System and method for removing phosphorus by three-mud process nitrification and denitrification

A denitrification phosphorus removal and treatment system technology, applied in the field of urban sewage treatment, can solve the problems of large area, high phosphorus content in sludge, ammonia nitrogen cannot meet high discharge standards, etc., to reduce infrastructure and operating costs, improve The effect of nitrogen and phosphorus removal, the effect of overcoming the slow rate of nitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

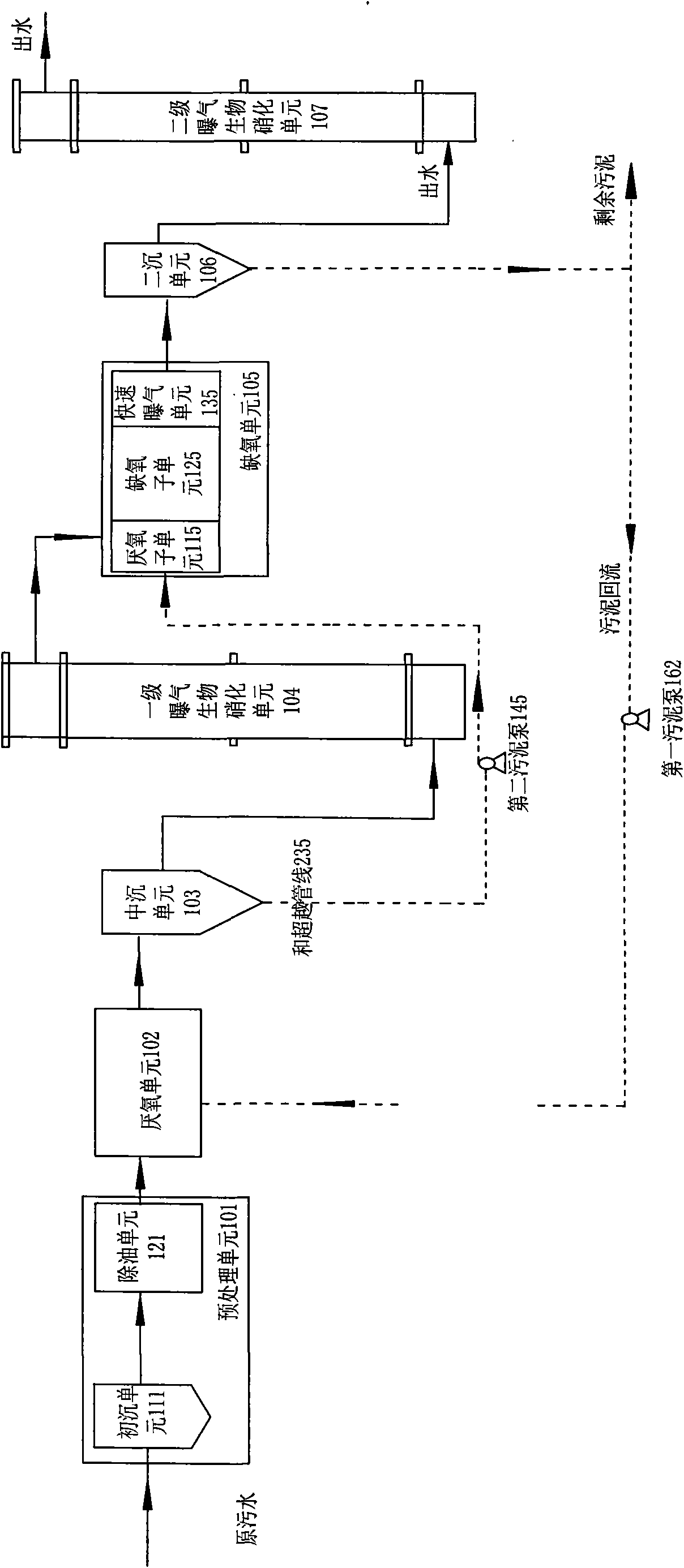

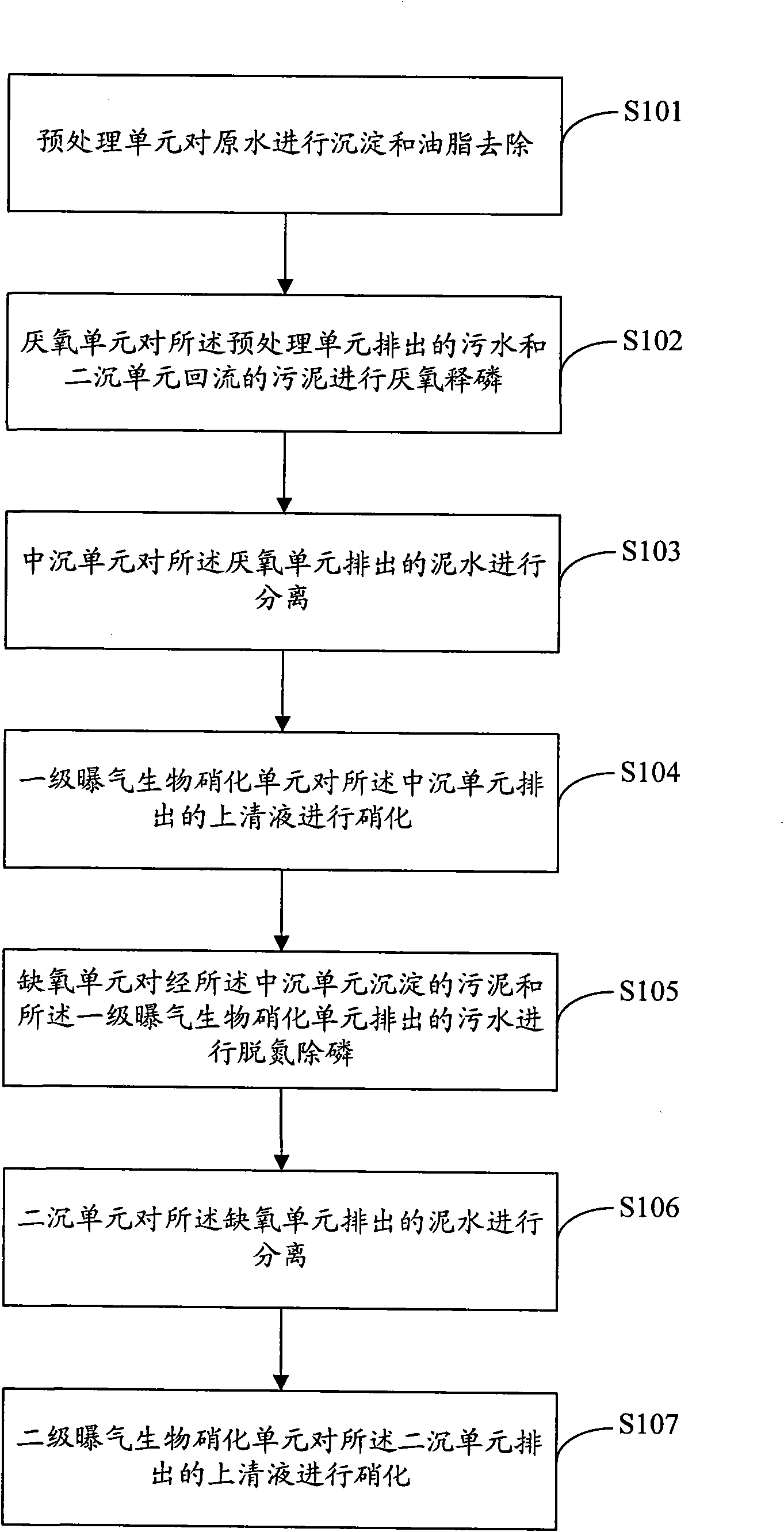

[0053] figure 1 It is a structural schematic diagram of the nitrification and denitrification phosphorus removal treatment system of the present invention. Such