Closed-section profiled steel sheet-concrete combined floor and construction method thereof

A technology of profiled steel plate and combined floor slab, applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of large consumption of construction materials, poor mechanical performance, etc., to reduce construction costs, ensure project quality, and meet structural load bearing requirements The effect of force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

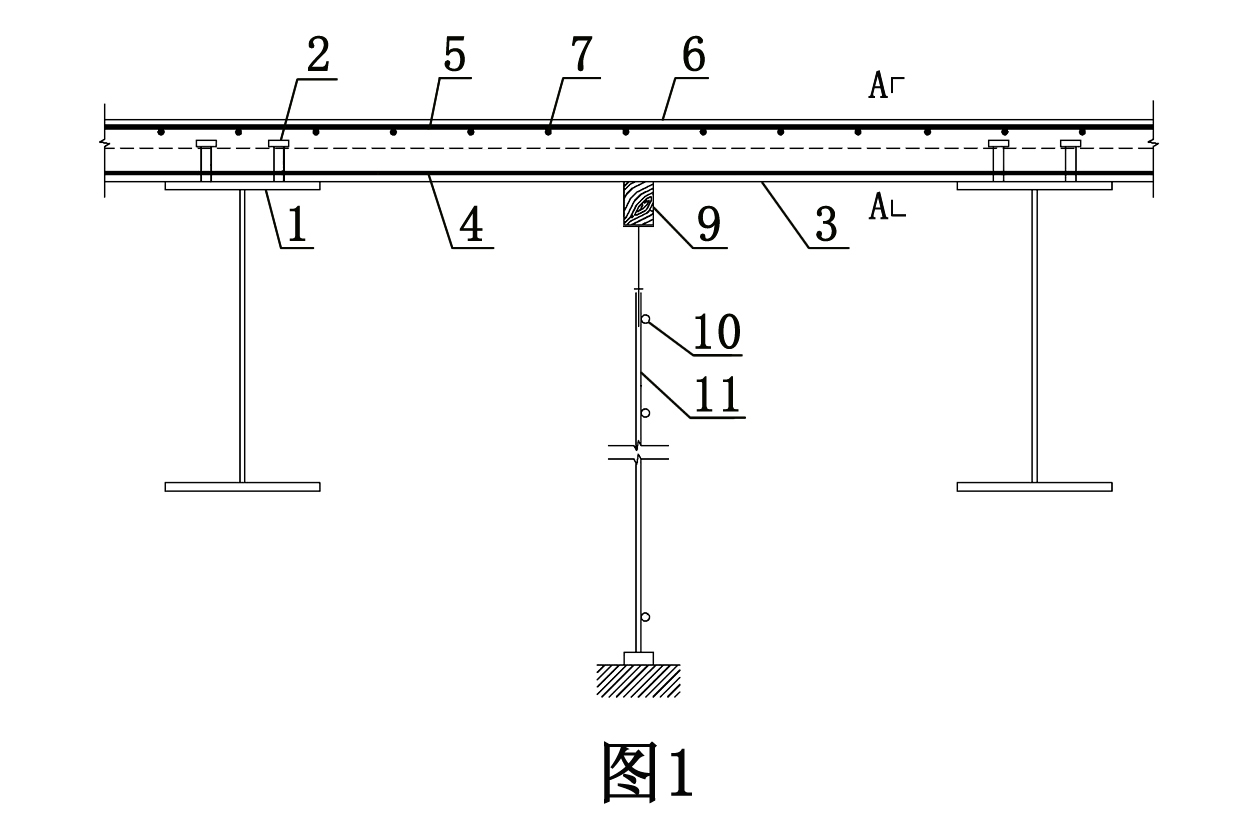

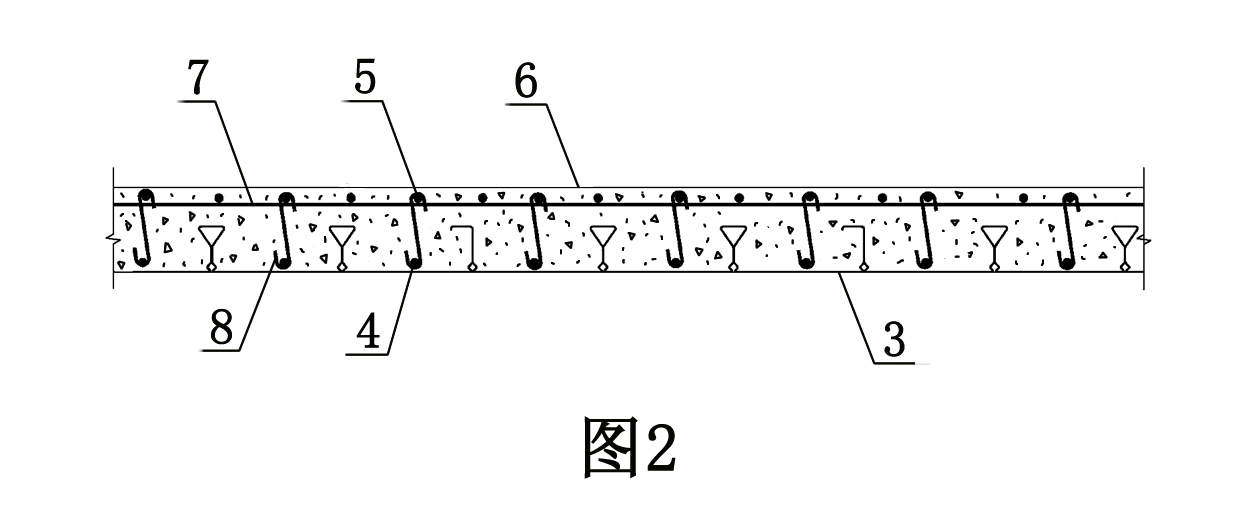

[0024] Examples see figure 1 , figure 2 As shown, this closed profiled steel plate-concrete composite floor includes a closed profiled steel plate 3 and concrete 6 poured on the closed profiled steel plate, and the closed profiled steel plate 3 is laid on the steel