Pressure machine closed height adjusting device and control system thereof

A closed height and adjustment device technology, applied in the field of forging machinery, can solve the problems of difficult manufacturing, high failure rate, troublesome adjustment, etc., and achieve the effect of effective safety, low failure rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

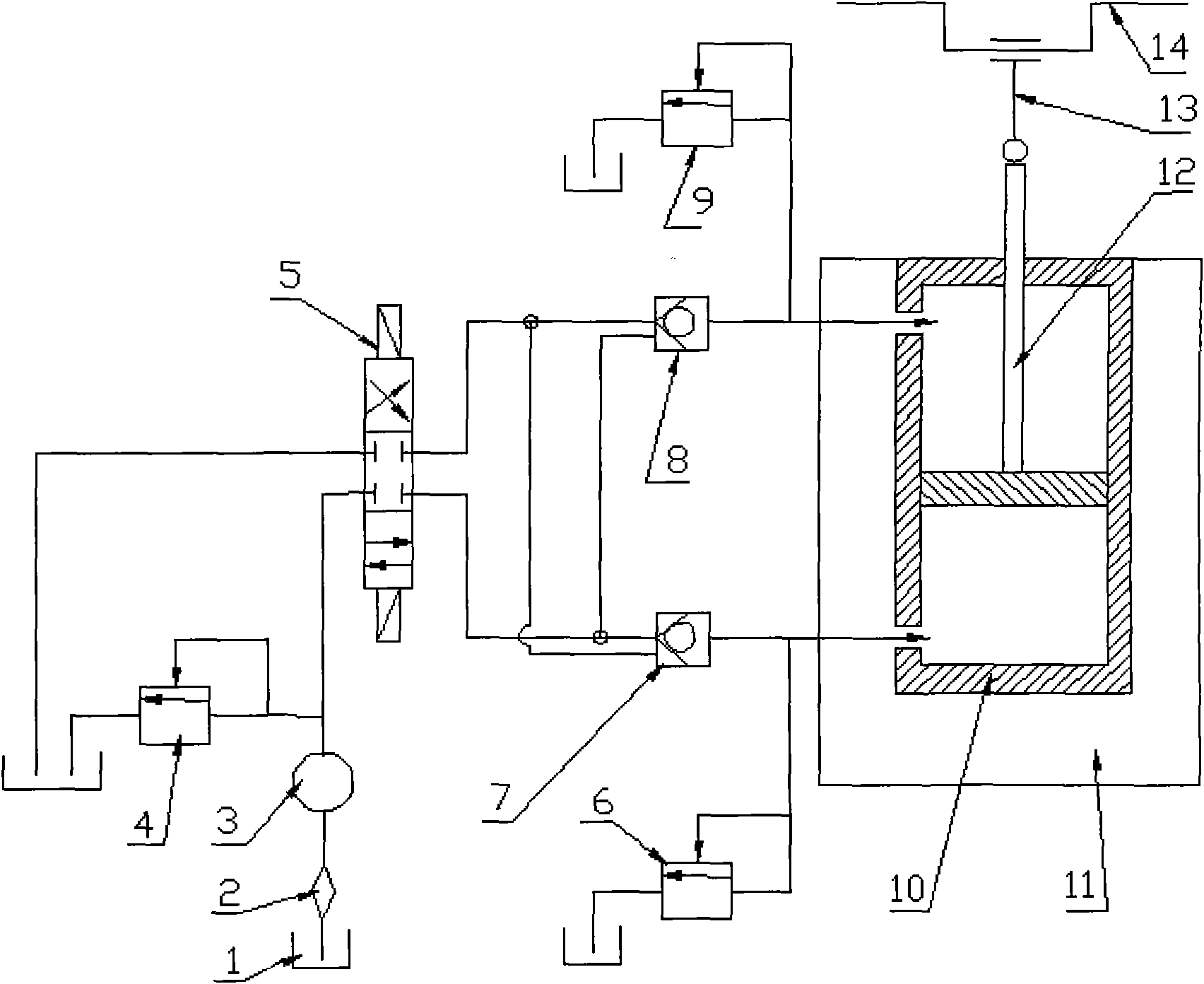

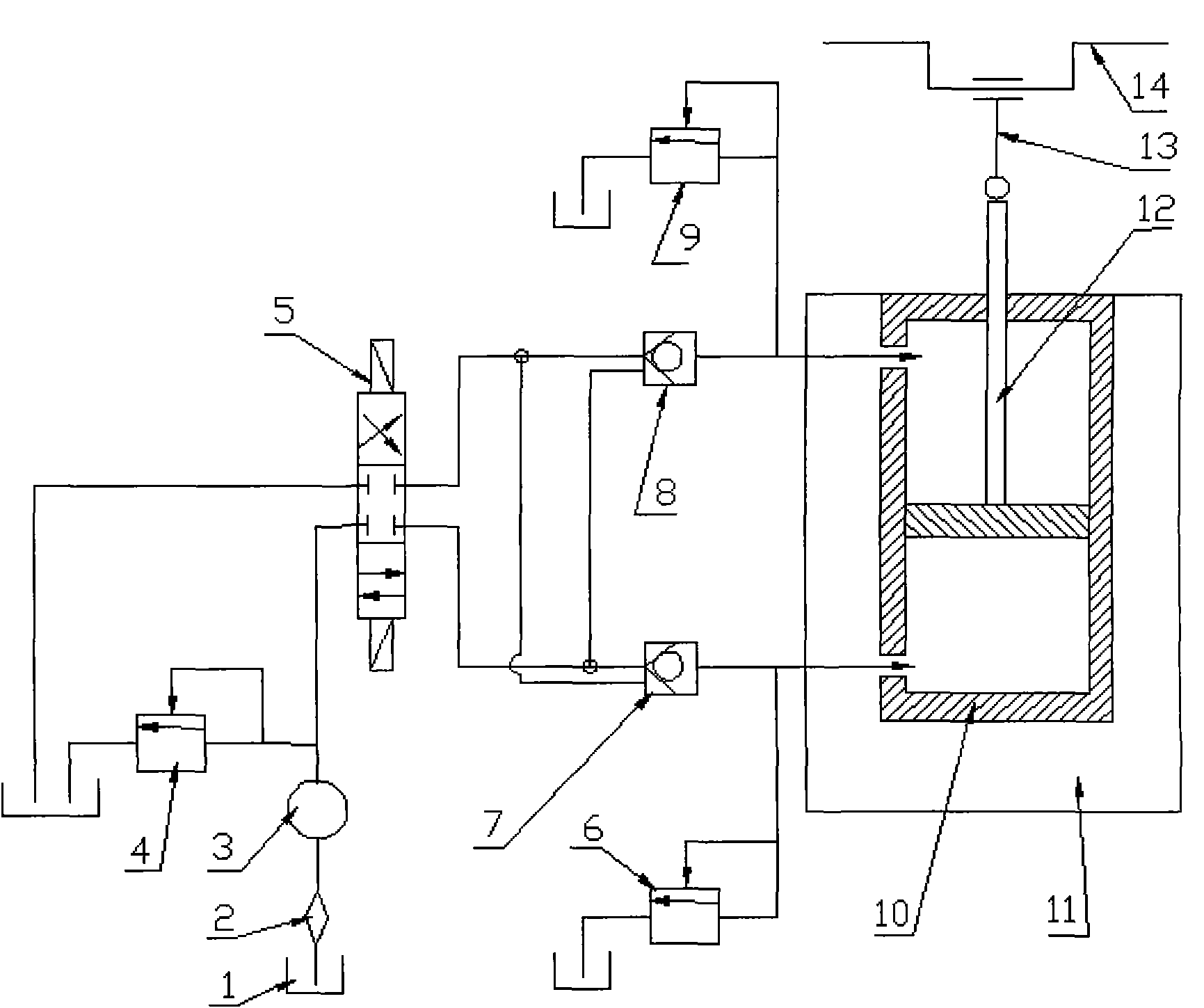

[0009] The hydraulic cylinder (10) and the sliding block (11) may be in the form of a conjoined structure or a separate structure, and the piston rod (12) of the hydraulic cylinder (10) and one end of the connecting rod (13) are hinged to each other. Together, the other end of the connecting rod (13) is connected to the crankshaft (14) by a suitable means. The oil inlet and outlet of the upper chamber of the hydraulic cylinder (10) are connected with the upper cylinder hydraulic control check valve (8) and the upper cylinder safety valve (9) by means of three-way joints. The upper cylinder hydraulic control check valve (8) The installation of the upper cylinder safety valve (9) and the oil cylinder connected to it can form a back pressure relationship; at the oil inlet and outlet of the lower chamber of the hydraulic cylinder (10), three-way joints are used to respectively connect with the lower cylinder hydraulic control check valve (7). ) and the lower cylinder safety valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com