Accumulator grid

A battery and grid technology, applied in the direction of electrode carrier/collector, etc., can solve the problems of outflow, uneven potential distribution, large internal voltage drop of the battery, etc., and achieve the effect of prolonging the service life and shortening the conduction path of the current

Inactive Publication Date: 2010-09-01

JIANGSU OLITER ENERGY TECH

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Currently used as a battery grid, the grid with vertical vertical ribs is generally used. The battery plate made of this structure grid has a long current conduction path, which causes a large internal pressure drop of the battery, resulting in The reduction of output power; when used as a starting battery, the large discharge capacity at the moment of high-power output will cause de-current, so that the current and potential distribution on the grid will be uneven, and the lead paste on the plate will change unevenly and fall off. , not only reduces the holding capacity of the lead paste, but also causes the connection between the positive and negative electrodes, resulting in an increase in self-discharge, which reduces the capacity and the service life of the battery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

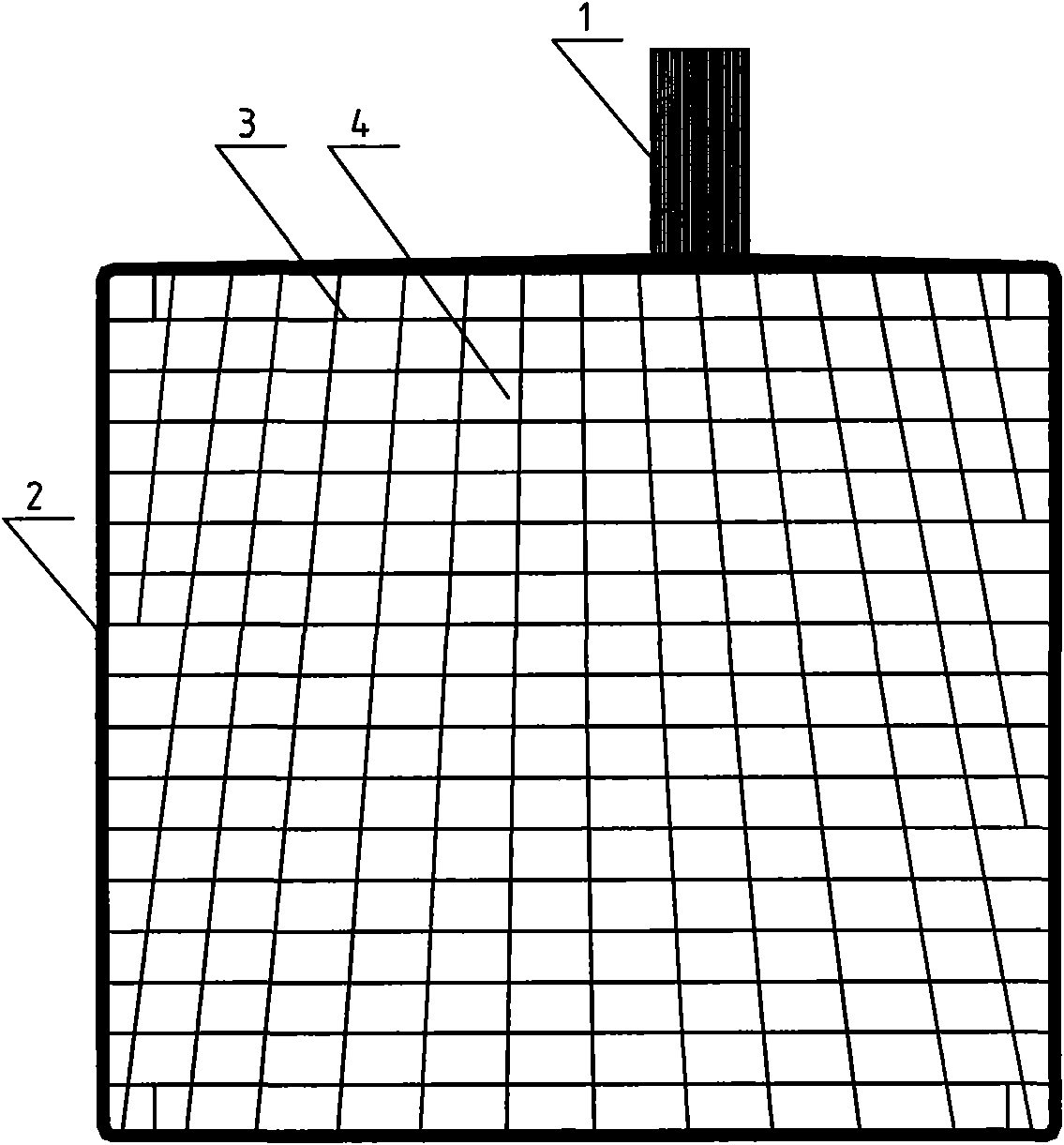

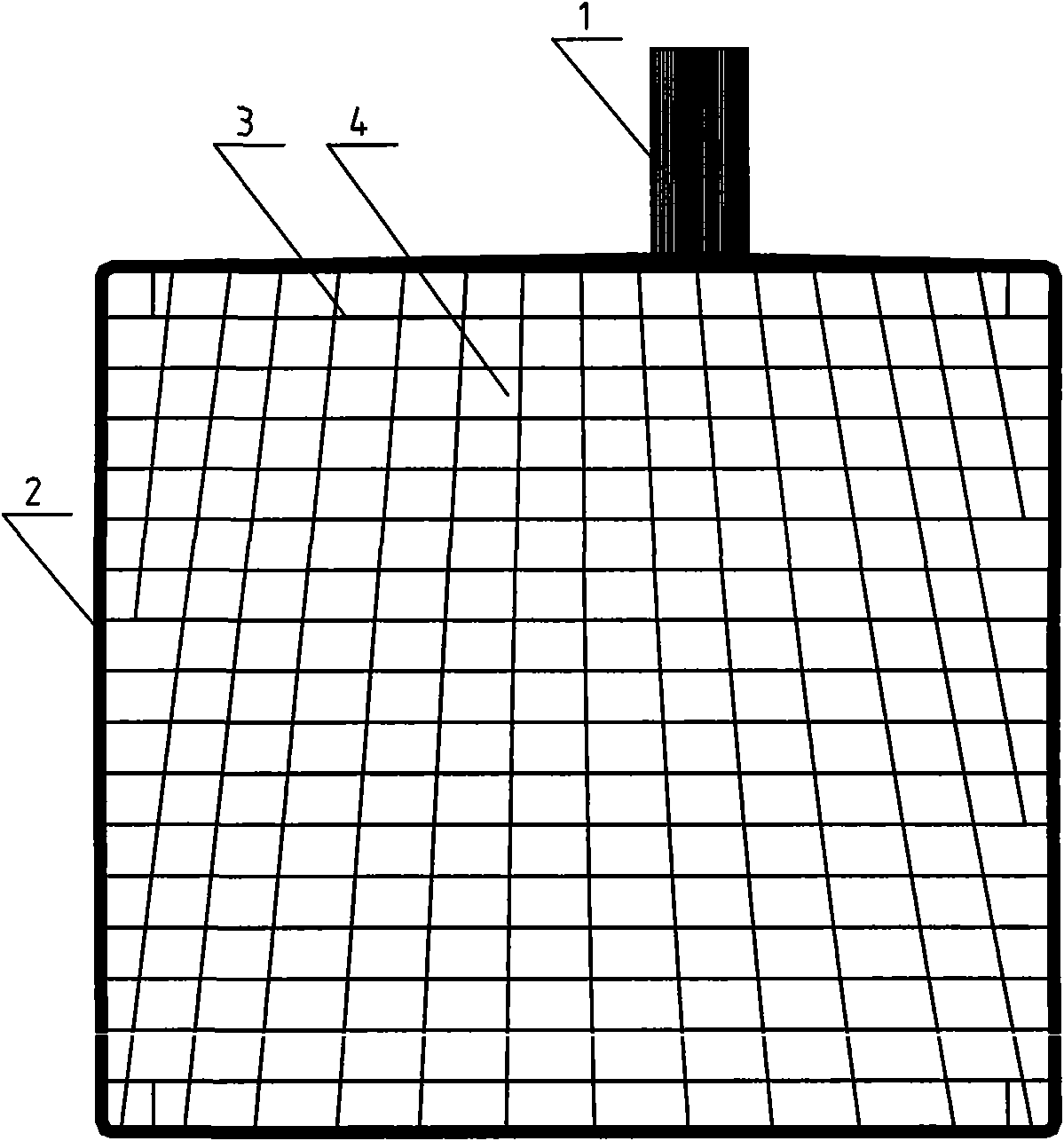

[0008] The present invention includes a tab 1, a frame 2, a transverse rib 3 and a longitudinal rib 4, and the longitudinal rib 4 is radially distributed along the middle of the frame to both sides on the side of the tab.

[0009] In the present invention, in order to have more space for accommodating active materials and increasing the capacitance, the transverse ribs 3 can be designed to face opposite half ribs.