Method and device for testing tensile strength of axial lead of glass shell diode

An axial lead and tensile strength technology, which is used in the application of stable tension/compression to test the strength of materials and single semiconductor device testing. or easy removal, ensure test accuracy, and easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

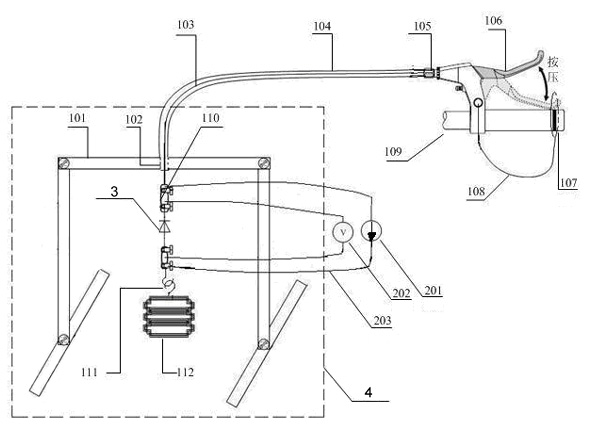

[0026] The specific implementation manner of the present invention will now be described in conjunction with the accompanying drawings.

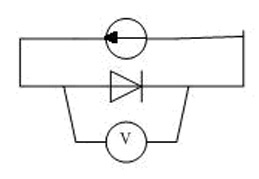

[0027] Aiming at the special requirements of the tensile strength test of the axial lead of the glass shell diode, the invention proposes a test device for the tensile strength of the axial lead of the glass shell diode. It includes an axial lead tension application system, a forward voltage measurement system, and a hot air source system. A method for testing the tensile force resistance of an axially leaded glass bulb diode comprises three steps of test preparation, test execution, and test completion.

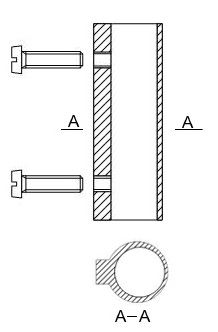

[0028] The schematic diagram of the test device is shown in the figure. The axial lead tension application system, the forward voltage measurement system, and the hot air source are connected to realize the test of the tensile resistance of the axial lead of the glass shell diode. The axial lead tension application system includes a tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com