structure main body On the steel beam 1, the bottom of the closed profiled steel plate 3 is fixedly connected with the steel beam 1 by the stud 2, and the bottom of the closed profiled steel plate 3 between the steel beams is erected with a top brace, and each of the closed profiled steel plate 3 A lower iron stress rib 4 is arranged in the wave groove 3.3, and an upper iron stress rib 5 is correspondingly arranged above each lower iron stress rib 4, between the lower iron stress rib 4 and the upper iron stress rib 5 Connected by the tie bars 8, the upper iron stress bars 5 are set up on the upper iron distribution bars 7, and the two are set up into a well-shaped shape.

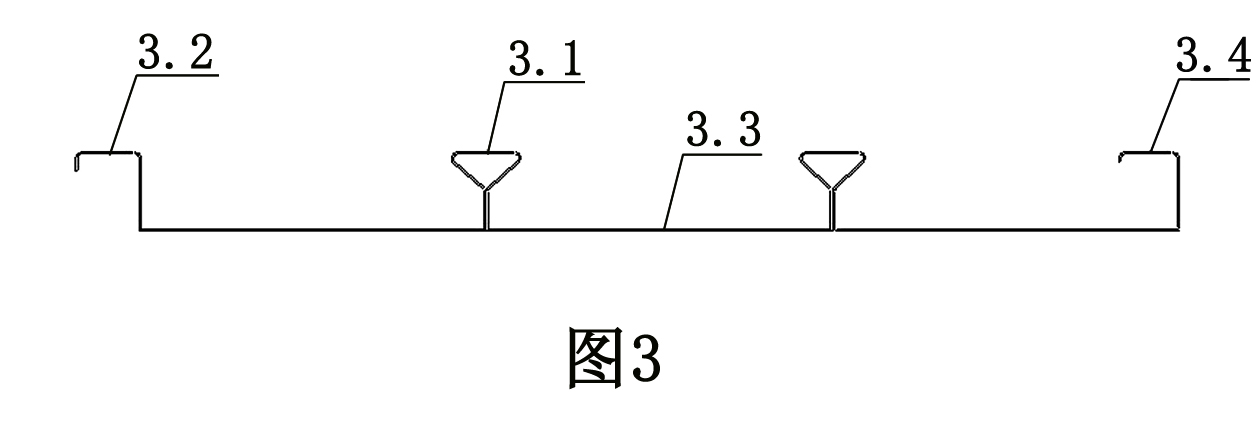

[0025] see image 3 As shown, the close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com