Paper making pulping black liquid crystallization and evaporation method

A technology for pulping black liquor and black liquor in papermaking, which is applied in the direction of concentrating waste liquid and the like, can solve the problem of inability to effectively avoid the scaling of evaporators, and achieves improved utilization efficiency and economic benefits, increased steam production, and improved thenardite reduction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

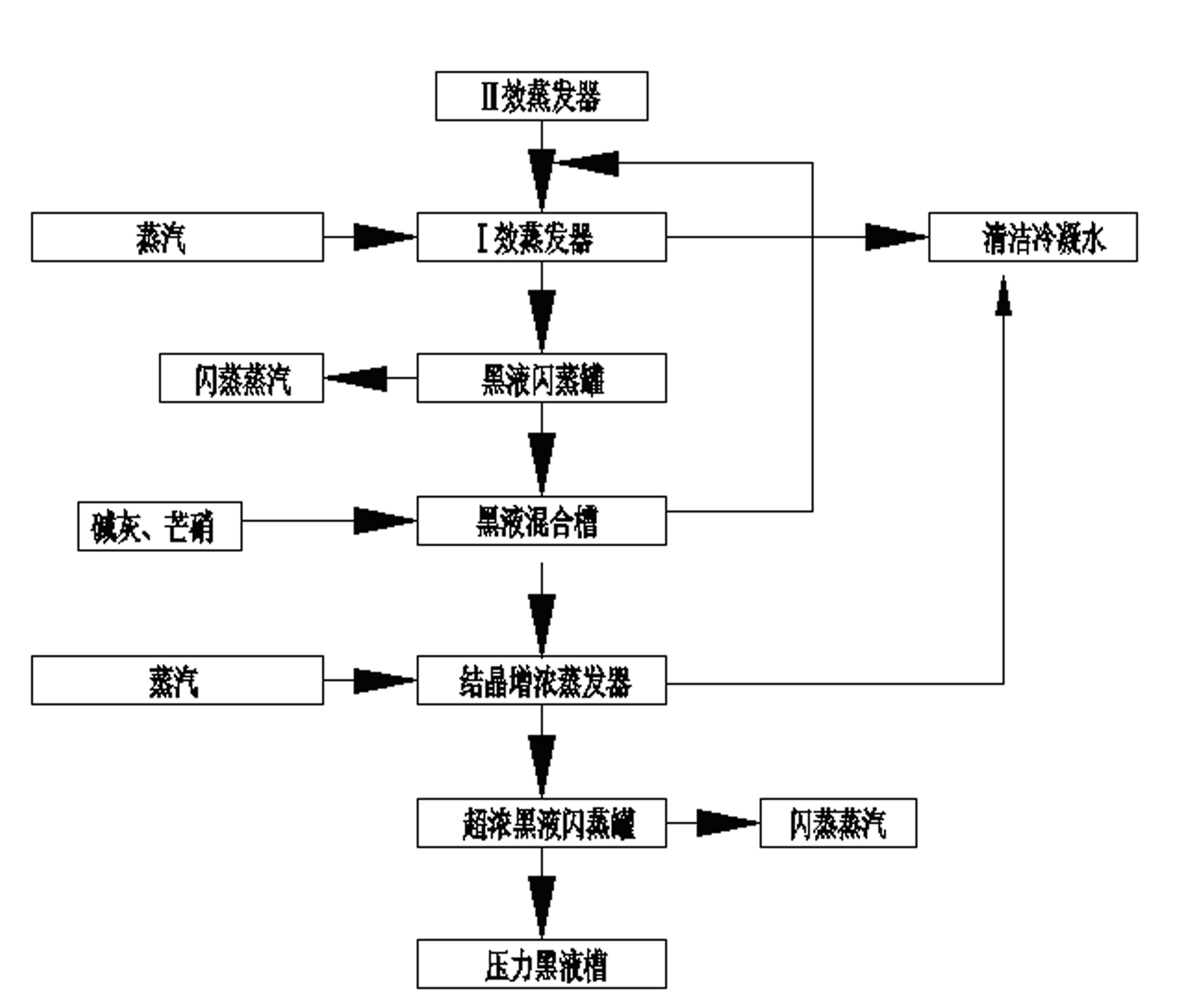

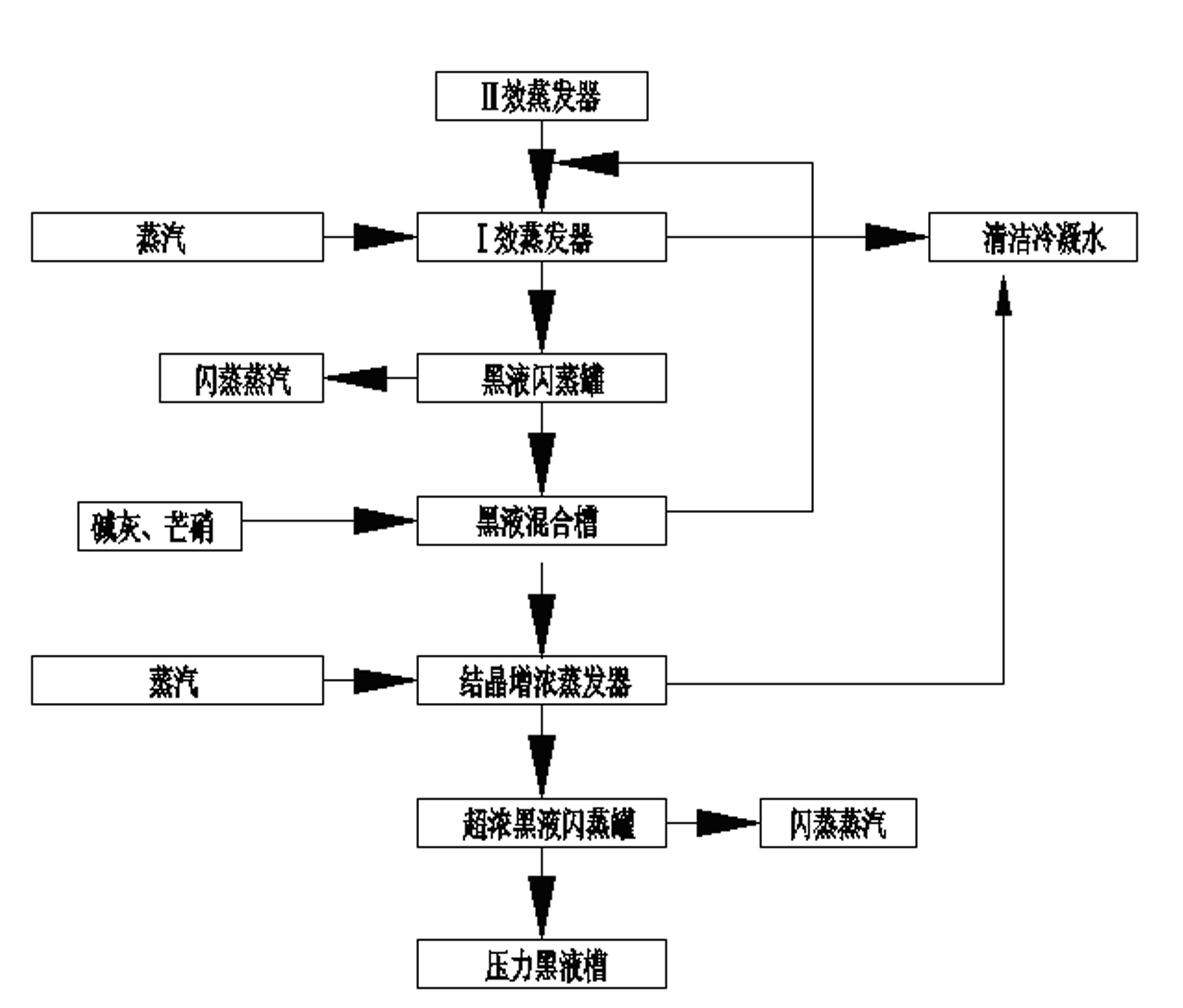

Image

Examples

Embodiment 1

[0030] In the evaporation process of six-effect plate falling film evaporation plus crystallization evaporation, the black liquor with a solid content concentration of 60wt% from the I-effect evaporator is flashed by the black liquor flash tank and then sent to the black liquor mixing tank. For the calculation of the total amount of black liquor solids in the black liquor mixing tank, add 7wt% of the soda ash collected from the alkali recovery boiler, and mix it with the black liquor evenly to generate mixed black liquor. At this time, the mixed black liquor becomes a supersaturated liquid and produces Crystal precipitation, using the crystal particles as crystal nuclei, so that more crystallization can be carried out on the crystal nuclei, preventing effective crystallization on the heating surface of the evaporator during the subsequent evaporation process, thereby effectively preventing scaling on the heating surface of the evaporator to maintain heat transfer Surface cleani...

Embodiment 2