as figure 1 As shown, the three-sludge method nitrification and denitrification phosphorus removal treatment system includes a pretreatment unit 101, anaerobic unit 102, middle sink unit 103, primary aeration biological nitrification unit 104, anoxic unit 105, secondary sink unit 106 and two Stage aerated biological nitrification unit 107.

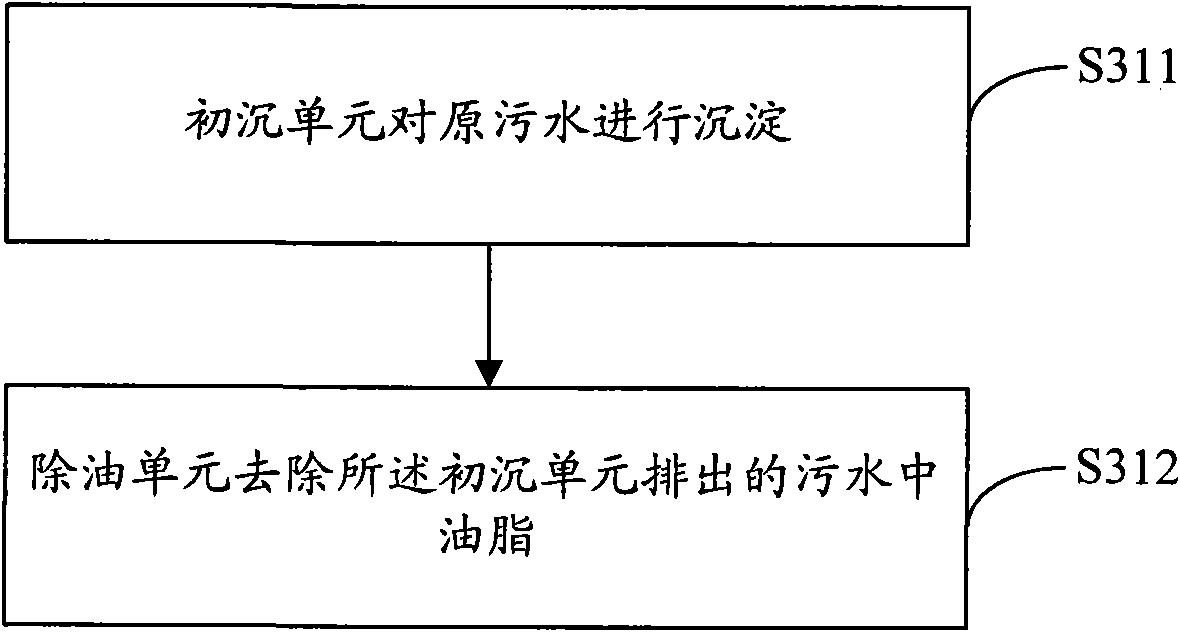

[0054] The pretreatment unit 101 is used for precipitating raw water and removing grease. In a preferred technical solution of the present invention, the pretreatment unit 101 specifically includes a primary sedimentation unit 111 and an oil removal unit 121 . Wherein, the primary sedimentation unit 111 precipitates the raw water. The sewage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com