Drive axle based on half-shaft bearing novel installation system

A technology of half-shaft bearings and installation systems, which is applied to axles, brakes, brake components, etc., can solve the problems of low load-bearing capacity of half-shaft bearings, and achieve the advantages of saving machining costs, high load-bearing capacity, and reduced weight and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

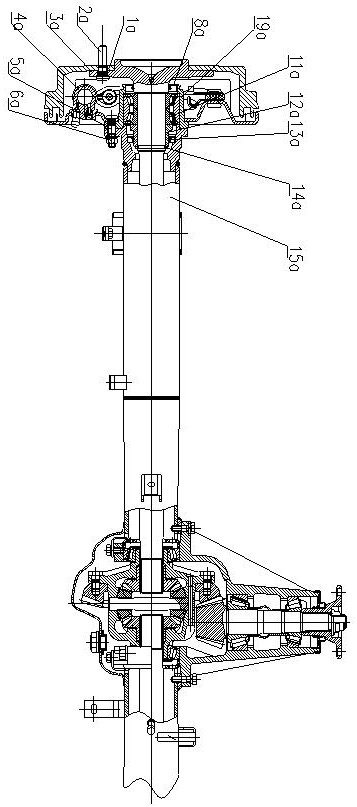

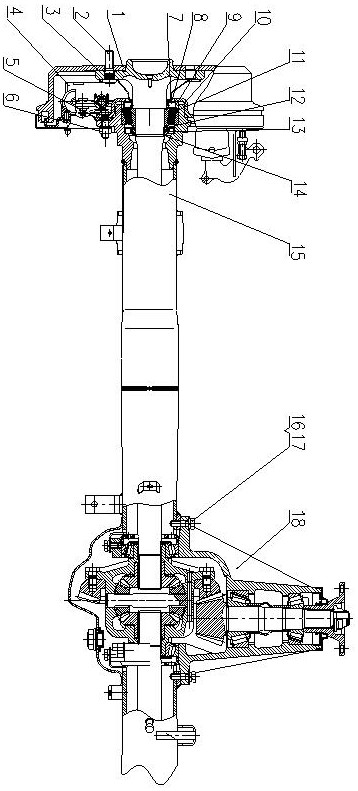

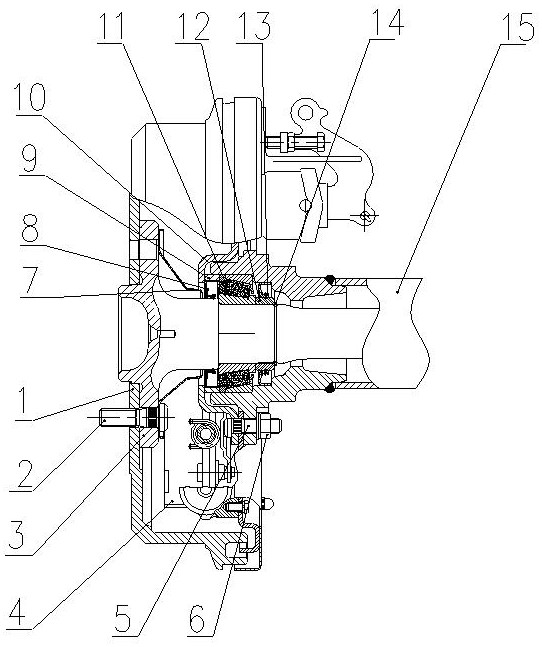

[0029] Such as Figure 2 to Figure 7 As shown, a drive axle based on a new installation system for half shaft bearings, the half shaft 3 installed on the rear axle housing assembly 15, the brake assembly 4 is installed on the half shaft 3, and the half shaft sleeved on the half shaft 3 Bearing 11, a bearing bush 12 arranged on one side of the half shaft bearing 11, an inner oil seal 13 is provided on the outer side of the bearing bush 12, and a circlip 14 is arranged on one side of the bearing bush 12, and the circlip 14 is fixed on the half shaft 3 On the other side of the half-shaft bearing 11, there is an oil seal bush 9, and the outer oil seal 8 is press-fitted inside the oil seal bush 9. One side of the oil seal bush 9 is provided with a bearing baffle 10, and the bearing baffle 10 passes through the brake assembly. 4 Press and fix the half-shaft bearing 11;

[0030] The oil deflector 7 is installed between the bearing baffle 10 and the inner end surface of the half shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com