Space hole optimization design method of thin-wall curved-surface structure with holes

A technology of surface structure and optimization design, which is applied to the optimization design of holes on any thin-walled surface structure in space, and the field of optimization design of space holes for thin-walled surface structures with holes, which can solve the problems of difficult analytical expression of curves and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

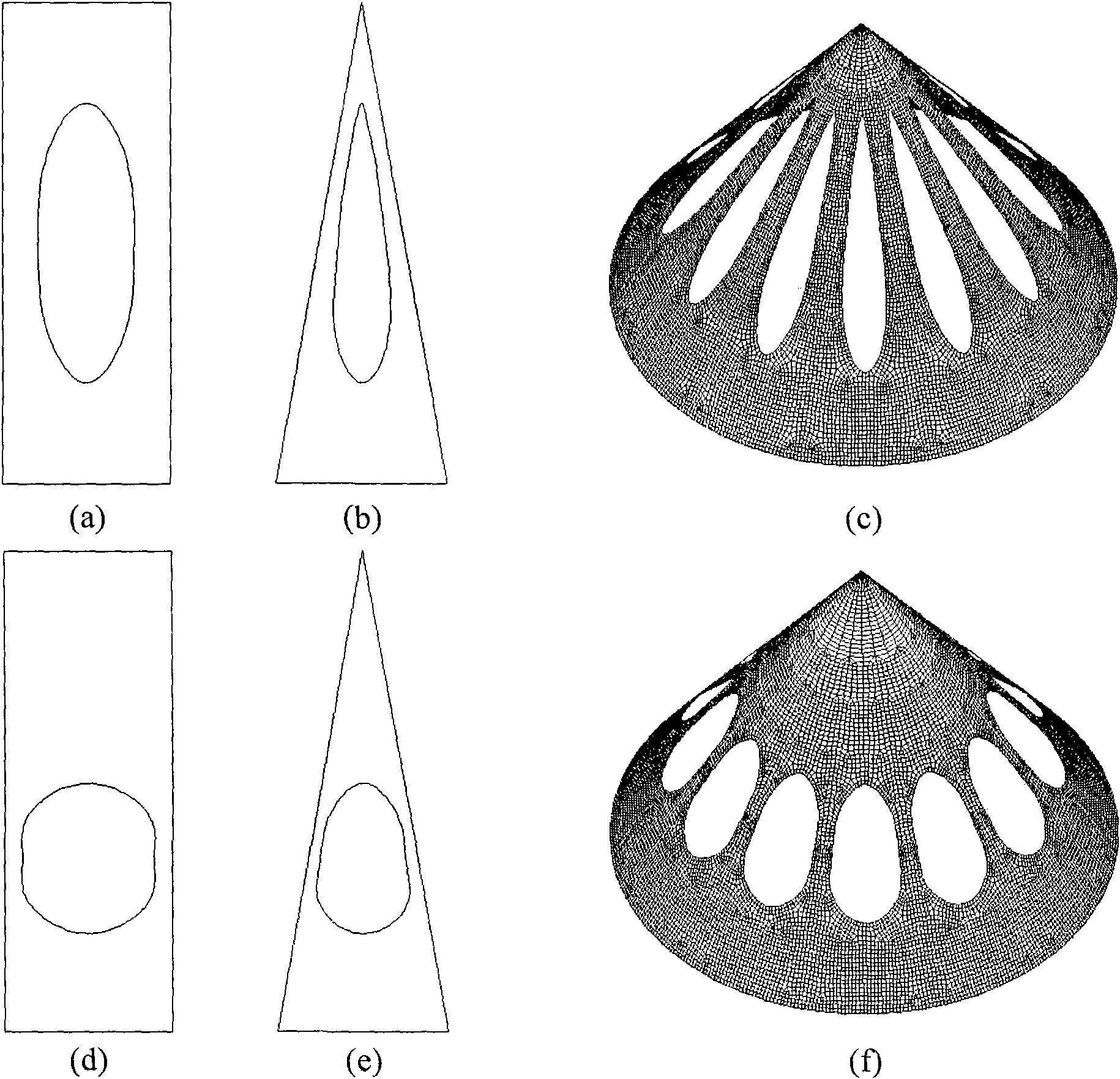

[0055] Example 1: Optimal design of hole shape on a thin-walled conical surface.

[0056] There are 12 circularly symmetrical holes on the thin-walled conical surface structure, and its basic parameters are shown in Table 1.

