Preparation method of instant fresh water fish peptide powder

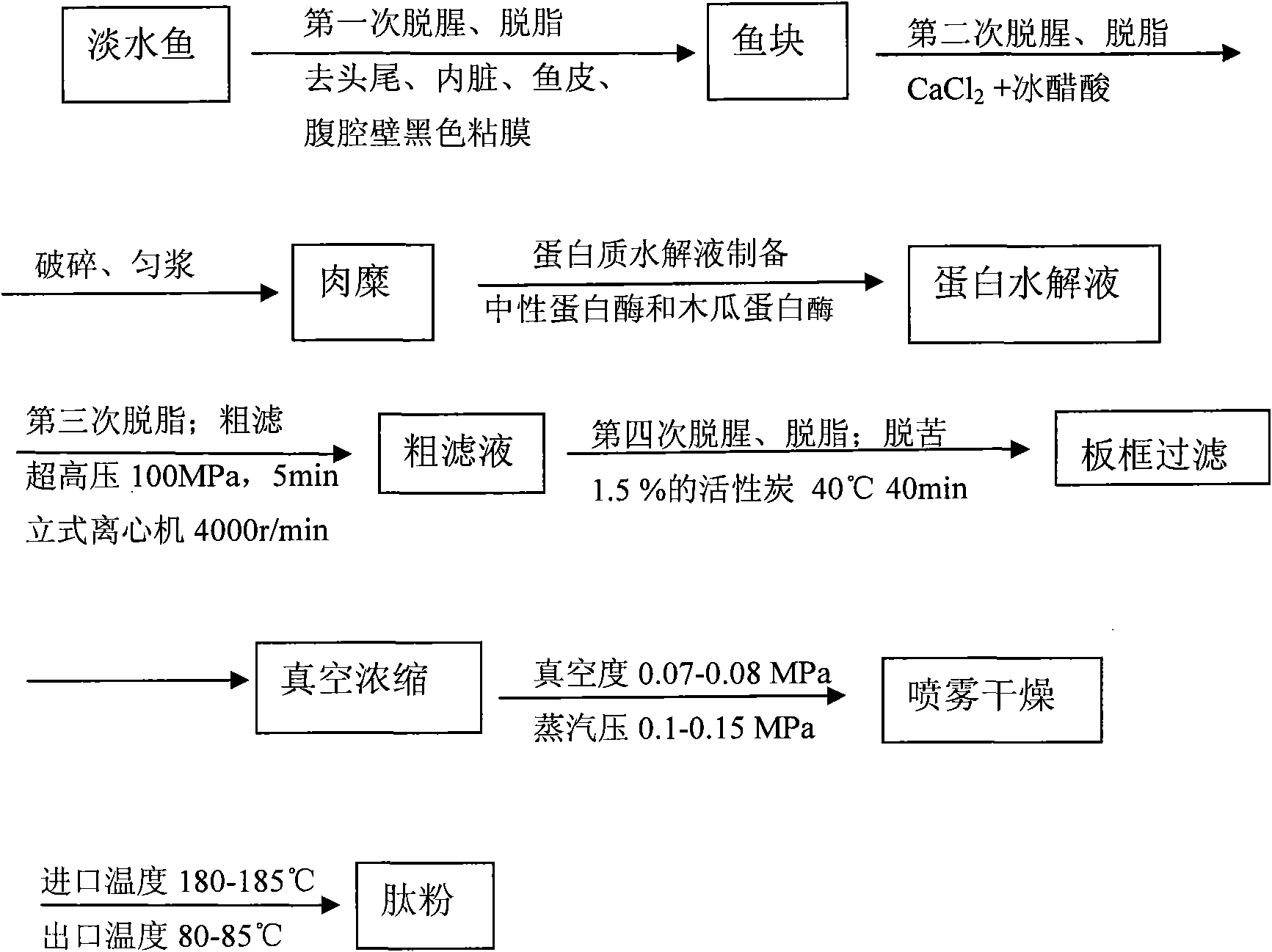

A technology for freshwater fish and its production method, which is applied in protein food processing, animal protein processing, food science, etc. It can solve problems such as difficult deodorization, debitterness, and incomplete hydrolysis of fish protein, and achieve easy absorption, milky white color, and amino acid The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Choose fresh and live freshwater fish (such as crucian carp), take 5000g of live fish, cut off its head, tail, viscera and abdominal black membrane, and clean it; use a peeling machine to remove the fish skin, and then use a cutter to cut the fish into about 40g fish pieces; soak the cleaned fish pieces in a degreasing solution that is 2.5 times the mass of the fish meat, and the degreasing solution is 0.1% CaCl 2 The mixture of +0.1% glacial acetic acid was stirred continuously for 60min, and rinsed until neutral; the fish pieces were mashed with a masher to make 1930g surimi, and an appropriate amount of water (about 3000g) was added; at a temperature of 55°C and a pH of 7. Under the condition of 0, add 0.1% Bacillus subtilis neutral protease to the surimi to hydrolyze it for 1.5h, inactivate the enzyme at 80°C for 5min; then add 1.5% papain to the hydrolyzate and hydrolyze for 2.5h; take the hydrolyzate High temperature and high pressure to inactivate the enzyme for ...

Embodiment 2

[0033] The main steps used are the same as in Example 1, but the amount of neutral protease added is 0.05%, the enzymolysis time is 2 hours, papain is 2.0%, and after 2 hours of hydrolysis, the enzyme is inactivated to complete the hydrolysis reaction.

Embodiment 3

[0035] The main steps used are the same as in Example 1, but the addition of neutral protease is 0.15%, the enzymolysis time is 1h, papain is 1.0%, and after 3h of hydrolysis, the enzyme is inactivated to end the hydrolysis reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com