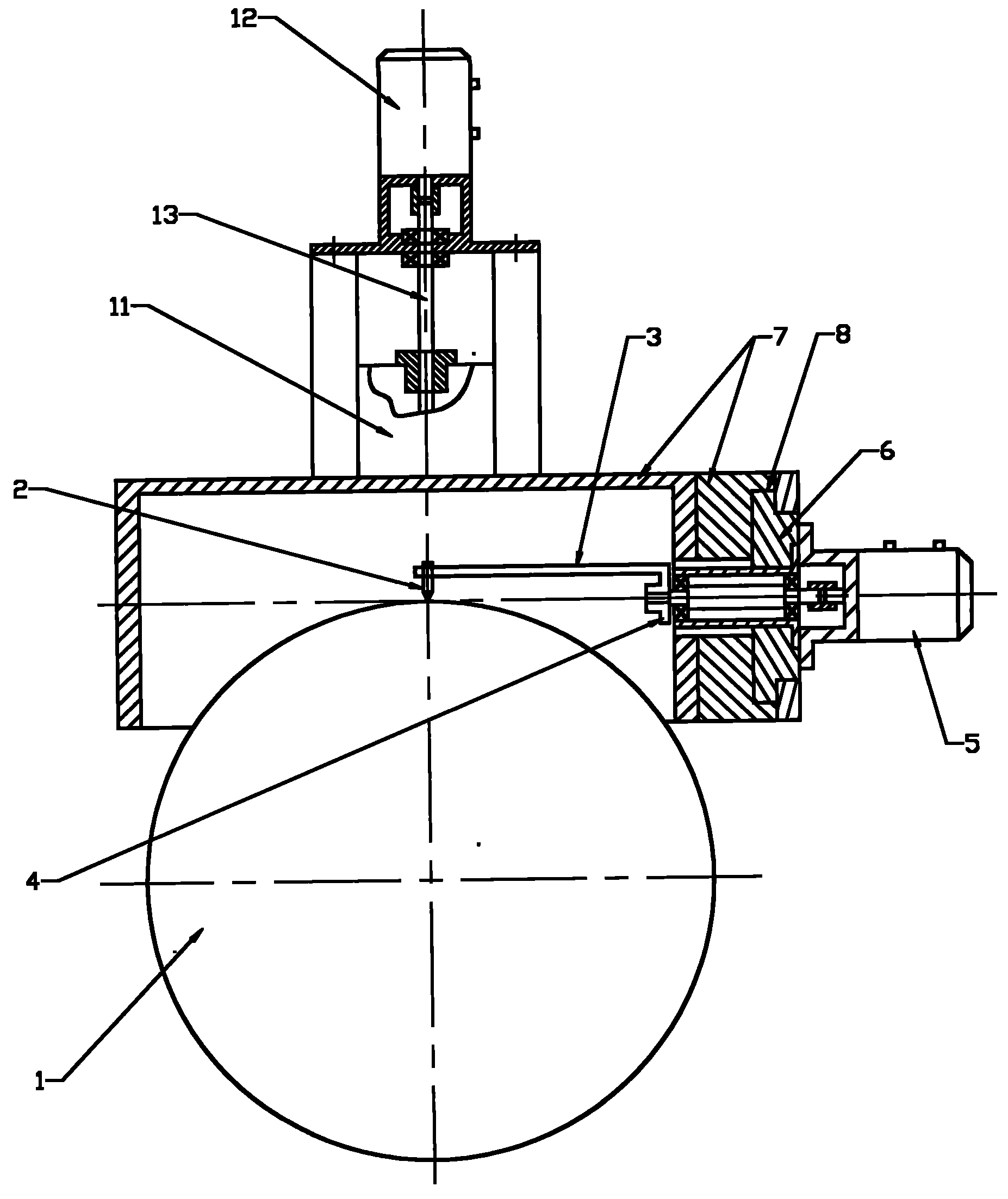

[0012] The groove grinding machine of the present invention includes a grinding head part for grinding grooves, a lifting part for controlling the lifting of the grinding head, a main shaft transmission part for controlling the movement of the workpiece, and a trimming part for trimming the edge section of the grinding head and the grinding wheel. , coordinating parts such as the numerical control system of each part action (not given in the figure); As shown in the figure, the dressing part includes the diamond pen 2 that is positioned at the top of the grinding wheel 1, and the diamond pen is installed on the side of a horizontal rotating arm 3 The front end and the rear end of the rotating arm 3 are connected to the edge of a turntable 4 with a horizontal shaft, and the turntable is driven by a rotating numerical control motor 5; the rotating numerical control motor 5 is installed on a horizontal slider 6, and the horizontal slider is installed on a casing part 7 and can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com