Transfer device and transfer method for printed sheets of paper

A technology of printing paper and transfer printing, which is applied to the transfer printing device and the field of transfer printing on printing paper, and can solve the problems of affecting printing quality and incapable of high-precision transfer film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

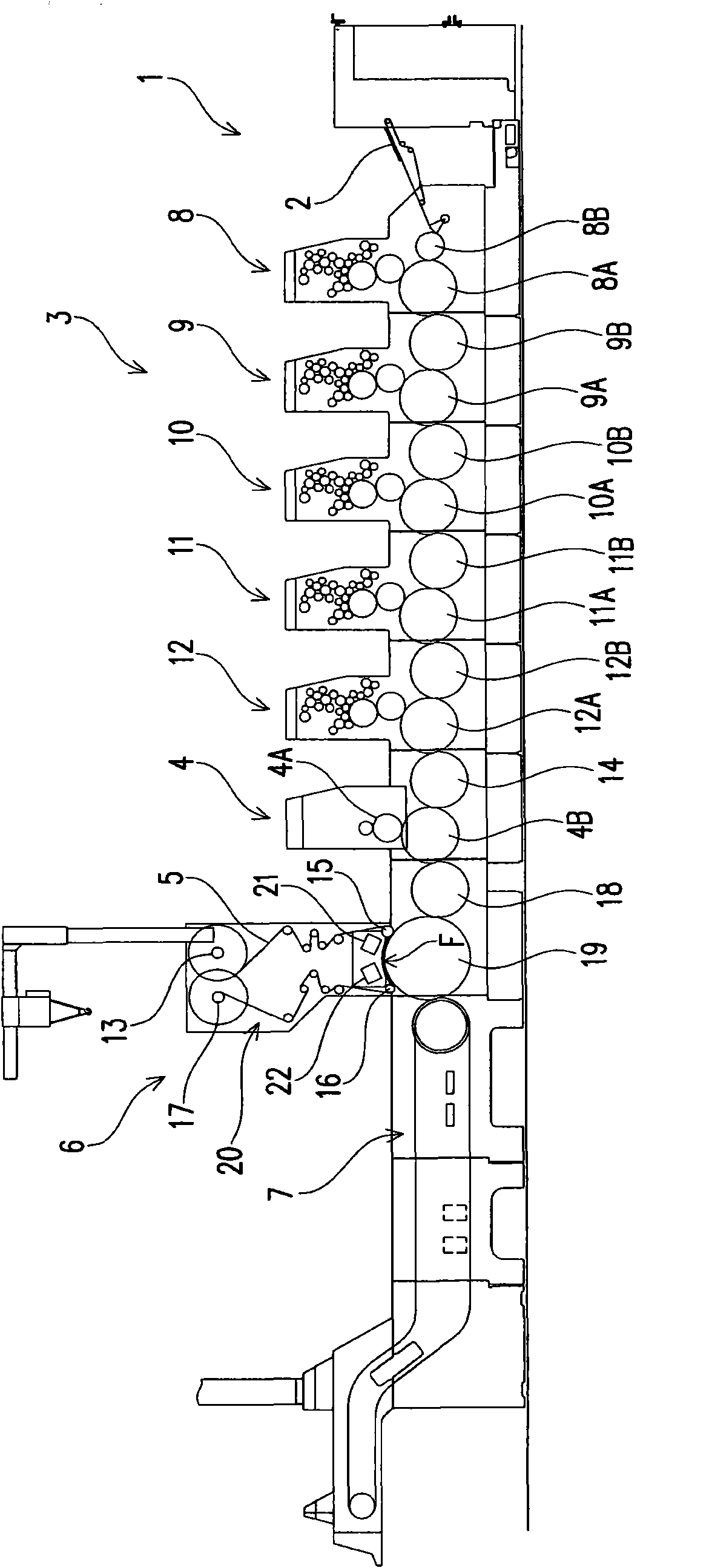

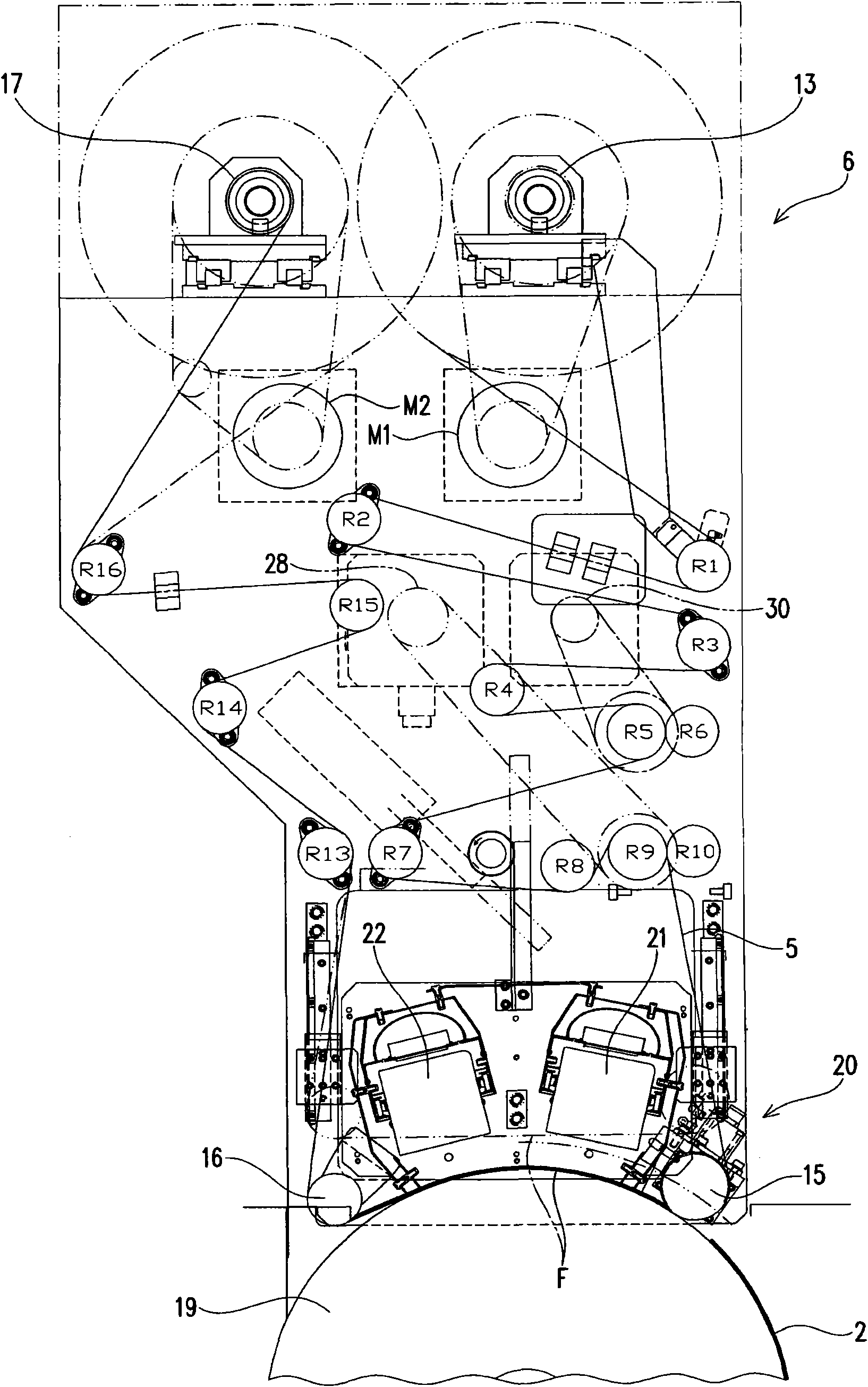

[0021] figure 1 Shown is an example of a printing machine incorporating a transfer device 6 that can be made glossy by applying a resin varnish to the printing surface of printing paper, and then further transferring gold foil, embossing Patterns or holographic patterns, etc., to process the printing surface of the printing paper. The printing machine includes: a paper feeding unit 1, which is used to send out printing paper 2 from the stacker one by one through a paper feeding device or a paper separation device, etc.; Five-color printing; the varnish coating part 4, coating (coating) ultraviolet curable resin varnish on the printing paper 2 printed by the printing part 3; The UV-curable resin varnish on the printing paper 2 coated with UV-curable resin varnish is pressed with a material (for example, polyethylene terephthalate, so-called PET and other materials) that has the ability to restore. A transfer film 5 for surface-processing the printing paper 2 ; and a paper dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com