Empty bottle wall defect detection method and device

A defect detection and bottle wall technology, applied in the direction of optical defect/defect, instrument, calculation, etc., can solve the problems of inability to maintain detection standards, low detection efficiency, unfavorable information integration of manual work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

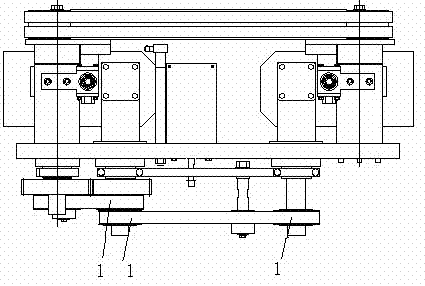

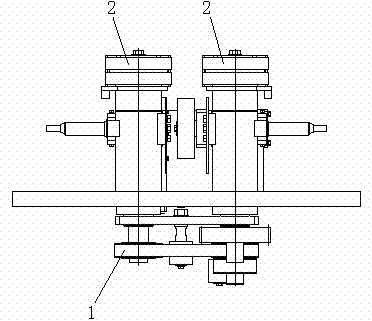

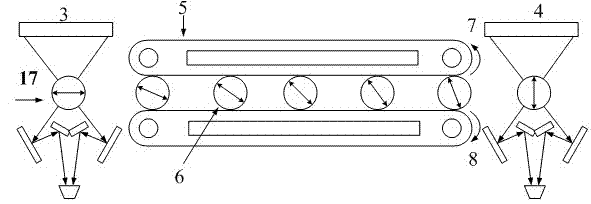

[0067] Such as Figure 1-8 As shown, the hardware structure of the system is composed of a conveyor belt 2, a photoelectric sensor, a CCD camera 12, an image processing system, an industrial computer, a backlight 16 and a supporting strobe controller.

[0068] The working principle of the device is:

[0069] The bottle wall lighting adopts a large-area flat-panel LED backlight 16, which is placed on one side of the bottle wall, and the adjustable color light passes through the bottle wall at a certain angle. The CCD camera 12 is opposite the light source, and the other side of the bottle is collected by a multi-stage combined reflector Image of the bottle wall. The bottle wall inspection consists of the inlet bottle wall inspection unit 3 and the outlet bottle wall inspection unit 4, which are respectively responsible for the image acquisition and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com