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an accumulator grid, which comprises a lug, a frame, transverse bars and longitudinal bars, wherein the longitudinal bars are distributed along the middle part of the frame from the lug side towards the two sides in a way of radioactive rays. In the accumulator grid provided by the invention, based on the principle that the length of the bevel edge is less than that of the sum of two right-angle sides, the longitudinal bars on encryption board grid which are not vertical to the bottom side are intensified to shorten the conduction path of an electric current. The accumulator grid provided by the invention effectively shortens the conduction path of the electric current, which means the defect of long current conduction path in the prior art is overcome. Thus, the accumulator grid effectively reduces the internal drop of an accumulator and prolongs the service life of the accumulator.

Description

technical field [0001] The invention relates to battery grids and belongs to the technical field of electric power storage. Background technique [0002] Currently used as a battery grid, the grid with vertical vertical ribs is generally used. The battery plate made of this structure grid has a long current conduction path, which causes a large internal pressure drop of the battery, resulting in The reduction of output power; when used as a starting battery, the large discharge capacity at the moment of high-power output will cause de-current, so that the current and potential distribution on the grid will be uneven, and the lead paste on the plate will change unevenly and fall off. , not only reduces the holding capacity of the lead paste, but also causes the connection between the positive and negative electrodes, resulting in an increase in self-discharge, which reduces the capacity and the service life of the battery. Contents of the invention [0003] The purpose of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/73H01M4/72

CPCY02E60/10

Inventor 袁朝勇袁朝明

Owner JIANGSU OLITER ENERGY TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com