[0057] Table 1

[0058]

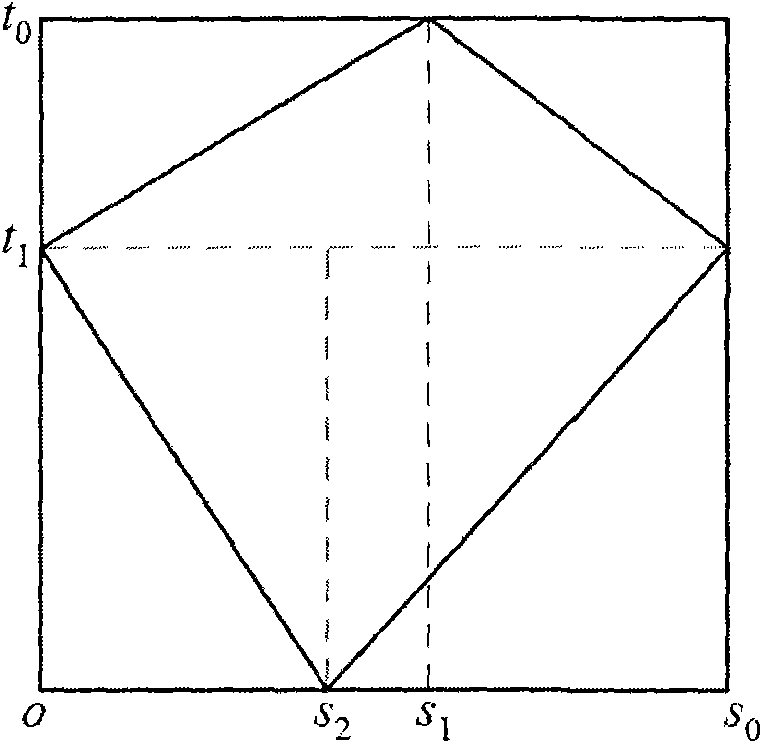

[0059] (a) Establish the parametric equation of the one-twelfth unit cell structure of the thin-walled conic surface in space:

[0060] x = 200 ( 1 - t ′ ) cos ( 1.4999 s ′ ) y = 200 ...

Embodiment 2

[0084] Example 2: Optimal design of hole shape on thin-walled hemispherical surface.

[0085] There are four circularly symmetrical holes on the thin-walled hemispherical surface structure, and its basic parameters are shown in Table 3.

[0086] table 3

[0087]

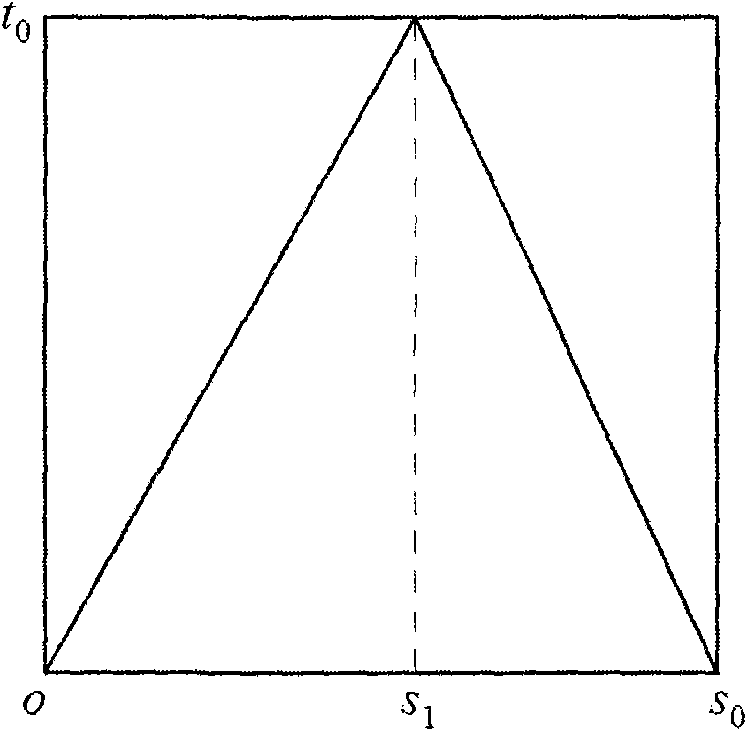

[0088] (a) Establish the parametric equation of the quarter unit cell structure of the space thin-walled hemispherical surface:

[0089] x = 300 cos 0.5 πt ′ cos 0.5 πs ′ y = 300 cos 0.5 πt ′ sin 0.5 ...

Embodiment 3

[0113] Example 3: Optimal design of hole shape on thin-walled cylindrical surface sheet.

[0114] There is a hole in the structure of the thin-walled cylindrical surface sheet, and its basic parameters are shown in Table 5.

[0115] table 5

[0116]

[0117]

[0118] (a) Establish the parametric equation of the space thin-walled cylindrical surface structure:

[0119] x = 400 cos ( 2.5 s ′ ) y = 400 sin ( 2.5 s ′ ) z ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com