Anti-oil well metal equipment corrosion inhibitor, preparation method and using method thereof

A technology for equipment corrosion and corrosion inhibitor, which is applied in the field of corrosion inhibitor for anti-corrosion of metal equipment in oil wells, can solve the problems of restricting the popularization and application of oleic acid bisimidazoline, poor effect and low toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

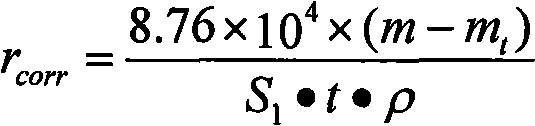

Image

Examples

preparation example Construction

[0025] The preparation method of the corrosion inhibitor provided by the invention comprises the steps of reacting oleic acid and tetraethylenepentamine to obtain bis-imidazoline oleic acid; and uniformly mixing the bis-imidazoline oleic acid with other components of the corrosion inhibitor.

[0026] The preparation process of the bisimidazoline oleic acid includes putting oleic acid into a reaction vessel, adding tetraethylenepentamine under the condition of reflux condensation and stirring, reacting at 100°C-130°C for 2-4h, and then at 180°C- React at 250°C for 3-5h, and finally lower the temperature to 70-100°C to obtain oleic acid bis-imidazoline. The weight ratio of the amount of oleic acid and tetraethylenepentamine is preferably 1-2. Oleic acid can also be added to tetraethylenepentamine.

[0027]Add ethanol and lactic acid into water at 50-80°C, and after they are completely dissolved, add bisimidazoline oleic acid, and mix well to obtain the corrosion inhibitor provi...

Embodiment 1

[0029] Example 1 This example is used to prepare a corrosive medium.

[0030] Weigh 7.35g calcium chloride dihydrate (CaCl2 2H2O), 4.93g sodium chloride (NaCl) and dissolve in about 7L of water, and mix well after completely dissolving; another weigh 1.68g of sodium bicarbonate (NaHCO3) and dissolve in about 1L After completely dissolving in water, mix well; mix the two solutions, dilute to 10.0L with water, and mix well.

Embodiment 2

[0031] Embodiment 2 This embodiment is used for preparing bisimidazoline oleic acid

[0032] Add 113g of oleic acid into a 500ml three-necked flask, slowly add 76g of tetraethylenepentamine dropwise under the condition of reflux condensation and stirring, then turn on the power, heat in an oil bath, and react under the conditions of 110°C and 250 rpm 3h, followed by reaction at 200°C for 5h. Afterwards, the heating was stopped, and the temperature was lowered to 90° C. to obtain bis-imidazoline oleic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com