Preparation method of sample for measuring semisolid injection forming mechanical property of magnesium alloy

A technology of injection molding and sample preparation, which is applied in the direction of measuring devices, scientific instruments, sampling devices, etc., can solve the problems of data fluctuation, poor accuracy and reliability, etc., and achieve the effect of fine and uniform grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

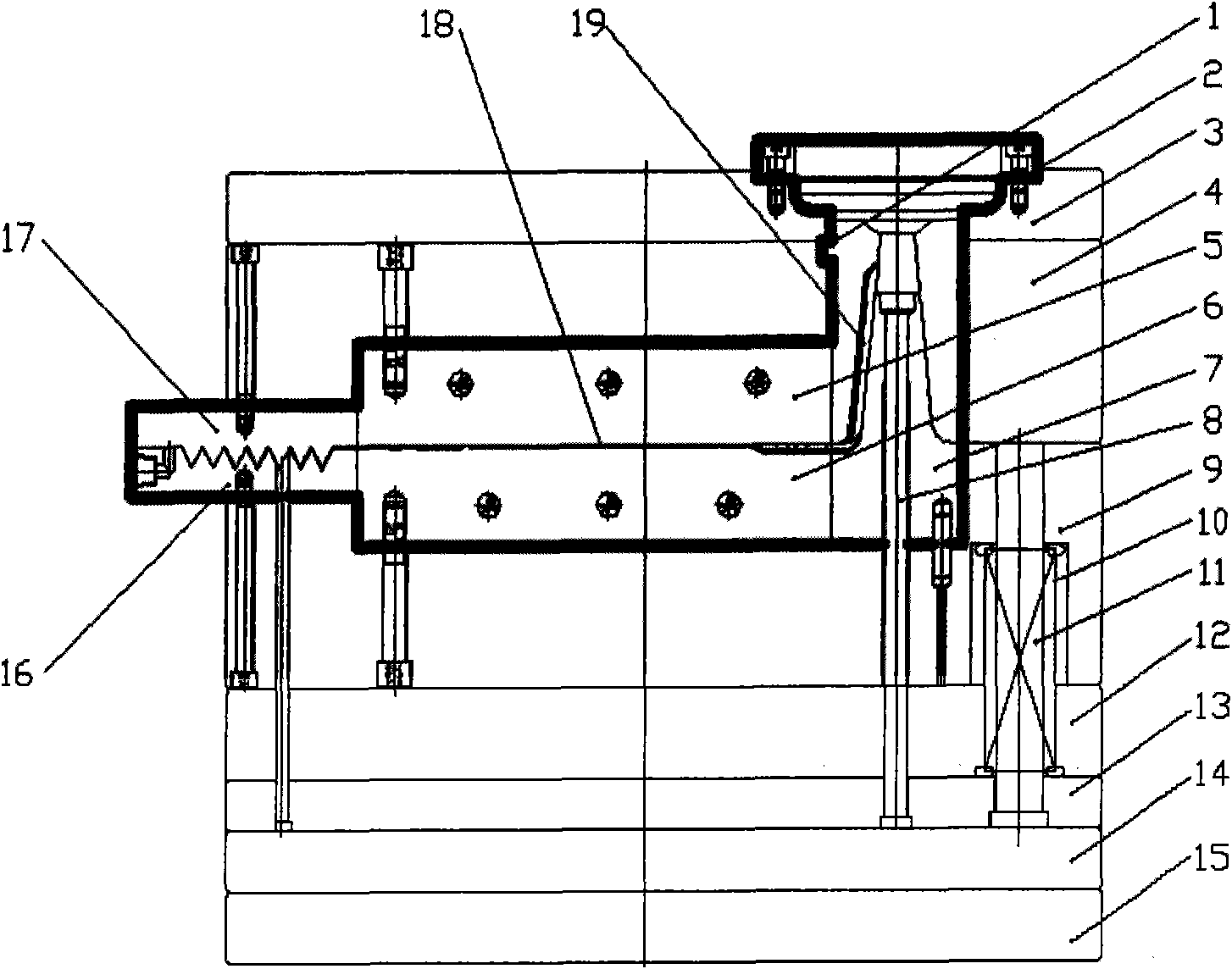

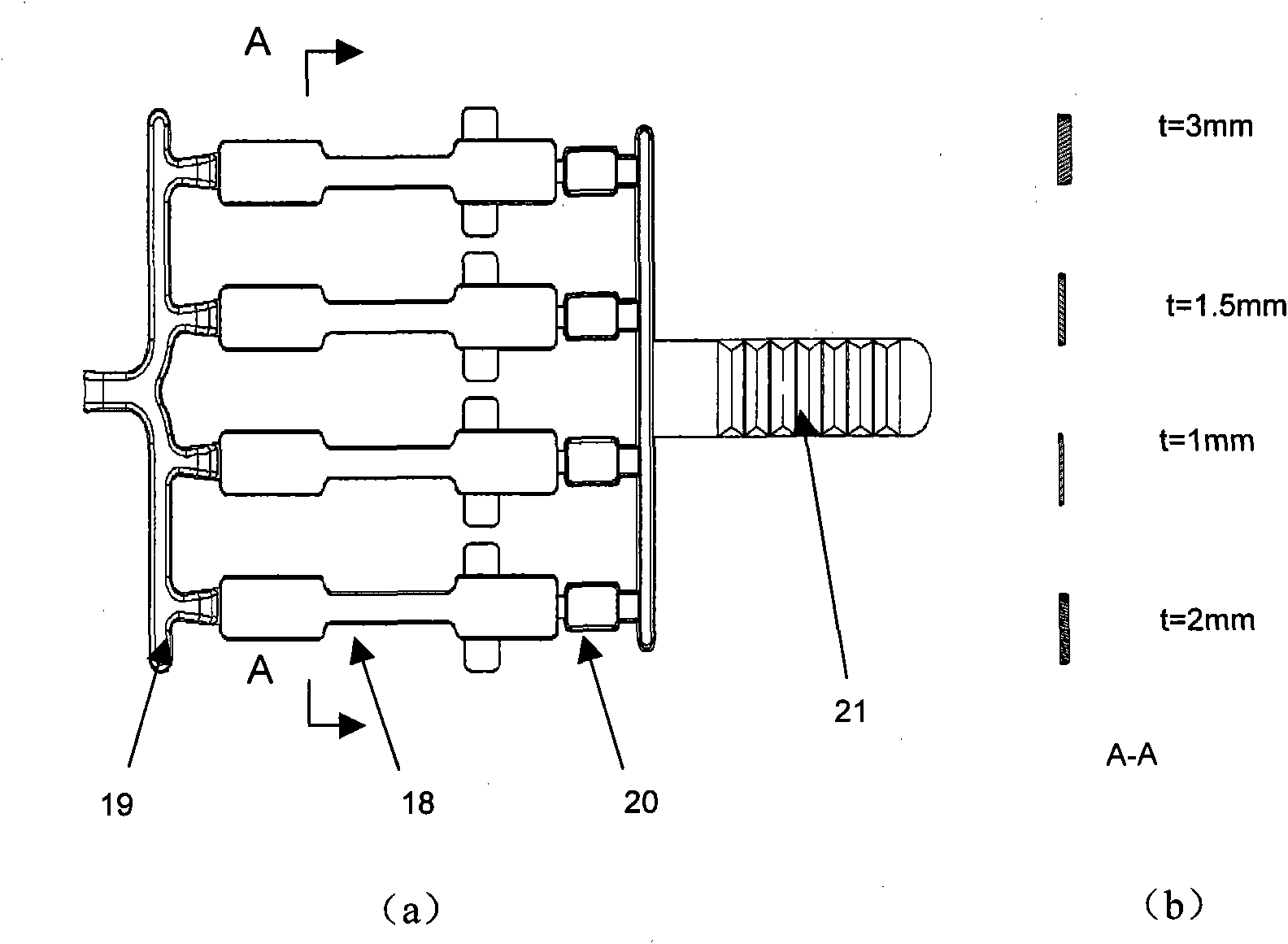

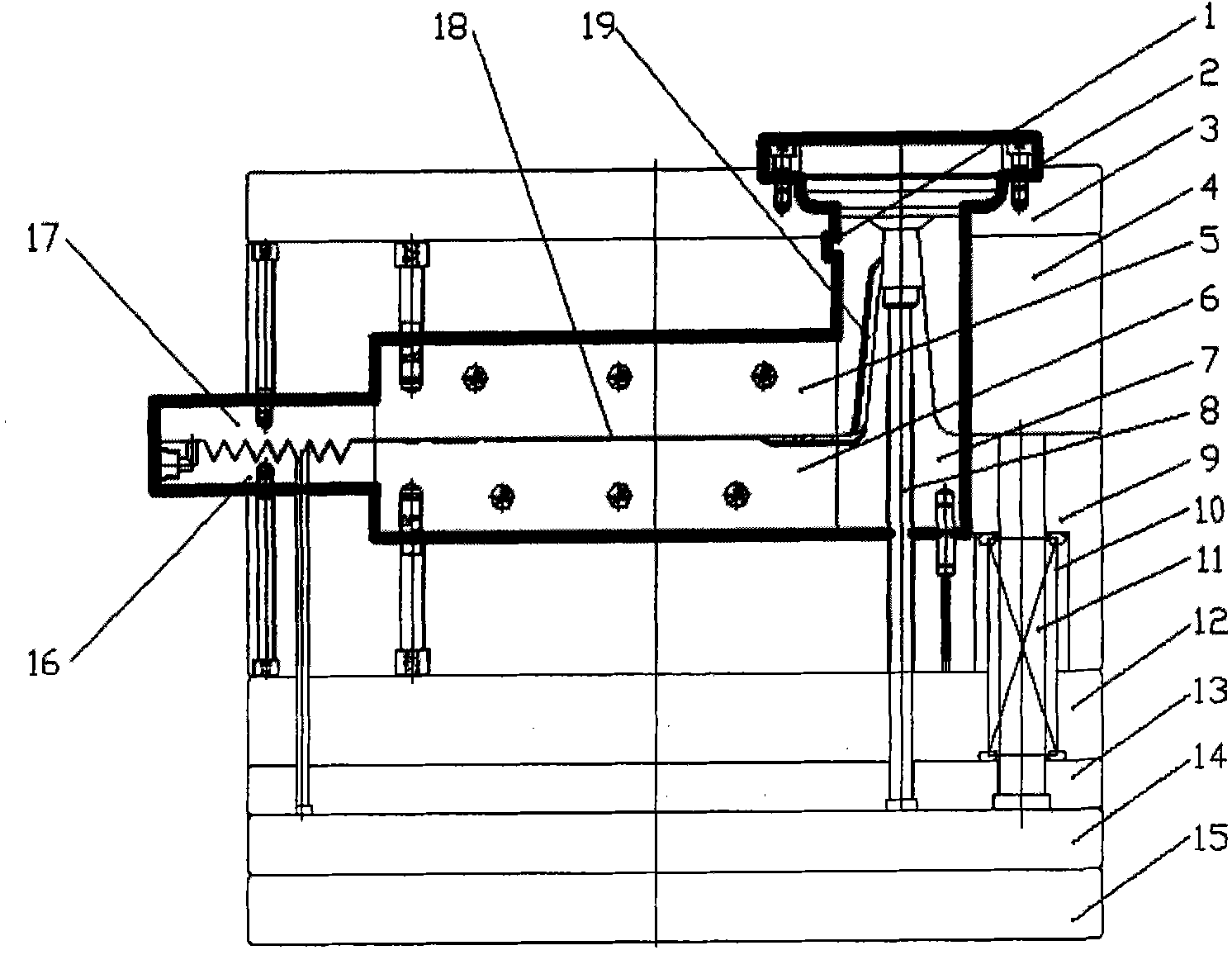

[0021] figure 1It is the mold core of the mechanical performance sample of the patent of the present invention, which is composed of a cavity mold core embedded in a semi-solid injection molding machine and a mechanical performance sample. The cavity mold core of the magnesium alloy mechanical properties is designed as four barbell-shaped mechanical property sample slices with thicknesses of 1, 1.5, 2 and 3 mm respectively, which are respectively connected with the inlet flow channel and the four-point flow channel, and then passed through the slag-shaped Cavity 20, diverges and rejoins, and finally communicates with the