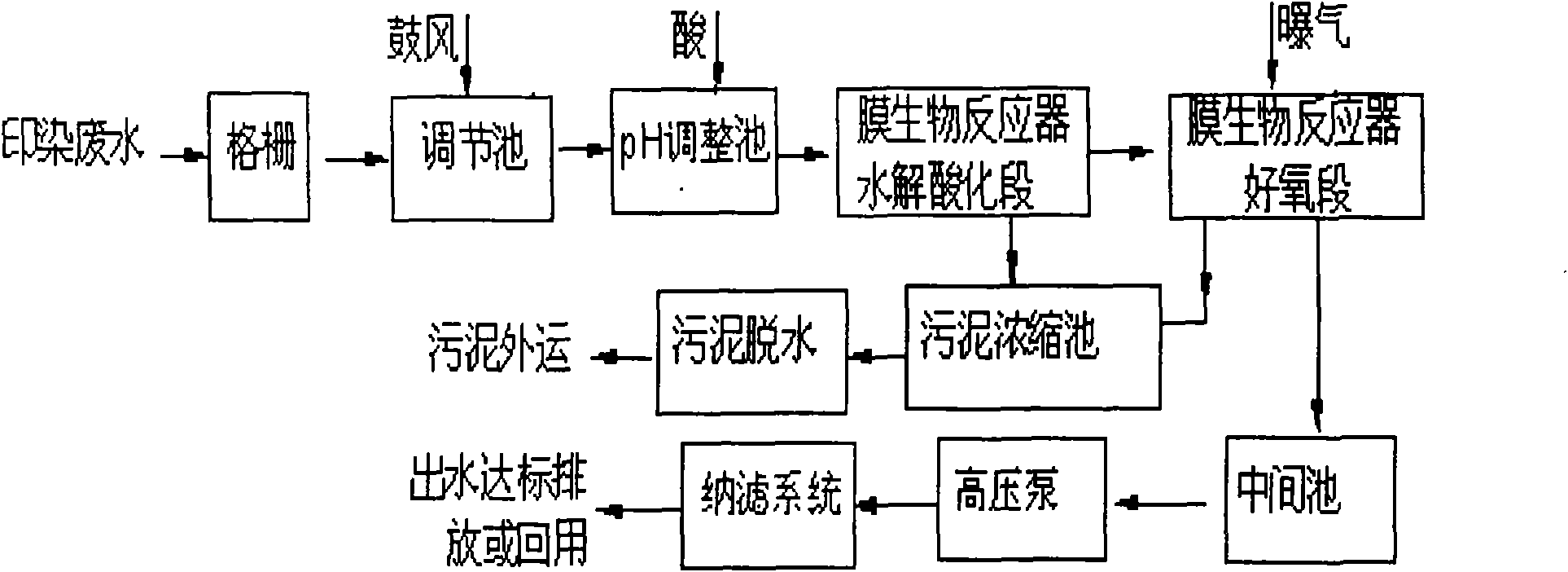

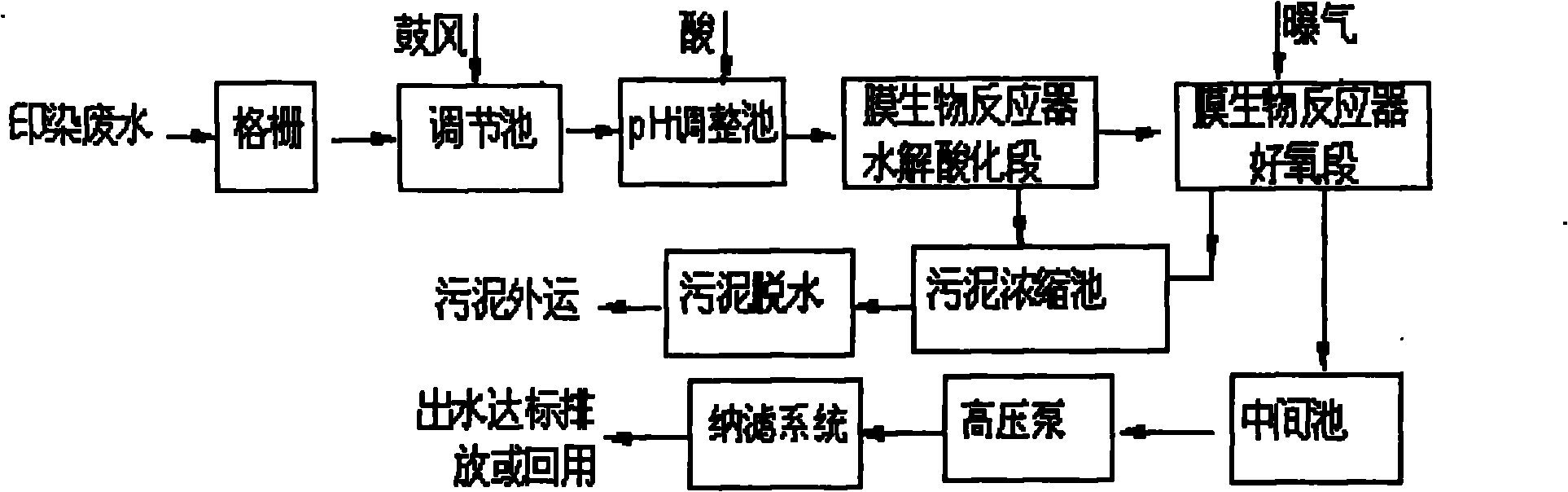

Treatment method of printing and dying wastewater

A printing and dyeing wastewater and treatment method technology, applied in the field of industrial water treatment, can solve the problems of large consumption of electrode materials, high operating costs, and difficult post-treatment, etc., to improve the effect of biochemical treatment, increase the processing load capacity, and occupy an area of facilities small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The chemical oxygen demand of printing and dyeing wastewater is 2000-3000mg / L, the chromaticity is 1000-1200 times, and the pH value is 8-10.

[0020] (1) Remove large suspended solids and garbage in the printing and dyeing wastewater through the grid. The grill adopts two layers of thick and thin, the gap of the coarse grill is 15mm, the gap of the fine grill is 3mm, the installation angle is 60°, and the slag is cleaned manually.

[0021] (2) Homogenize the water quality and quantity of printing and dyeing wastewater through the regulating tank, and the residence time is 1 day. A perforated aeration tube is set in the adjustment pool to aerate regularly and stir evenly the water quality of the printing and dyeing wastewater.

[0022] (3) Adjust the pH value to 7.5 through the pH adjustment tank and enter the membrane bioreaction tank.

[0023] (4) Through the hydrolysis and acidification section of the membrane bioreactor, complex macromolecules, insoluble organic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com