Double-layer waterproof and double-layer water exhaust structure of heat insulation house surface and construction method thereof

A drainage structure and waterproof layer technology, which is applied in the direction of roof drainage, roof covering, roof ventilation, etc., can solve the problems that the inverted roof protection layer is easy to crack and leak, water vapor cannot be discharged, and roof leakage, etc. Insufficient effect of the waterproofing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

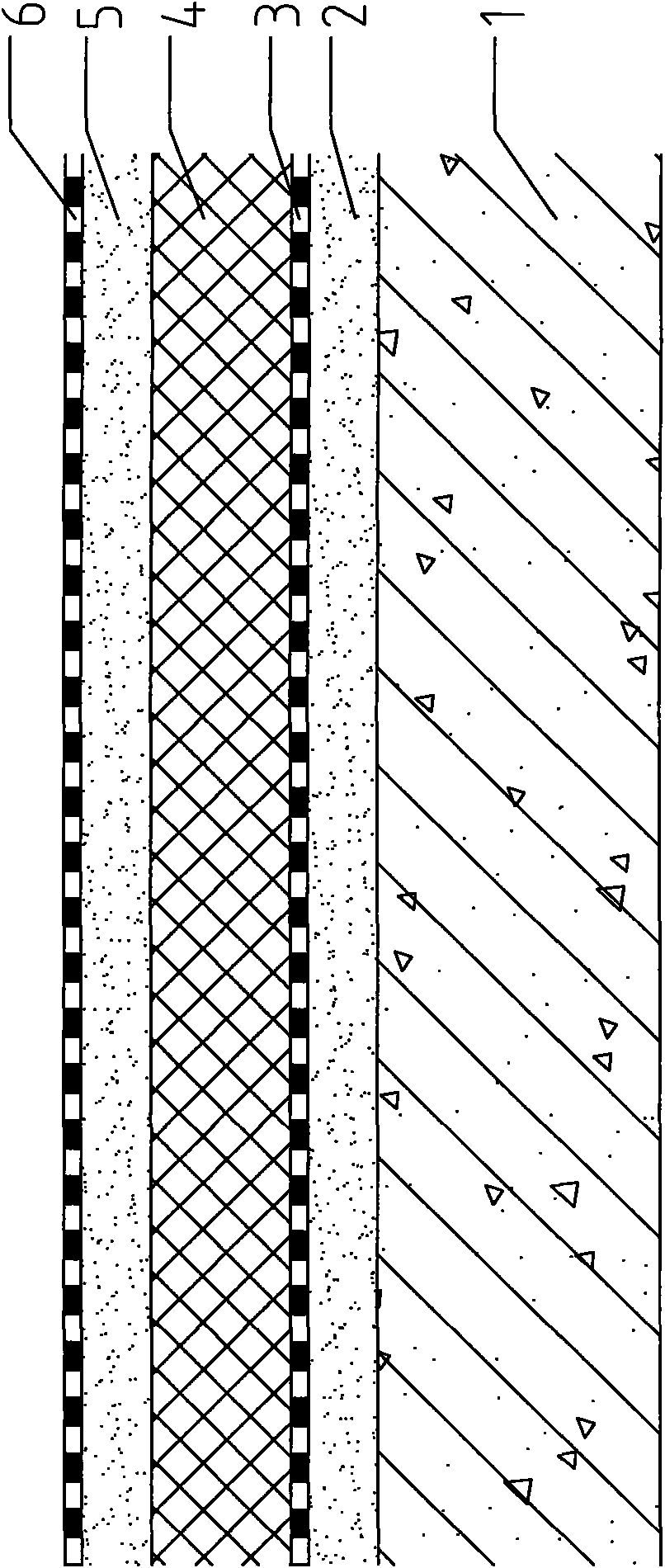

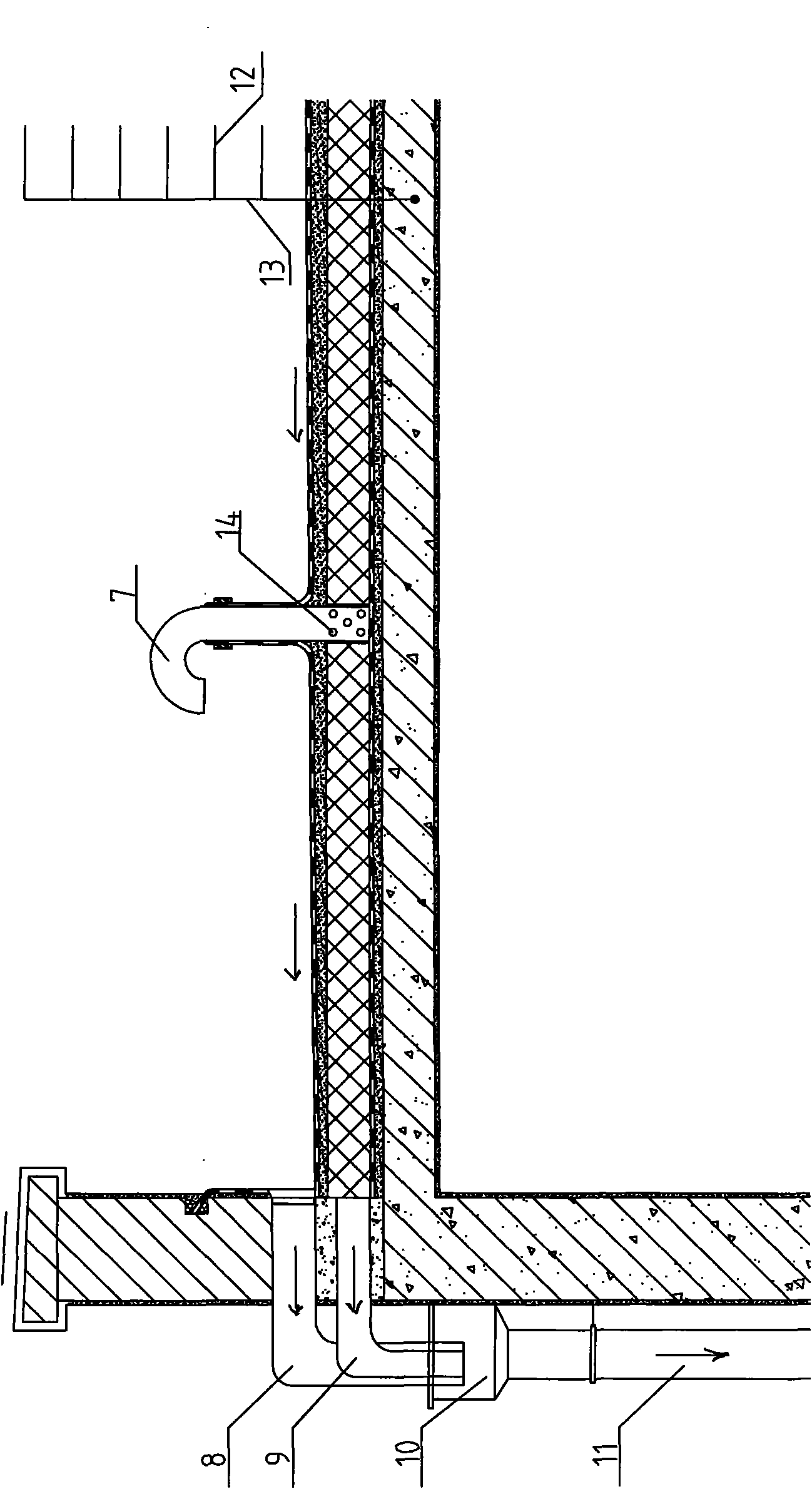

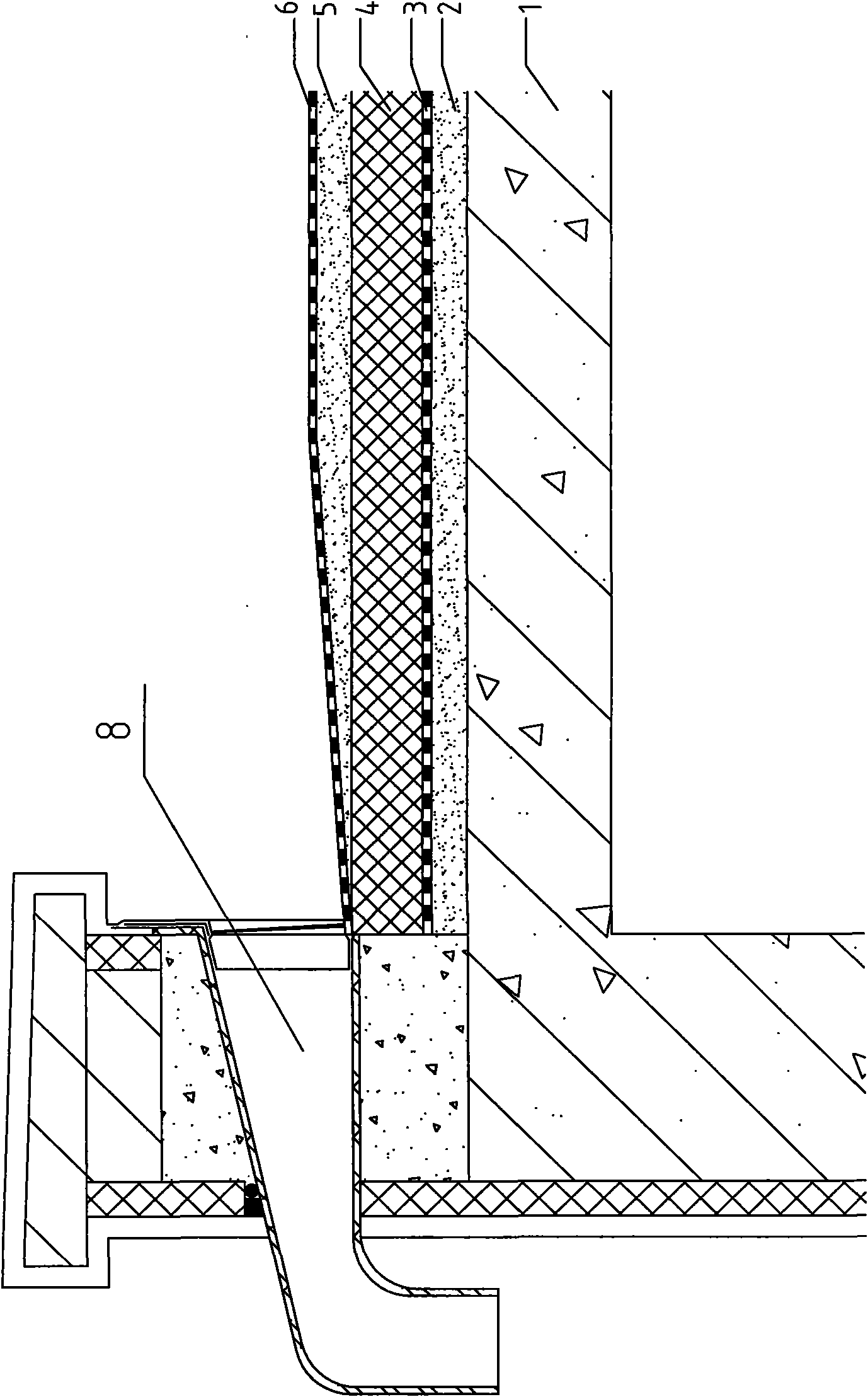

[0021] This embodiment is a double-layer waterproof double-layer drainage structure for heat-insulating roofs, see attached Figure 1-5 , the structure is sequentially provided with a reinforced concrete roof panel 1, a bottom cement mortar leveling