cavity 21 of the vacuum exhaust sheet. The mechanical performance sample mold core is composed of sprue sleeve 1, positioning ring 2, splitter cone 7, runner 19, female mold core 5, male mold core 6, cavity 18, ejector pin 8, male mold vacuum inlet 16, The master mold is vacuum-pumped into 17 and other components. Sprue sleeve 1, positioning ring 2, diverter...

Embodiment 2

[0026] In the preparation method for measuring the mechanical properties of magnesium alloy semi-solid injection molding provided by the present invention, the semi-solid magnesium alloy liquid is injected into the mold by using the JLM220 type magnesium alloy semi-solid injection molding machine of JSW Company of Japan. The process parameters during operation are as follows:

[0027] The set temperature of the mold heater: 200°C for the movable mold and 200°C for the fixed mold.

[0028] Release agent: use Acheson CP503, dilution ratio: 1:60.

[0029] Parameter setting of the molding machine: the heating temperature of the barrel is 600°C, the injection speed of the first stage is set to 55%, and the injection speed of the second stage is set to 22%. When injecting the magnesium alloy liquid, do not draw a vacuum.

[0030] Magnesium alloy crumbs: AZ91D crumbs (diameter about ф1-2mm, length about 3-5mm) produced for Nanjing Huahong New Material Co., Ltd. were injected into t...

Embodiment 3

[0034] In the preparation method for measuring the mechanical properties of magnesium alloy semi-solid injection molding provided by the present invention, the Japanese JSWJLM220 type magnesium alloy semi-solid injection molding machine is used to evacuate the inner mold cavity of the sample before injecting the magnesium alloy liquid. , and then inject the semi-solid magnesium alloy liquid into the mould. The process parameters of the operation are as follows:

[0035] The set temperature of the mold heater: 200°C for the movable mold and 200°C for the fixed mold.

[0036] Release agent: use Acheson CP503, dilution ratio: 1:60.

[0037] Molding machine parameter setting: the heating temperature of the barrel is 600°C, the injection speed of the first stage is set to 55%, and the injection speed of the second stage is set to 22%.

[0038] Magnesium alloy crumbs: AZ91D crumbs (diameter about ф1-2mm, length about 3-5mm) produced by Nanjing Huahong New Material Co., Ltd., three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com