Method for preparing common-activity calcium carbonate series product and co-producing ammonia chloride

A technology for active calcium carbonate and series products, which is applied in the field of preparing common active calcium carbonate series products for co-production of ammonium chloride, can solve the problem of complex production methods, production processes and equipment that do not have the preparation of common active calcium carbonate series products for co-production of ammonium chloride , high cost and other issues, to achieve the effect of small investment, low cost and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

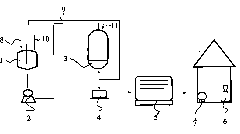

Image

Examples

Embodiment 1

[0027] Use 500 kg of limestone coarse powder to mediate into an emulsion, and the limestone coarse emulsion is injected into the reactor 1 through the calcium carbonate feed line 8, and then ammonium chloride is injected into the reactor, wherein the limestone emulsion and the dissolved ammonium chloride According to the mass ratio of pure substances 1: 0.87 mixed in the reactor for reaction, mixed in the reactor, the rotating speed of the agitator is 60 rpm, the reaction generates carbon dioxide and water, and the carbon dioxide is transported to the ammonium with the pipeline 9 of the carbon dioxide circulation line. Recycle in the carbonizer, and suction filter pump 2 gets 536.5 kilograms of calcium chlorides.

[0028] Calcium chloride is evenly mixed and injected into the ammonium carbonizer 3 as mother liquor, which contains ammonium hydroxide configured in advance with a mass ratio of 1:0.95; start the stirrer to make the mixed solution uniform and carry out ammonium carb...

Embodiment 2

[0030] Use 500 kg of limestone coarse powder to mediate into an emulsion, and the limestone coarse emulsion is injected into the reactor 1 through the calcium carbonate feed line 8, and then ammonium chloride is injected into the reactor, wherein the limestone emulsion and the dissolved ammonium chloride According to the mass ratio of pure substances 1: 1.07 mixed in the reactor for reaction, mixed in the reactor, the reaction generates carbon dioxide and water, the carbon dioxide is transported to the ammonium carbonizer by the pipeline 9 of the carbon dioxide circulation line for recycling, and the suction filter pump 2 Suction filtration yielded 659.8 kg of calcium chloride.

[0031] Calcium chloride is evenly mixed and injected into the ammonium carbonizer 3 as mother liquor, which contains ammonium hydroxide configured in advance with a mass ratio of 1:0.95; start the stirrer to make the mixed solution uniform and carry out ammonium carbonization, that is, under the situat...

Embodiment 3

[0033] Use 500 kg of limestone coarse powder to mediate into an emulsion, and the limestone coarse emulsion is injected into the reactor 1 through the calcium carbonate feed line 8, and then ammonium chloride is injected into the reactor, wherein the limestone emulsion and the dissolved ammonium chloride According to the mass ratio of pure substances 1: 1.27 mixed in the reactor for reaction, mixed in the reactor, the reaction generates carbon dioxide and water, carbon dioxide is transported to the ammonium carbonizer by the pipeline 9 of the carbon dioxide circulation line for recycling, and the suction filter pump 2 Suction filtration yielded 783.2 kg of calcium chloride.

[0034]Calcium chloride is evenly mixed and injected into the ammonium carbonizer 3 as a mother liquor, which contains ammonium hydroxide configured in advance with a mass ratio of 1: 1.15; start the stirrer to make the mixed solution uniform and carry out ammonium carbonization, that is, under the situatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com