layer 2, a bottom waterproof layer 3, an insulation layer 4, a surface cement mortar leveling layer 5, and a surface waterproof layer 6 from bottom to top. There are two sets of drainage systems on the top and bottom of the thermal insulation roof: one is the bottom waterproof drainage system, and the other is the surface layer waterproof drainage system. The drainage system is mainly composed of drainage pipes and sinks. See image 3 A roof drain pipe 8 is arranged on the waterproof layer 6 of the surface layer. See Figure 4 , the bottom waterproof layer 3 is provided with insulation layer drainage pipe 9.

[0022] See figure 1 , Figure 5 One end of the insulation layer drainage pipe 9 used to remove water accumulated in the...

Embodiment 2

[0025] A construction method for a double-layer waterproof double-layer drainage structure on an insulating roof, the construction steps are as follows:

[0026] Set the following layers in turn on the reinforced concrete roof panel 1, firstly plaster the bottom cement mortar leveling layer 2 and find a slope, the downward slope is 3-5 degrees. And according to the design requirements, on the bottom cement mortar leveling layer 2, a plurality of 2-5cm wide and 4-6m horizontal exhaust ditches 12 are opened, and several vertical exhaust ditches 13 are arranged vertically. Design requirements run through. A plurality of roof exhaust outlets communicating with the atmosphere are correspondingly arranged at multiple intersections of the longitudinal and transverse exhaust grooves. Pave the bottom waterproof layer 3 according to the design and construction of organized drainage, extend the bottom waterproof layer out of the roof, then lay the thermal insulation layer 4 on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com