Reactor and method for realizing completely-mixed flow of gas-phase or gas-solid two-phase fluid

A reactor and fully mixed flow technology, applied in chemical instruments and methods, chemical/physical/physicochemical nozzle reactors, mixers, etc., can solve the problem of solids breaking into debris, complex structures, difficult to stirrer or propeller High speed and other problems, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached

[0030] The drawings and specific embodiments illustrate the present invention in further detail.

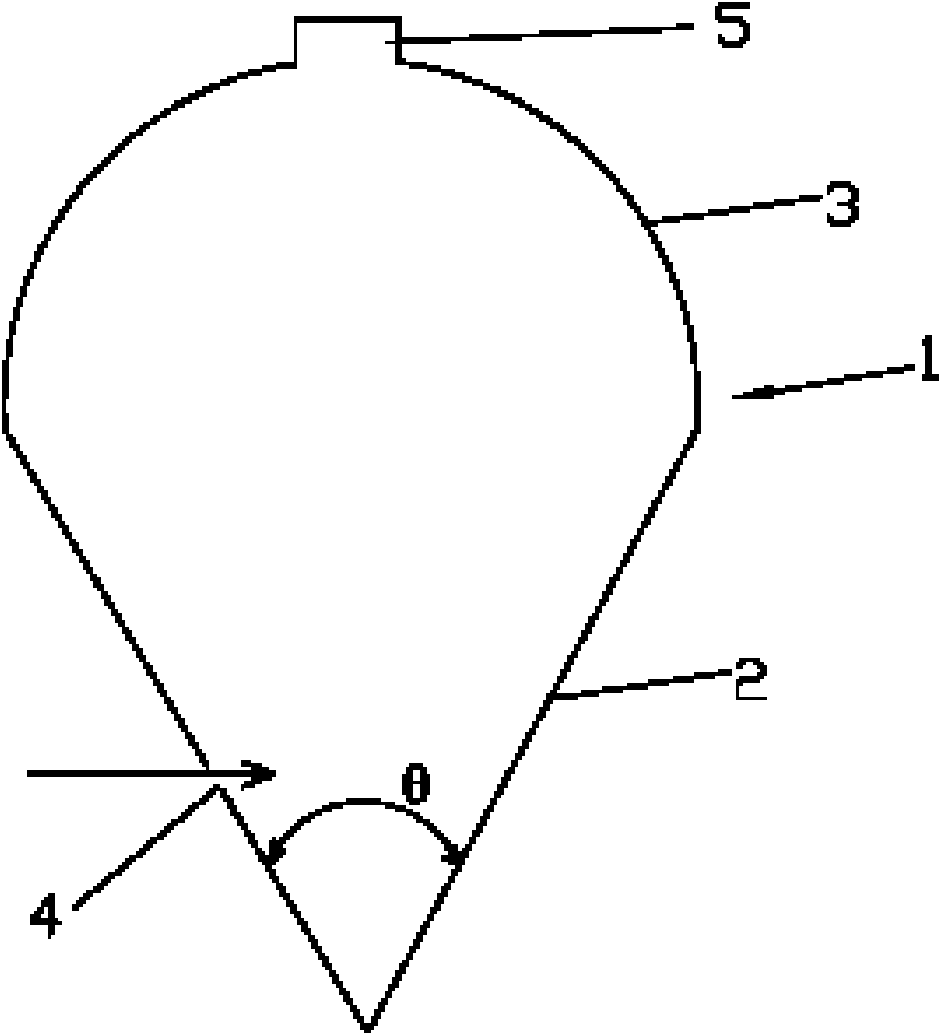

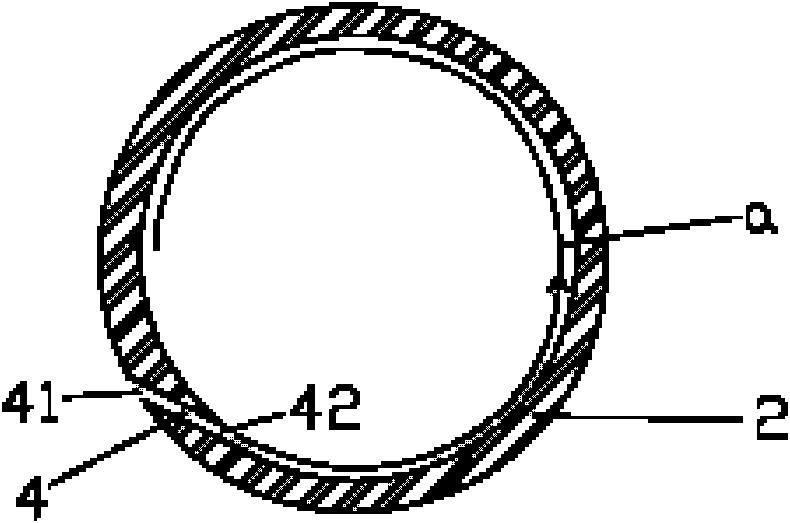

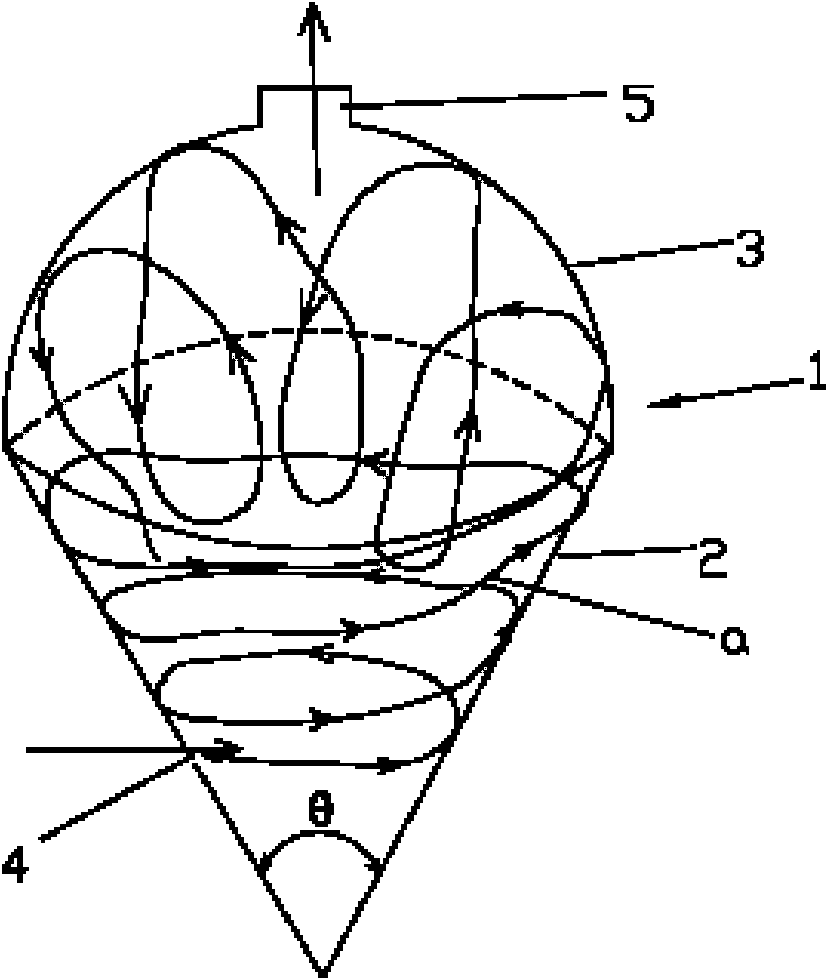

[0031] refer to figure 1 and figure 2 , the reactor in which gas phase or gas-solid two-phase fluid realizes fully mixed flow, including upper and lower parts connected to each other, the lower part is an inverted cone, the upper part is a spherical crown, and the inverted cone 1 is provided with a gas inlet The gas outlet 4 is provided on the top of the reactor, and the gas feed channel is arranged along the tangential direction of the circumference of the lower rotating body of the reactor. During the gas-phase homogeneous reaction, the gas feed channel only feeds gas; during the gas-solid phase heterogeneous reaction, the gas feed channel can simultaneously feed gas and catalyst, and the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com