Electric kettle capable of automatically shutting off steam channel

A steam channel and automatic shut-off technology, which is applied to water-boiling utensils, cooking utensils, household utensils, etc., can solve the problems of troublesome cleaning, slow reset of the induction switch, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

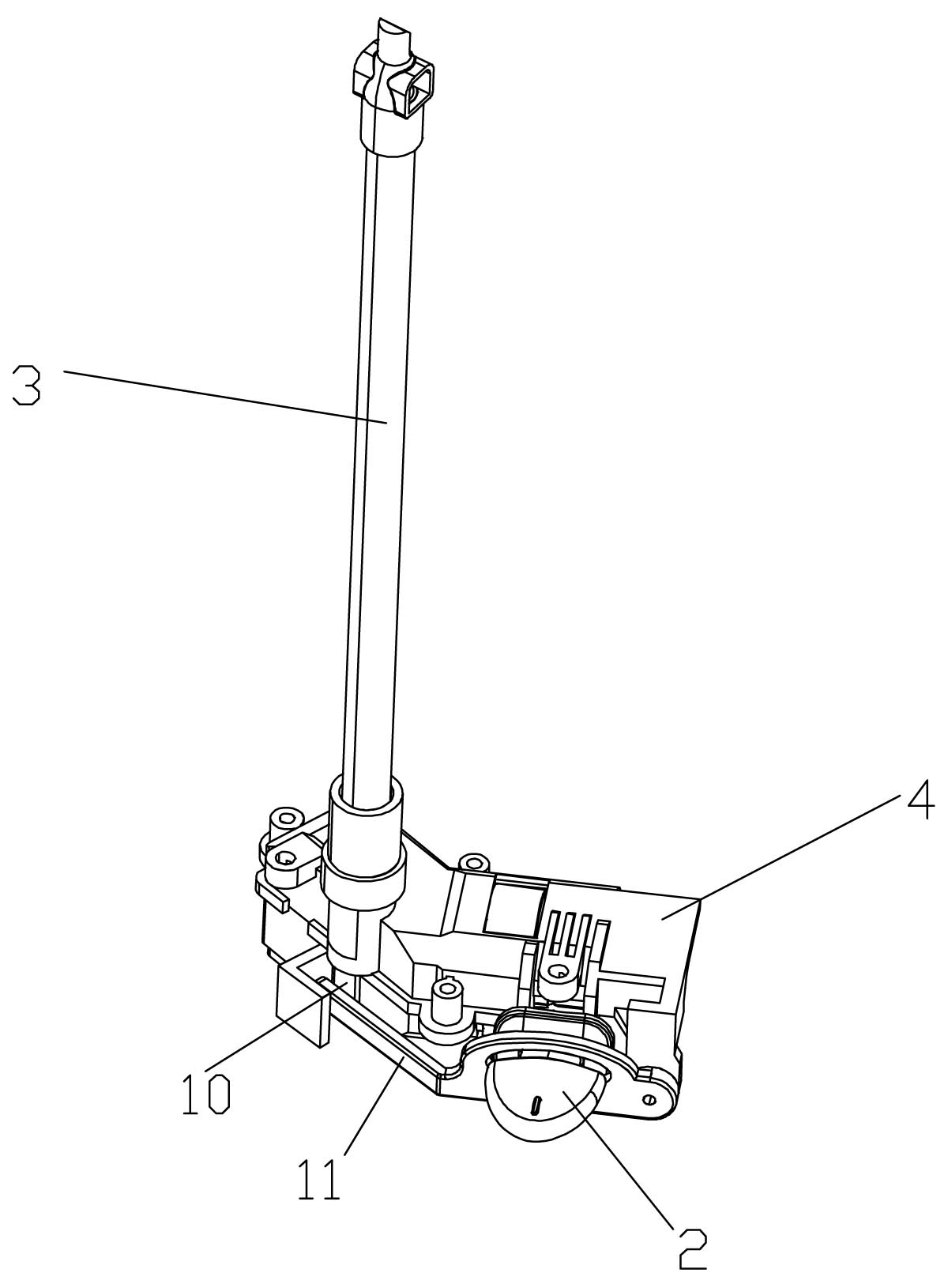

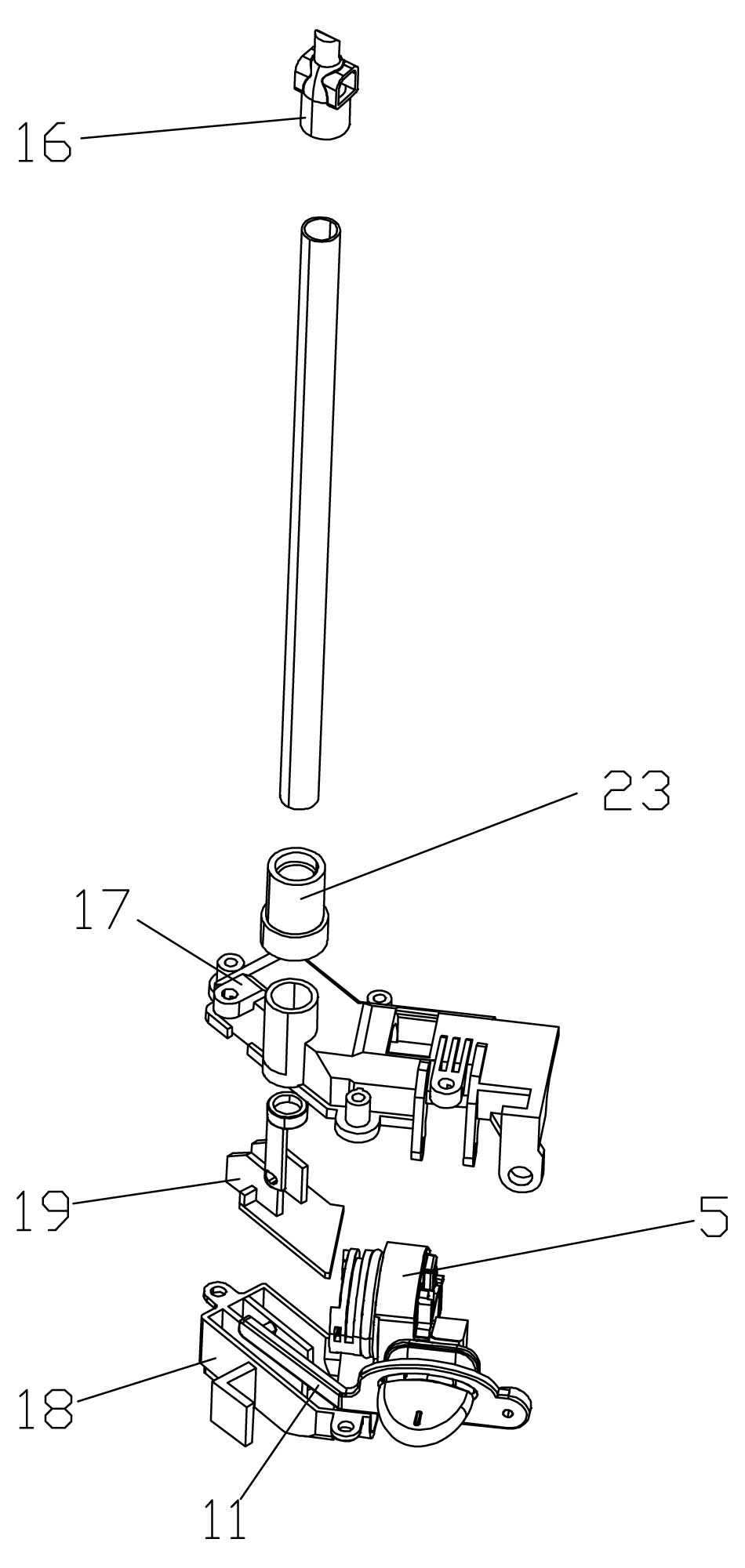

[0019] refer to Figure 1 to Figure 6 , an electric kettle that automatically shuts off the steam channel provided by the present invention includes a kettle body 1 and a switch button 2 installed on the kettle body 1. In order to realize the automatic shutdown function according to the temperature inside the kettle body 1, the The switch button 2 communicates with the inside of the kettle body 1 through the steam passage assembly, the steam passage assembly includes a steam pipe 3 and a steam box 4, and the two ends of the steam pipe 3 communicate with the interior of the kettle body 1 and the steam box 4 respectively, and the steam When the pipe 3 communicates with the inside of the steam box 4, it can be directly plugged in or connected with an auxiliary part 23. A steam sensor switch 5 is installed across the steam box 4, and a steam sensor switch 5 communicates with the steam tube. One side is provided with a bimetal 6, and the other side of the steam induction switch 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com