Hydrogenation system for producing hydrogen peroxide

A hydrogenation system, hydrogen peroxide technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of short regeneration cycle, accelerated Catalyst aging, complicated pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

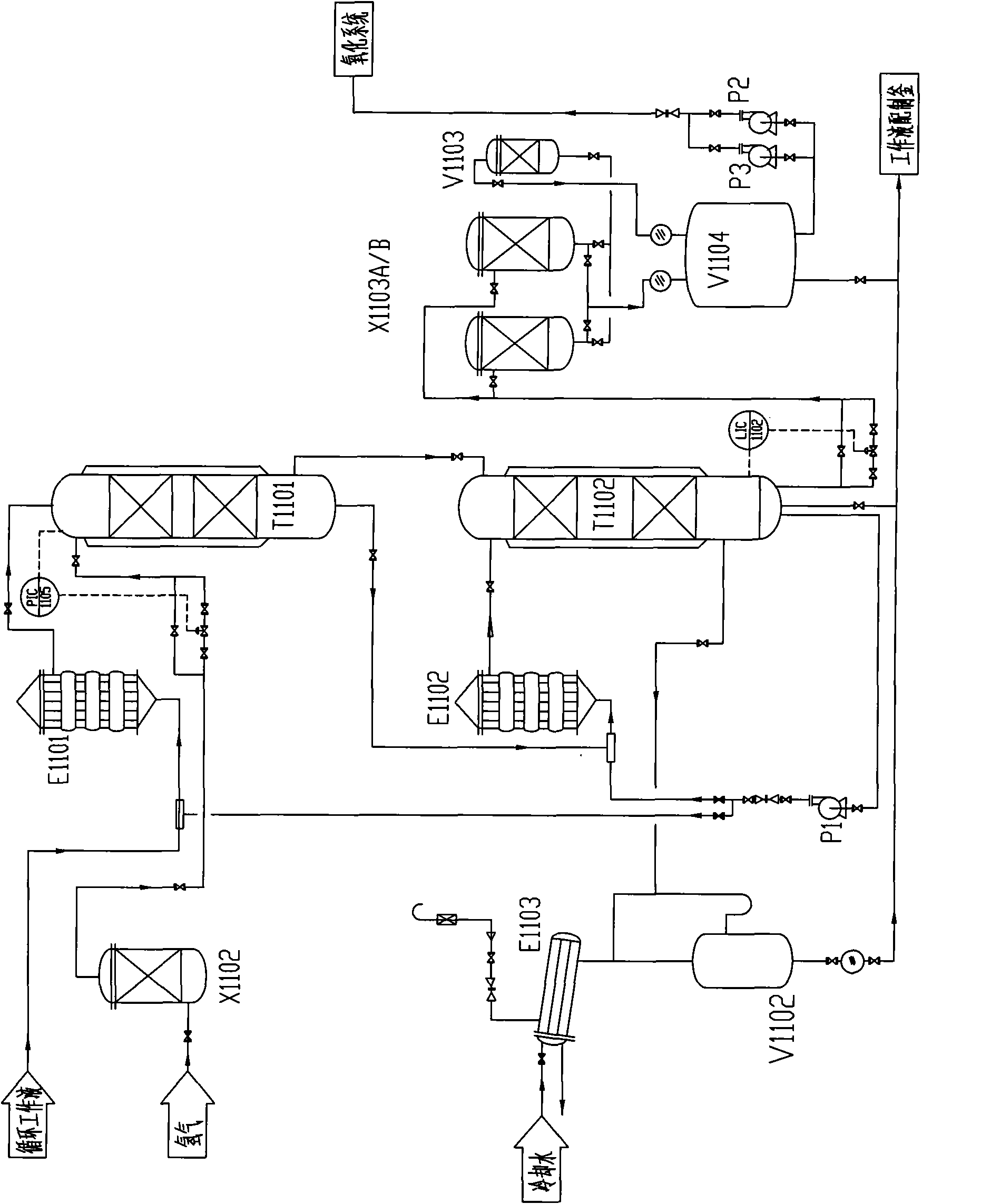

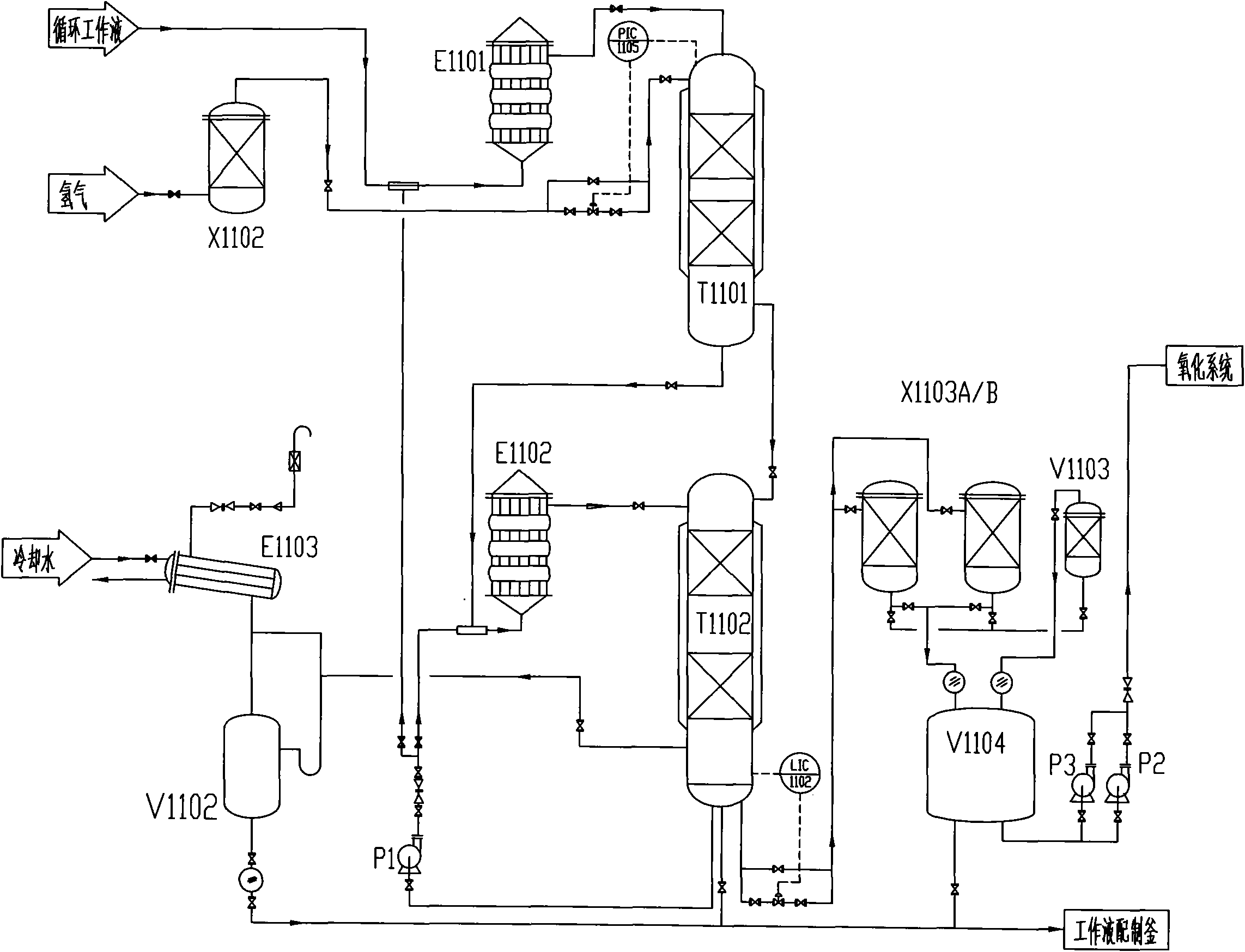

[0011]As shown in the figure, it is a working principle diagram of a hydrogenation system for hydrogen peroxide production. The hydrogenation system mainly includes a hydrogen filter X1102, a working fluid preheater E1101, a hydrogenation tower, a hydrogenation liquid gas-liquid separator, Hydrogenation liquid filter X1103A / B, hydrogenation liquid regeneration bed V1103, hydrogenation liquid storage tank V1104; the inlet of the hydrogen gas filter X1102 is connected to the hydrogen gas source, the outlet of the hydrogen gas filter X1102 is connected to the hydrogen gas inlet of the hydrogenation tower, and the working fluid is preheated The inlet of the device E1101 is connected to the source of the working fluid, the outlet of the working fluid preheater E1101 is connected to the inlet of the working fluid of the hydrogenation tower, the hydrogenation liquid outlet at the bottom of the hydrogenation tower is connected to the hydrogenation liquid gas-liquid separator, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com