Device for preparing chlorinated polyvinyl chloride by gas-solid phase method and method thereof

A chlorinated polyvinyl chloride, gas-solid phase technology, applied in the field of chemical technology and equipment, can solve problems such as unsuitable for large-scale production, complex process flow, overheated agglomerated products, etc., to prevent sticking and discoloration, process flow Short, well-lit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the above method for preparing chlorinated polyvinyl chloride, the raw material gas is pure chlorine gas or nitrogen gas or a mixture thereof; the particle size of the raw material PVC is 25-500 μm.

[0042] In the above method for preparing chlorinated polyvinyl chloride, the operating pressure in the riser reactor is 0.05-0.1 MPa, and the one-way residence time of PVC particles in the riser reactor is 0.5-2 min.

[0043] In the above method for preparing chlorinated polyvinyl chloride, the operating pressure of the turbulent fluidized bed reactor is 0.05-0.1 MPa, and the one-way residence time of PVC particles is 10-40 min.

Embodiment 1

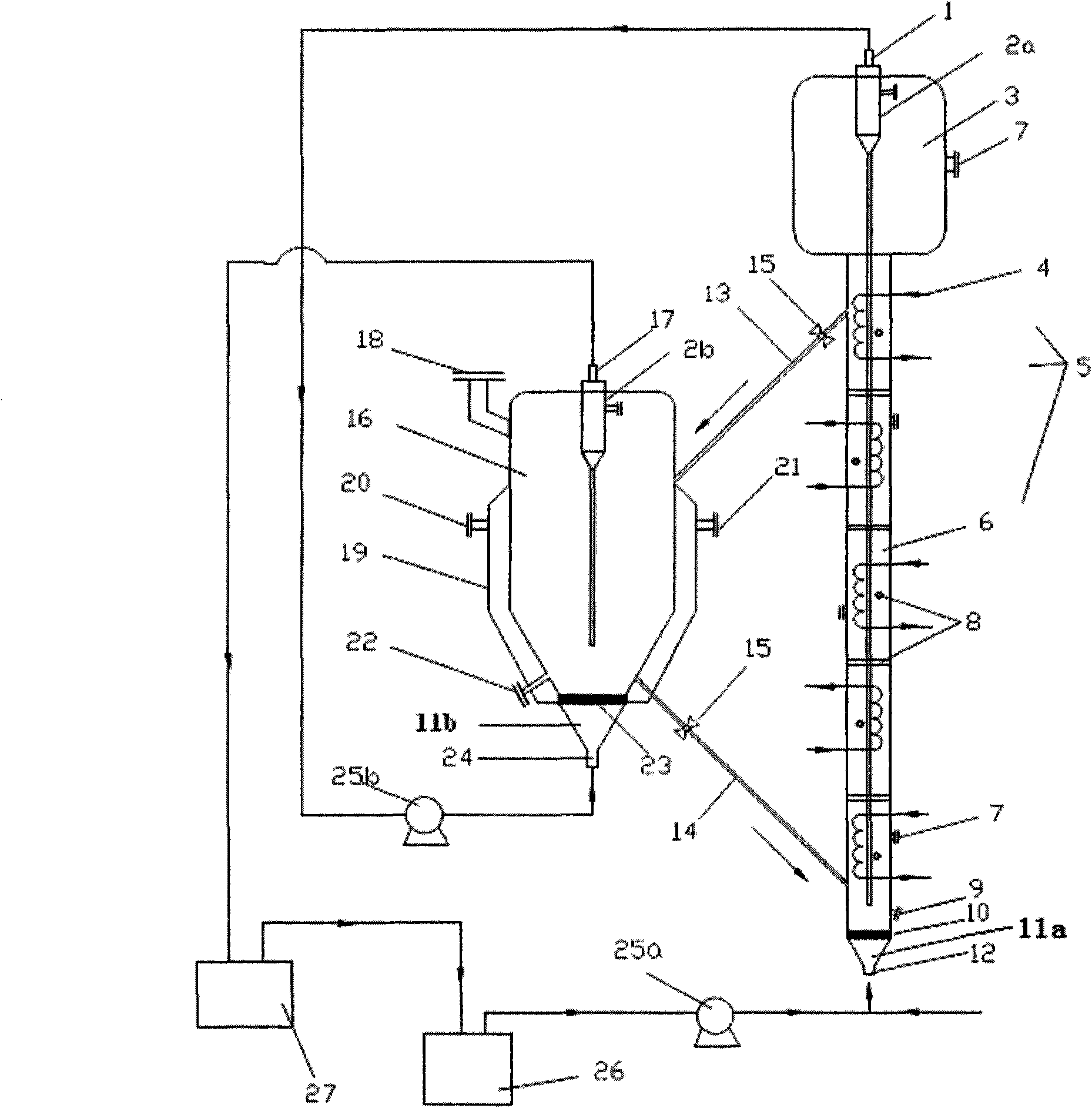

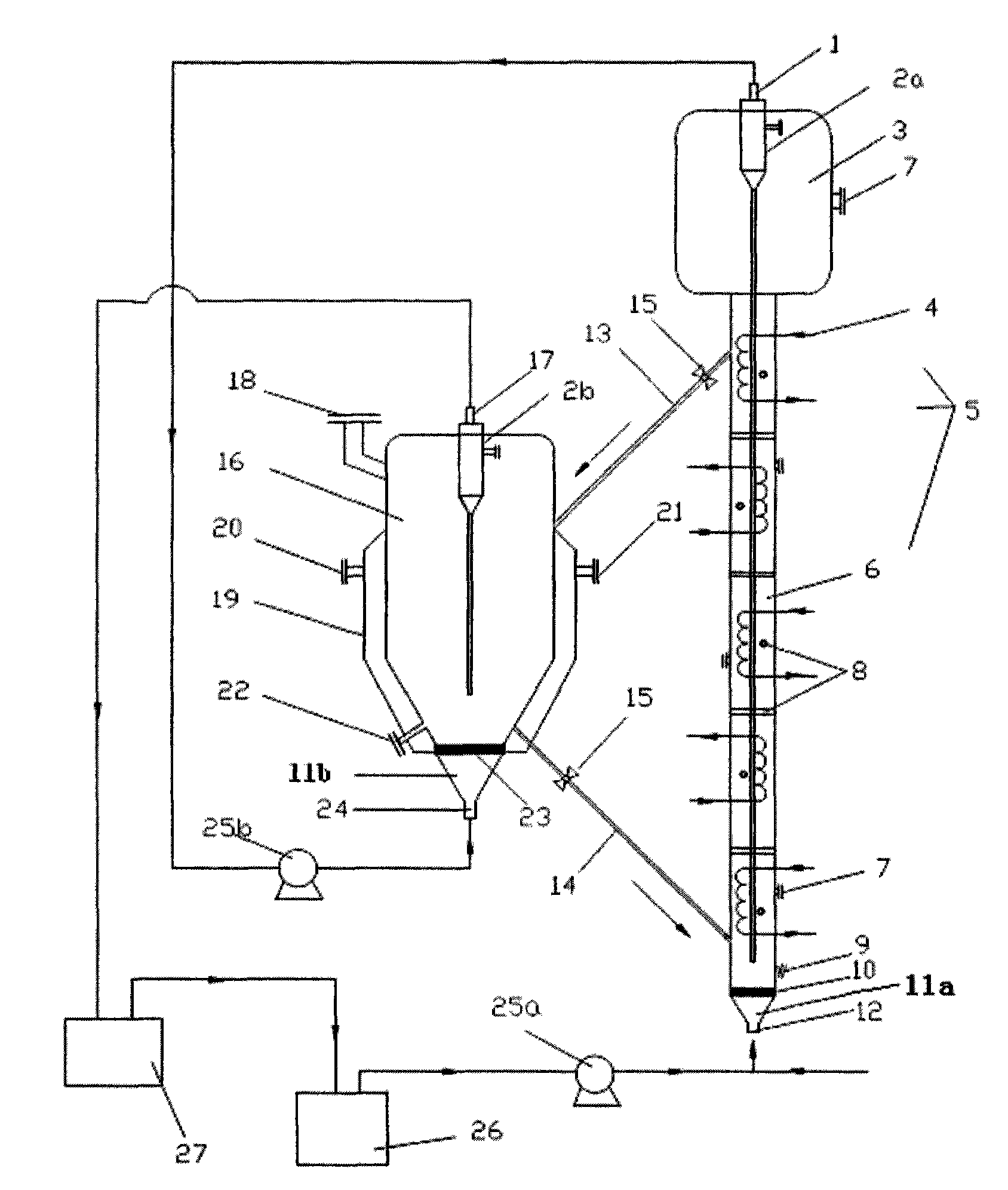

[0045] in such as figure 1 In the shown device of the present invention, PVC with a particle diameter of 100-150 μm is used as raw material, the raw material gas is pure chlorine gas, and pure chlorine gas is chlorinated, the chlorination temperature is 100-110 °C, and the operating pressure in the riser reactor is 0.05 MPa , the one-way residence time of the particles is 1min, the operating pressure in the turbulent fluidized bed reactor is 0.08MPa, and the one-way residence time of the particles is 10min. After the reaction for 1h, the chlorine content of the product CPVC is 68%, which fully meets the requirements of the CPVC content.

Embodiment 2

[0047] in such as figure 1 In the shown device of the present invention, PVC with a particle diameter of 150-200 μm is used as a raw material, the raw material gas is a mixed gas of chlorine and nitrogen containing 30% chlorine, the chlorination temperature is 110-120 °C, and the operating pressure in the riser reactor is The one-way residence time of particles is 0.05MPa, the one-way residence time of particles is 2min, the operating pressure in the turbulent fluidized bed reactor is 0.06MPa, and the one-way residence time of particles is 20min. After 1.5h of reaction, the chlorine content of the product CPVC is 69%, which fully meets the CPVC content requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com