Upper suction compact spinning ring bobbin

A technology of compact spinning and spinning frames, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve the problems of inability to meet the negative pressure requirements of compact spinning and large negative pressure difference, and achieve operation and Low maintenance cost, small negative pressure difference and low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

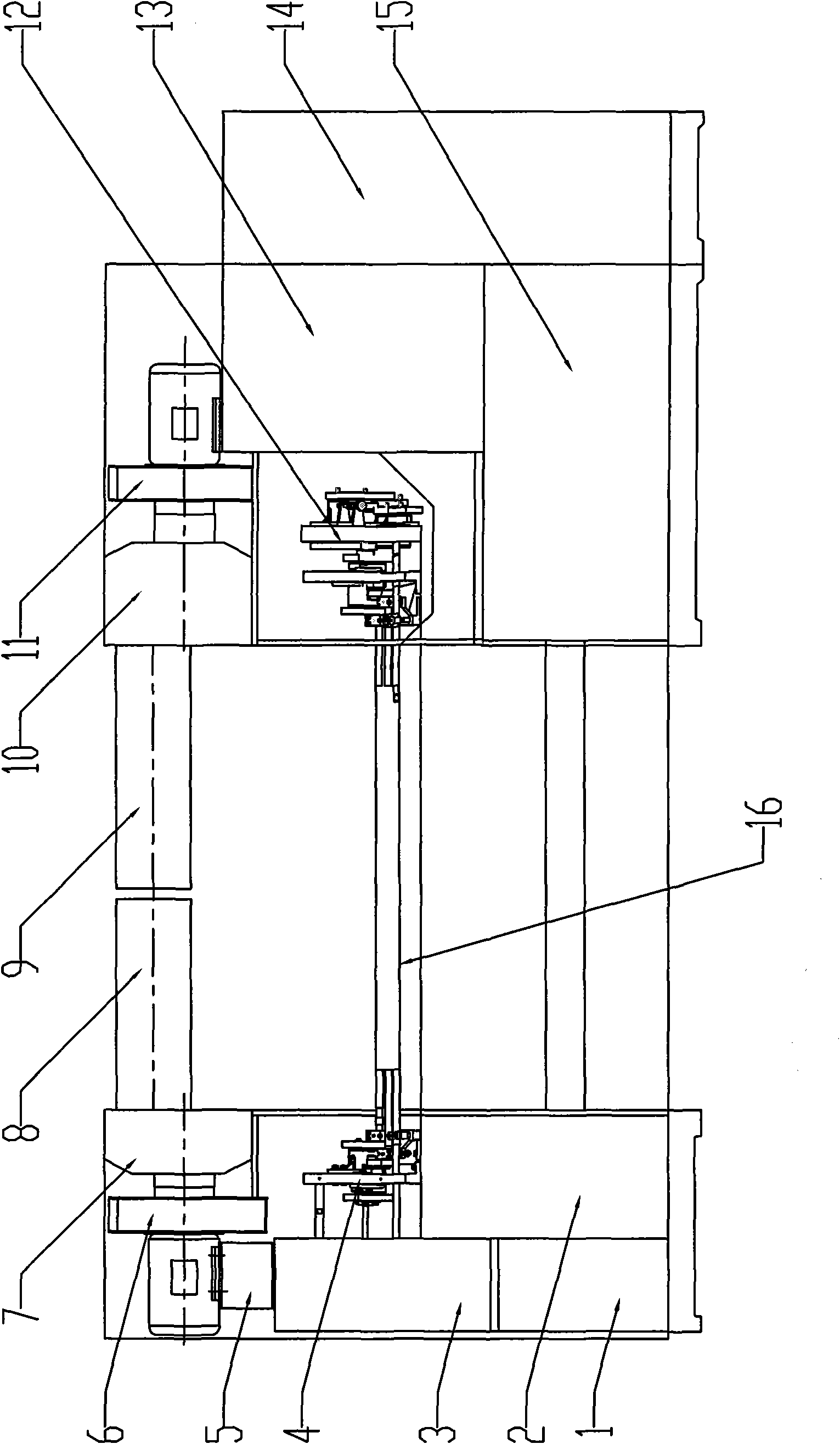

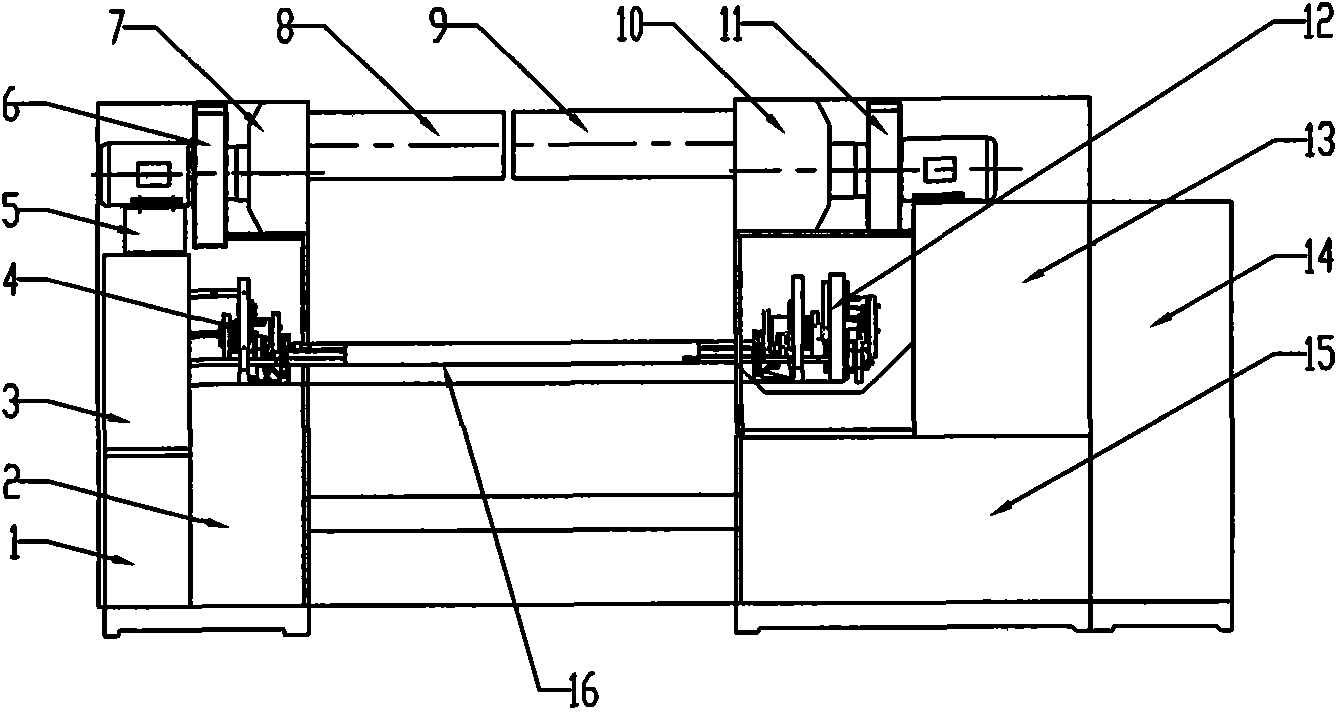

[0011] A top-suction compact spinning ring spinning machine, which includes a lifting part 1, a lifting distribution part 2, a gear transmission part 3, a headstock drafting part 4, a headstock compact spinning fan mounting seat 5, a headstock compact spinning fan 6, and a headstock compact spinning machine. Spinning bellows 7, headstock compact spinning suction pipe 8, rear compact spinning suction pipe 9, rear compact spinning bellows 10, rear compact spinning fan 11, rear drafting parts 12, cotton suction bellows 13, electric control cabinet 14. The main transmission part 15 and the middle part 16 of the compact spinning frame, the lifting part 1 is set on the spinning machine head, the lifting distribution part 2 is set on the right side of the lifting part 1, the gear transmission part 3 is set on the top of the lifting part 1, The headstock drafting part 4 is arranged on the top of the lifting distribution part 2 and connected with the gear transmission part 3, the headst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com