Connecting structural component for air-separation cold box and method for integrally assembling cold box

A technology of connecting structure and cold box, which is applied in the connection of connecting members, rods, refrigeration and liquefaction, etc., can solve the problem of tall tower body of fractionation tower, and achieve the effect of satisfying quality requirements, simple structure and preventing tower body dislocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

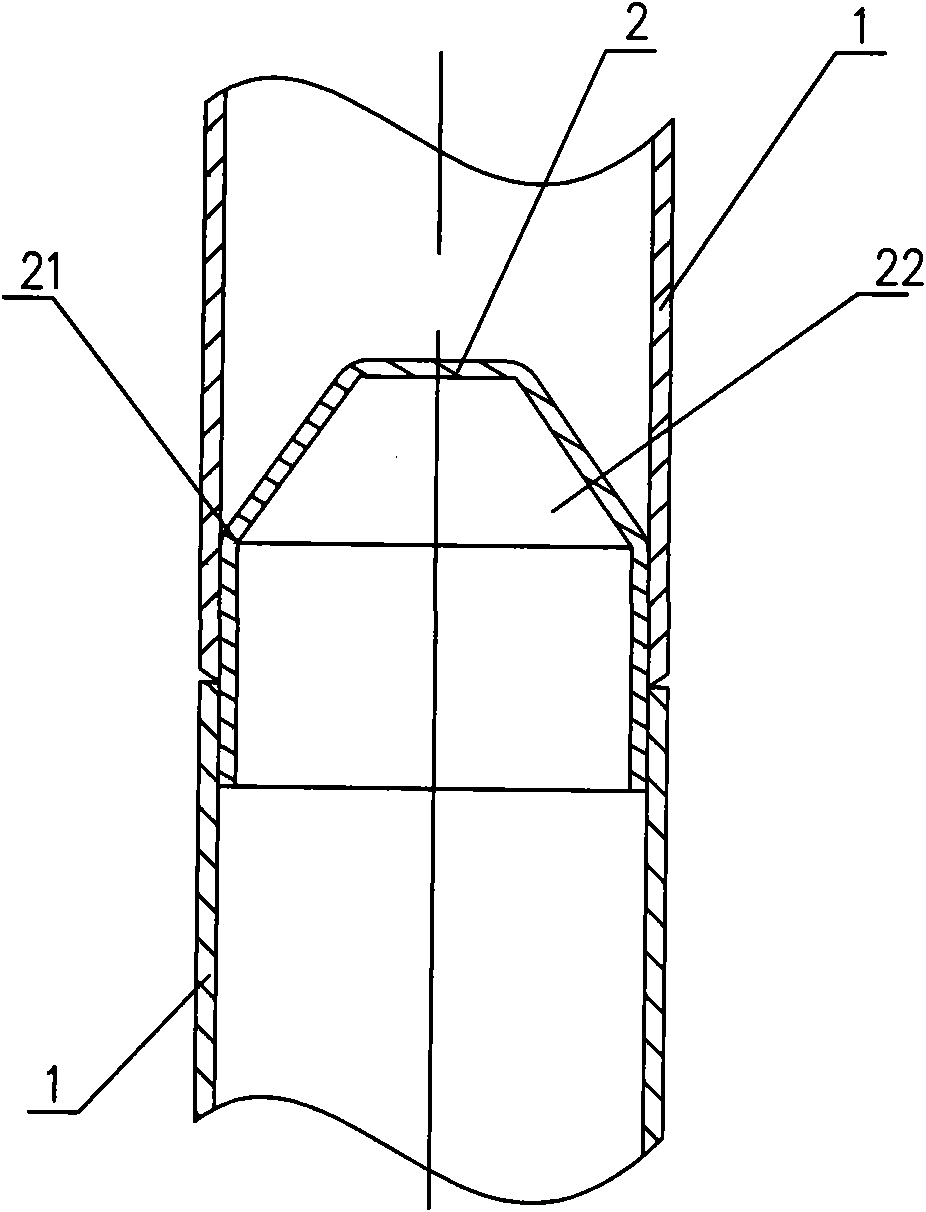