[0032] In the evaporation process of six-effect plate falling film evaporation plus crystallization evaporation, the black liquor with a solid content concentration of 65wt% is discharged from the I-effect evaporator, and is sent to the black liquor mixing tank after being flashed by the black liquor flash tank. In the black liquor mixing tank, the total amount of black liquor solids is calculated, adding 8wt% of Glauber's salt collected from the alkali recovery alkali furnace, and mixing with the black liquor evenly to generate mixed black liquor. At this time, the mixed black liquor becomes a supersaturated liquid and produces Crystal precipitation, using the crystal particles as crystal nuclei, so that more crystallization can be carried out on the crystal nuclei, preventing effective crystallization on the heating surface of the evaporator during the subsequent evaporation process, thereby effectively preventing scaling on the heating surface of the evaporator to maintain he...

Embodiment 3

[0034] In the evaporation process of six-effect plate falling film evaporation plus crystallization evaporation, the black liquor with a solid content concentration of 58wt% from the I-effect evaporator is flashed by the black liquor flash tank and then sent to the black liquor mixing tank. To calculate the total amount of black liquor solids in the black liquor mixing tank, add 2wt% of soda ash and 2wt% Glauber's salt from the alkali recovery boiler, and mix with the black liquor evenly to generate mixed black liquor. At this time, the mixed black liquor becomes over Saturate the liquid, and produce crystal precipitation, use the crystal particles as crystal nuclei, make more crystallization proceed on the crystal nuclei, prevent the heating surface of the evaporator from crystallization during the subsequent evaporation process, and effectively prevent scaling on the heating surface of the evaporator , to keep the heat transfer surface clean; get the mixed black liquor mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com