Liquid crystal display device and manufacture method of color film substrate thereof

A technology of liquid crystal display device and color filter substrate, which is applied in the photoengraving process of the pattern surface, the original for photomechanical processing, optics, etc., and can solve the problems of TFTLCD TOUCHMURA defect, TFTLCD light leakage, poor contrast ratio, and column spacer support area. limited and other problems, to achieve the effect of preventing poor light leakage, improving stability, and avoiding movement and dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

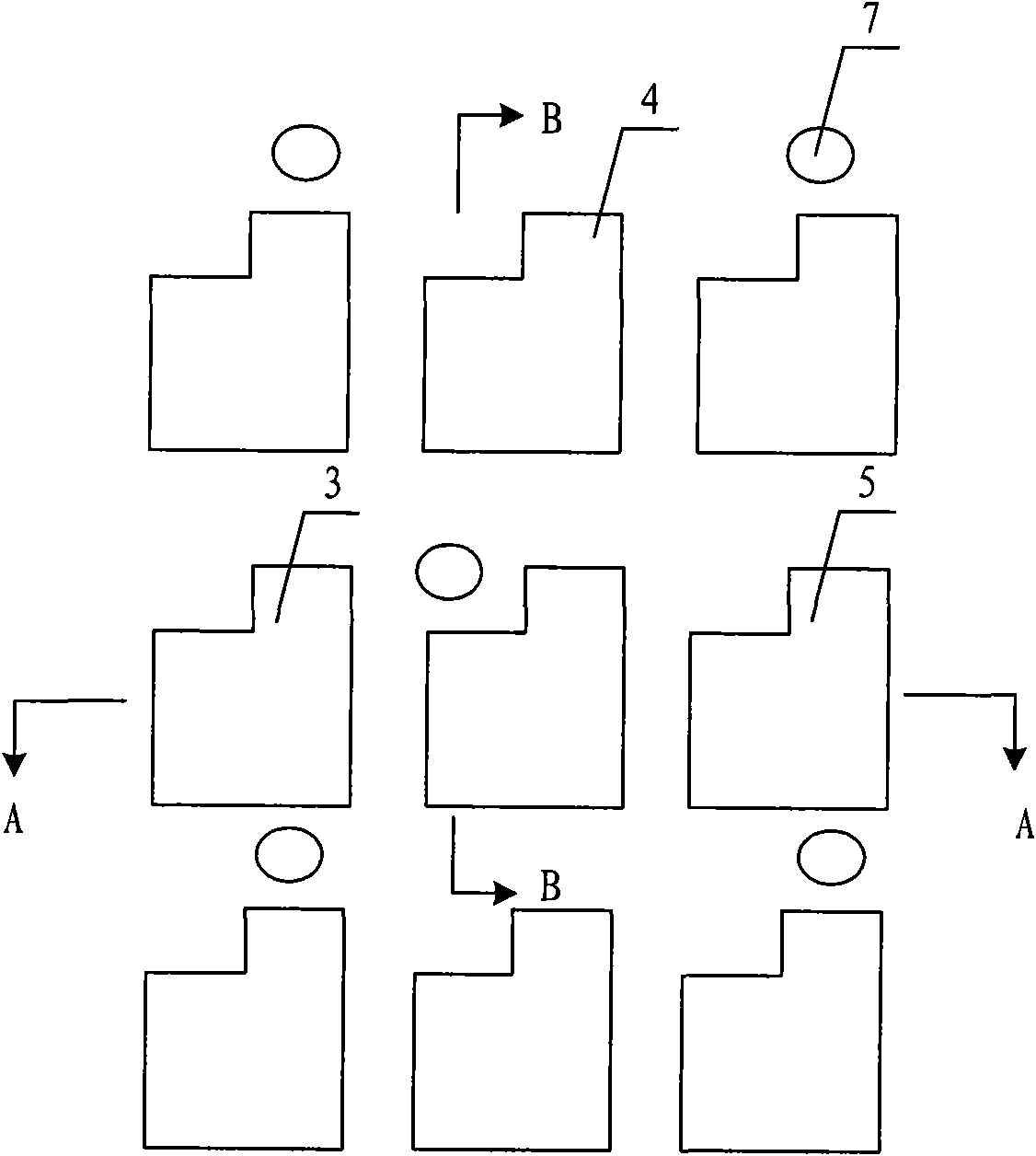

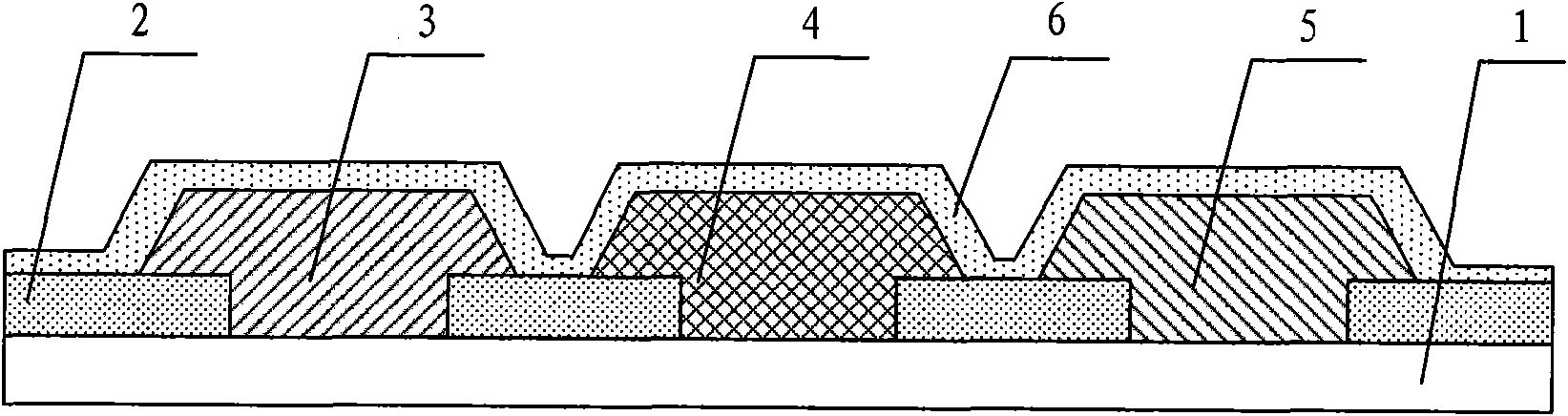

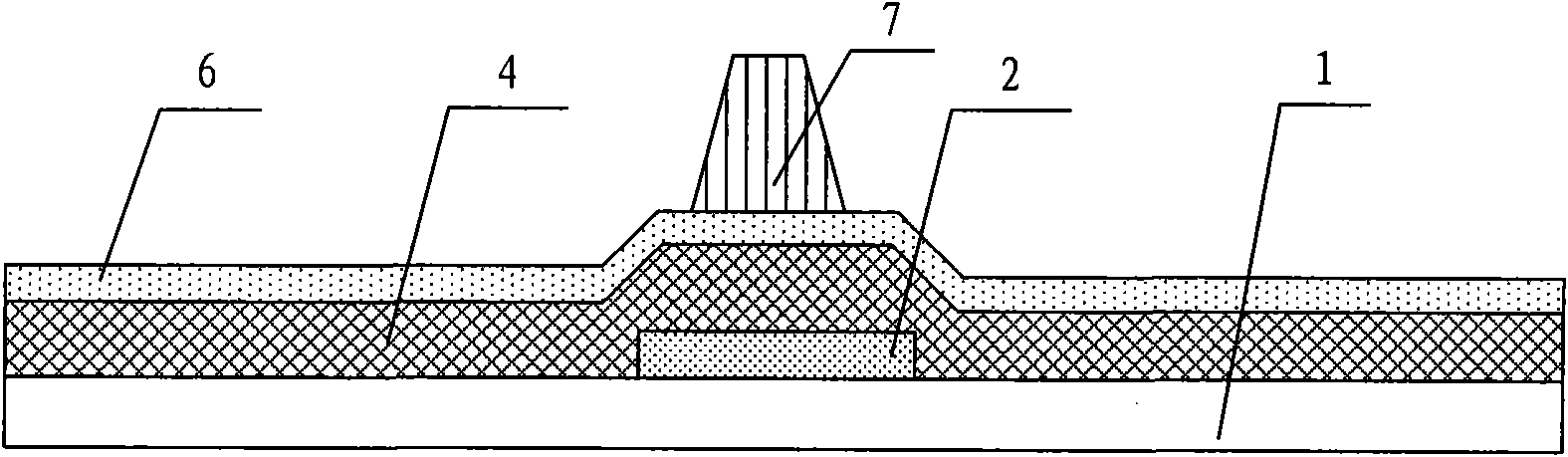

[0037] Figure 4 It is a schematic structural diagram of Embodiment 1 of the liquid crystal display device of the present invention, as Figure 4 As shown, the liquid crystal display device includes an array substrate 9 , a color filter substrate, and a liquid crystal layer 10 disposed between the array substrate 9 and the color filter substrate. Wherein, the color filter substrate includes a substrate 1 , a color pixel pattern and a black matrix pattern 2 . The color pixel pattern is arranged on the substrate 1 in matrix form, for example, Figure 4 The medium-color pixel patterns may include red pixel patterns 3 , green pixel patterns 4 and blue pixel patterns 5 . The black matrix pattern 2 may include a horizontal structure and a vertical structure. The black matrix pattern 2 is supported between the array substrate 9 and the color filter substrate and partly in contact with the array substrate 9, for shading and maintaining the distance between the array substrate 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com