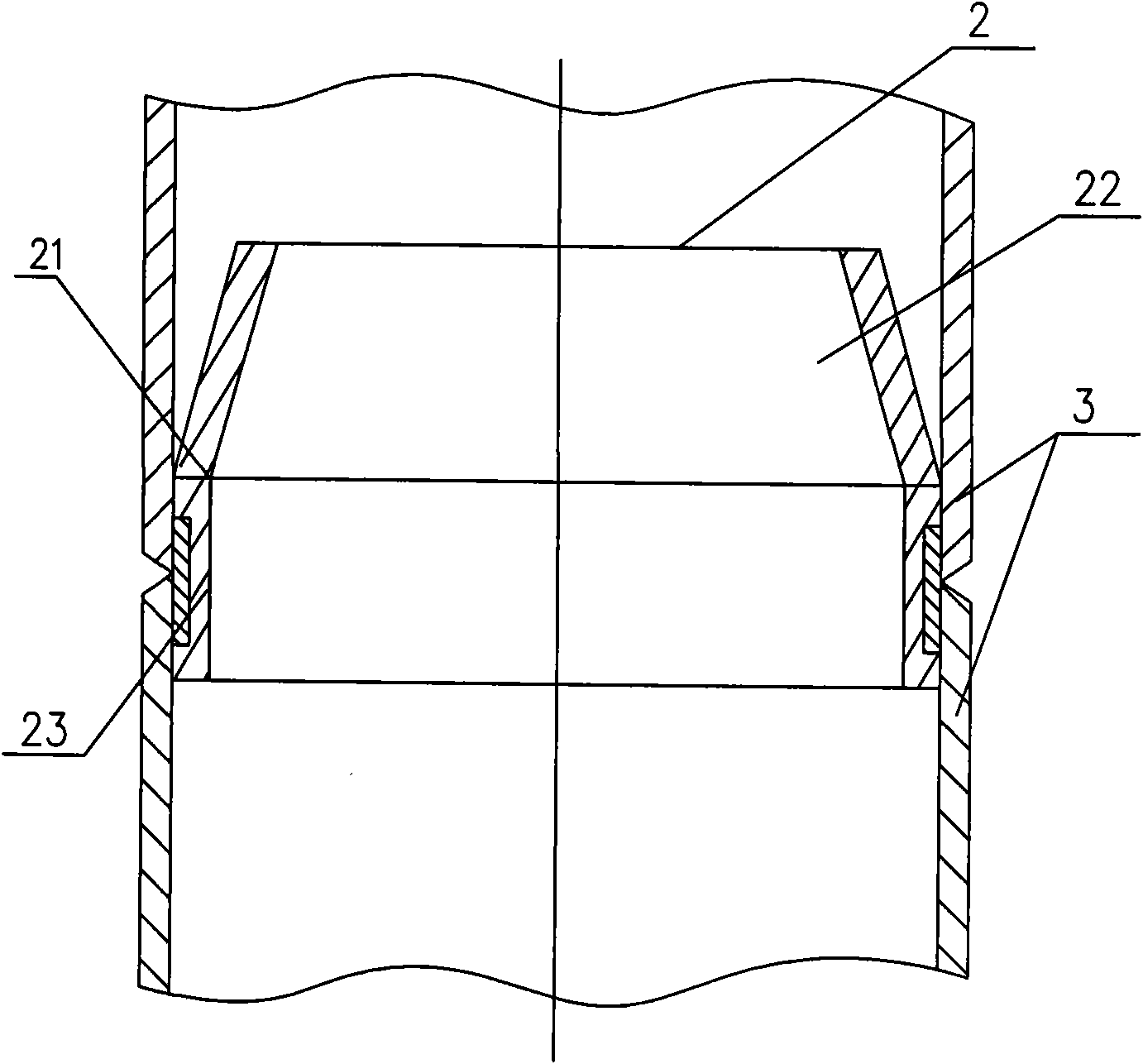

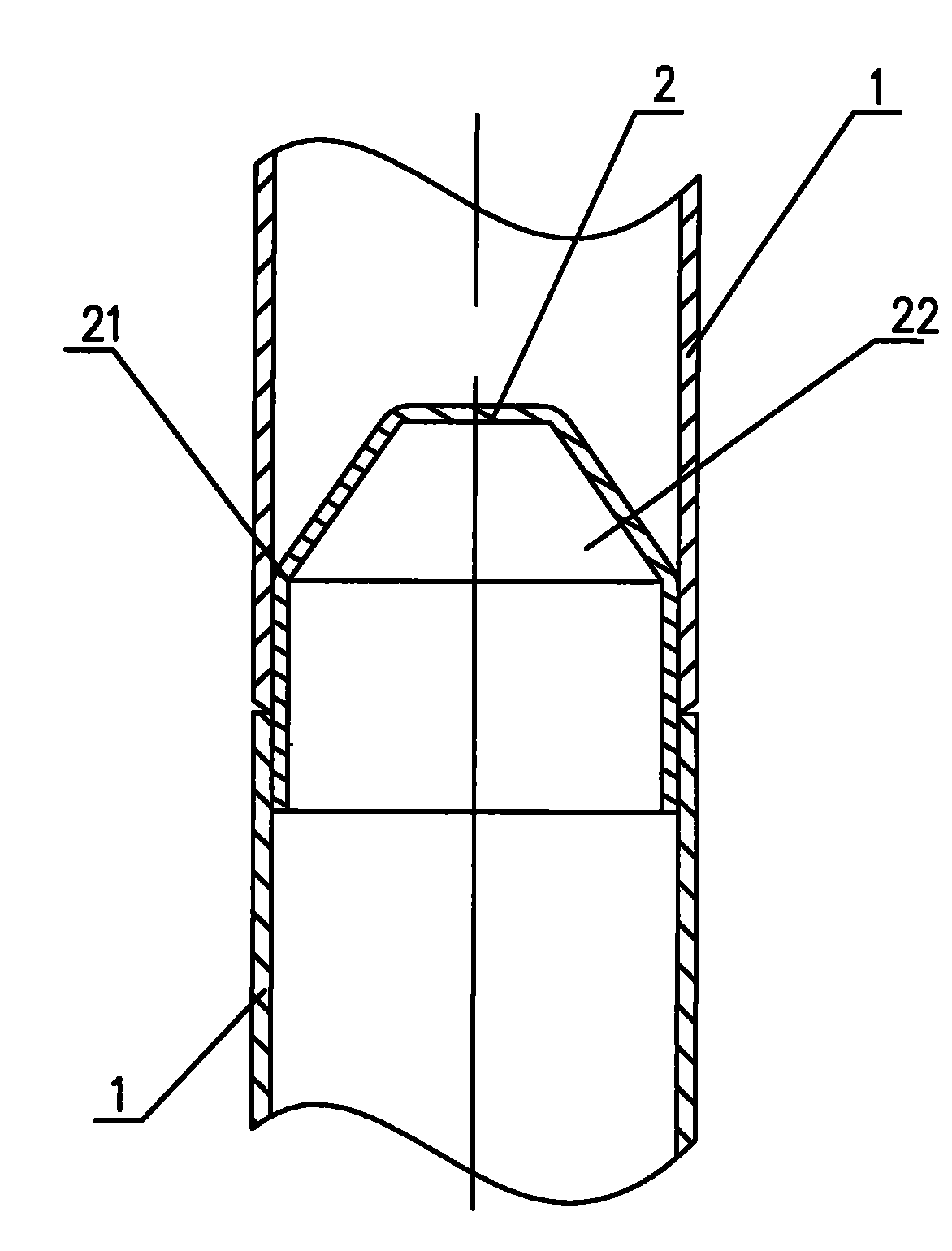

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 Shown, the connection structure of the air separation cold box of the present invention, it comprises a guiding connecting body 2 that can be installed in the skeleton steel pipe 1 joint that forms through up and down in the cold box, described guiding connecting body 2 is formed by At least one section is fixed on the inner wall of one of the joint ends of the steel pipes 1 to serve as an inner cylinder 21 for butt guiding and a cone 22 connected to the inner cylinder 21. The inner cylinder 21 of the guide connecting body 2 is consistent with the shape of the inner hole of the skeleton steel pipe 1, which is square, circular or polygonal; the cone 22 connected to the inner cylinder 21 is also correspondingly square or circular. Or polygonal and welded or pressed, and the taper angle of the cone is 15 to 30 degrees.

[0014] The method for assembling the cold box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com