Pipe degreasing equipment based on ultrasonic cleaning technology and using method thereof

An ultrasonic and pipe technology, applied in the field of pipe degreasing equipment based on ultrasonic cleaning technology, can solve the problems of unsuitable pipes with long lengths, time-consuming and laborious, complicated auxiliary equipment, etc., to improve the degreasing effect, the device structure is simple, and the cost is low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

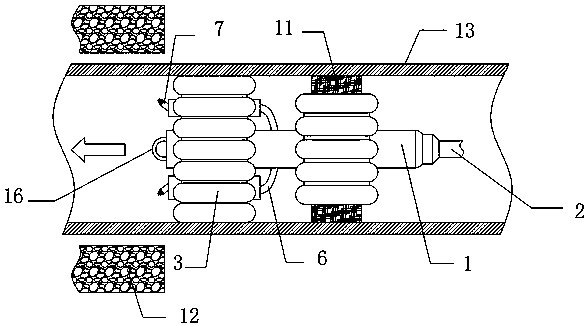

[0047] see Figure 1-7 , a pipe degreasing equipment based on ultrasonic cleaning technology, see figure 2 , including the moving pipe 1 and the pipe 13, the side wall of the end of the moving pipe 1 away from the water pipe 2 is fixedly connected with a hook 16, when the inside of the pipe 13 is not smooth enough and the friction resistance is large or the pipe is not magnetic, it can be tied on the hook 16 Pull the rope to add additional auxiliary pulling force to counteract the frictional force, but ensure that the moving speed of the pulling rope is the same as that of the cart. One end of the moving pipe 1 is connected to the water pipe 2. The water pipe 2 is made of soft material, and the water pipe 2 is far away from the One end of the moving tube 1 is connected with degreasing agent delivery equipment, and an ultrasonic generator is installed in the degreasing agent delivery equipment, and the ultrasonic generator emits ultrasonic waves in the degreasing agent deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com