Method for recovering gold, silver, bismuth, stibium and copper from lead anode mud

A technology for lead anode slime and gold recovery, applied in the field of bismuth, recovery of gold, antimony and copper, metal recovery, silver, to achieve the effect of low pollution, low energy consumption and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

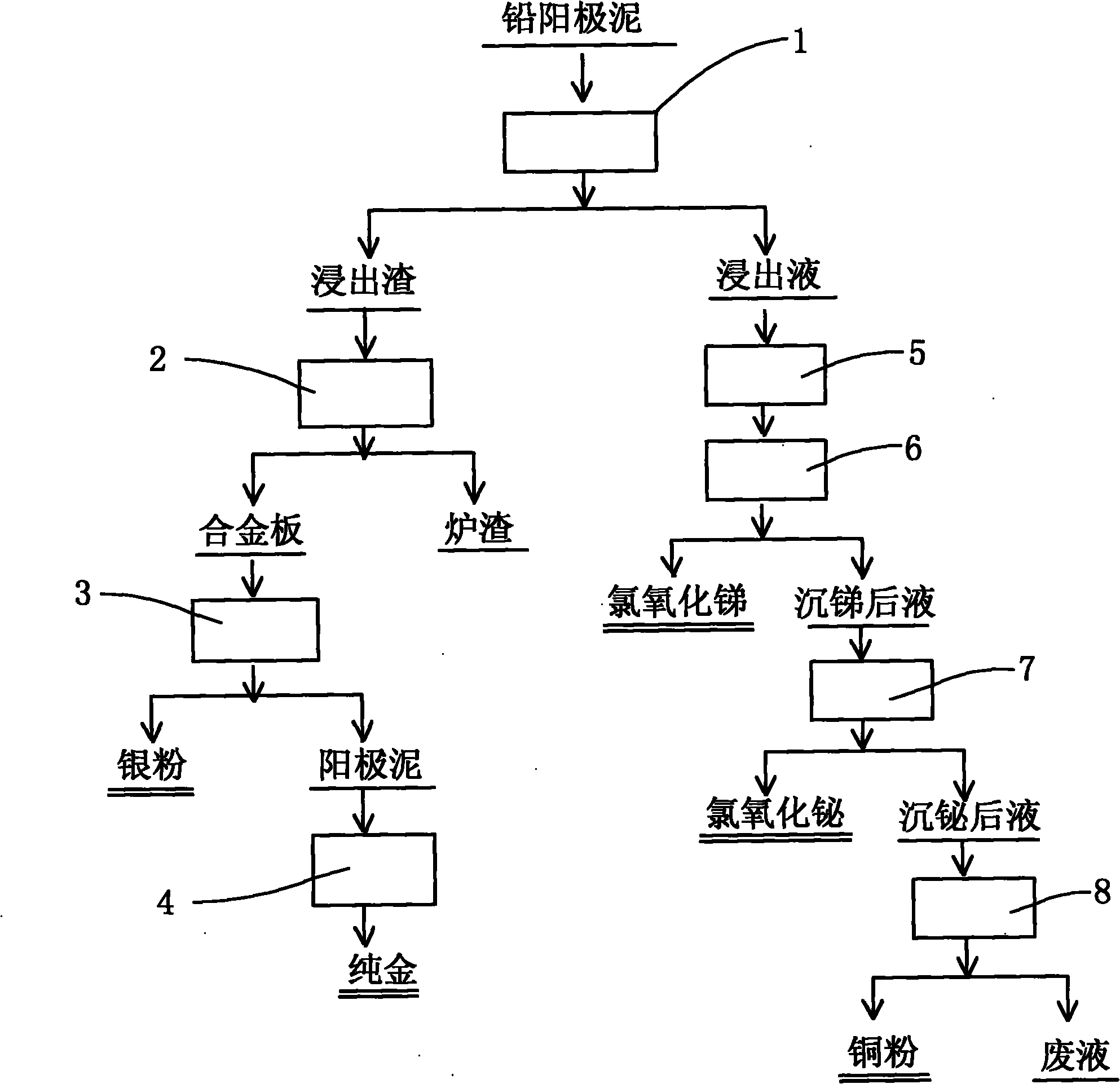

Image

Examples

Embodiment

[0028] Take 1500kg of pretreated lead anode slime, which has a water content of 10%, main components: Au 0.008%, Ag 10.7%, Sb 33.06%, Bi 22.03%, Cu 9.88%, at an initial hydrochloric acid concentration of 4mol / L, the solid-liquid ratio 1:4, at room temperature, stirring and leaching for 4h. Add 45 kg of sodium sulfide to the resulting leachate at room temperature, stir for 20 minutes, add water to dilute the volume to 8 times, adjust the pH value of the solution to 1.0, and hydrolyze and precipitate antimony until the precipitation of antimony oxychloride is complete, and the solid and liquid are separated. Add industrial sodium carbonate to the antimony-precipitated solution at room temperature under stirring conditions, adjust the pH value of the solution to 3.0 to neutralize the deposited bismuth, until the bismuth oxychloride is completely precipitated, and the solid and liquid are separated. The temperature of the bismuth-precipitated liquid is 80°C, under the condition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com