Lithium battery management system

A management system, lithium battery technology, applied in lithium batteries, secondary batteries, battery circuit devices, etc., can solve the problems of hidden dangers, poor reliability, high cost, and achieve safe work, strong anti-interference ability, and enhanced reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Some modules of the lithium battery management system will be further described below in conjunction with the accompanying drawings.

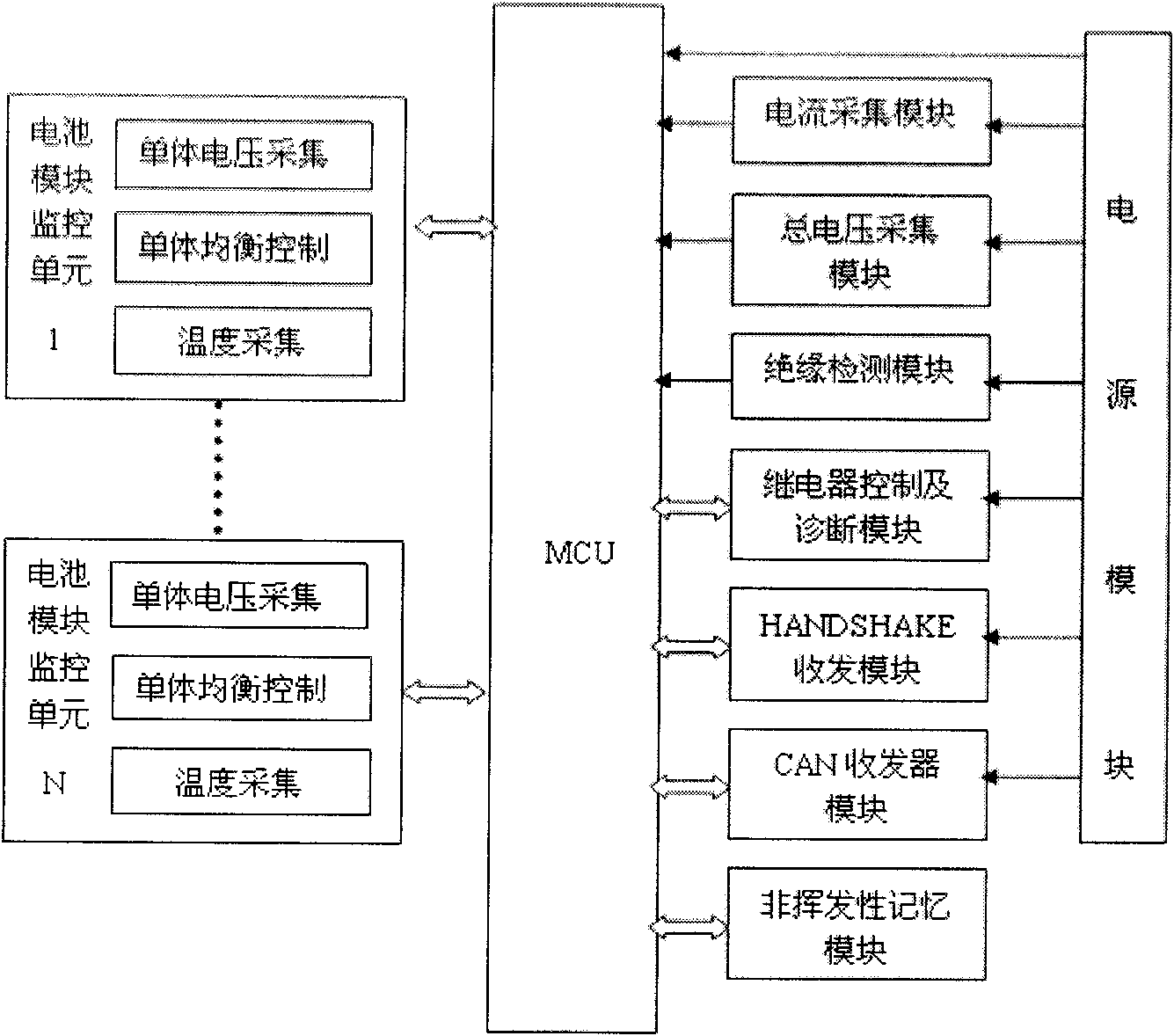

[0029] figure 1 It is a block diagram of the overall structure of the lithium battery management system. The lithium battery management system includes: MCU (microprocessing) module, power module, total voltage acquisition module, current acquisition module, insulation detection module, relay control and diagnosis module, HANDSHAKE (handshake signal) transceiver module, CAN transceiver module, Volatile memory modules and battery module monitoring units 1, 2...N.

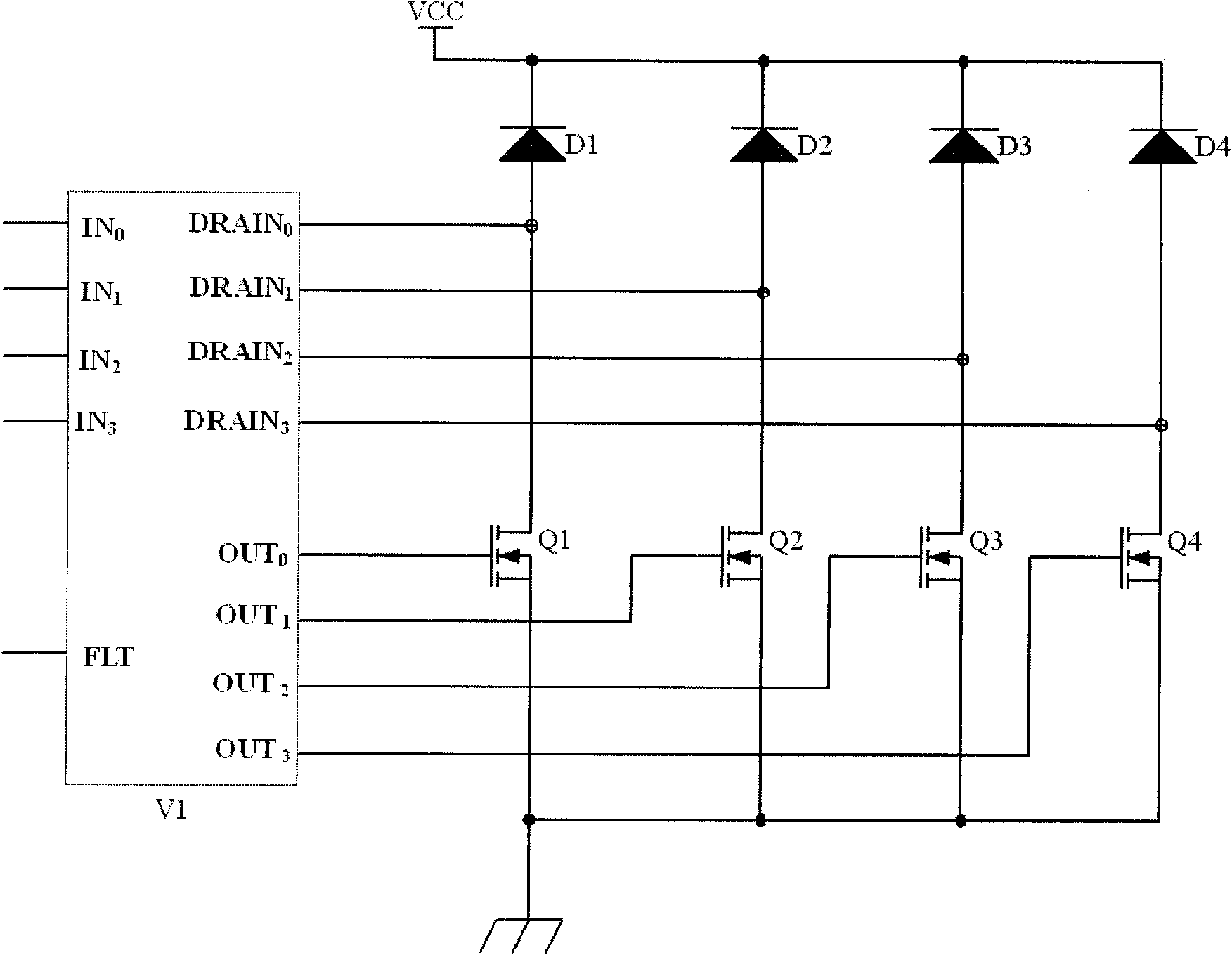

[0030] figure 2 It is a schematic diagram of the relay control and diagnosis module. The module receives the control signal from the MCU I / O port through the input terminals IN0, IN1, IN2, and IN3 of the FET pre-driver chip V1, and the FET pre-driver chip V1 outputs OUT0 and OUT1 , OUT2, OUT3 are respectively connected to the gates of field effect transistors Q1, Q2, Q3, Q4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com