Technology for refining lead from lead chloride slag by means of pyrometallurgy

A lead chloride and process technology, which is applied in the field of extraction of metallic lead and lead chloride slag pyro-smelting process, can solve the problems of unsuccessful implementation and unreachable lead direct yield, and achieves good equipment sealing performance and separation. Simple and economical method, low heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

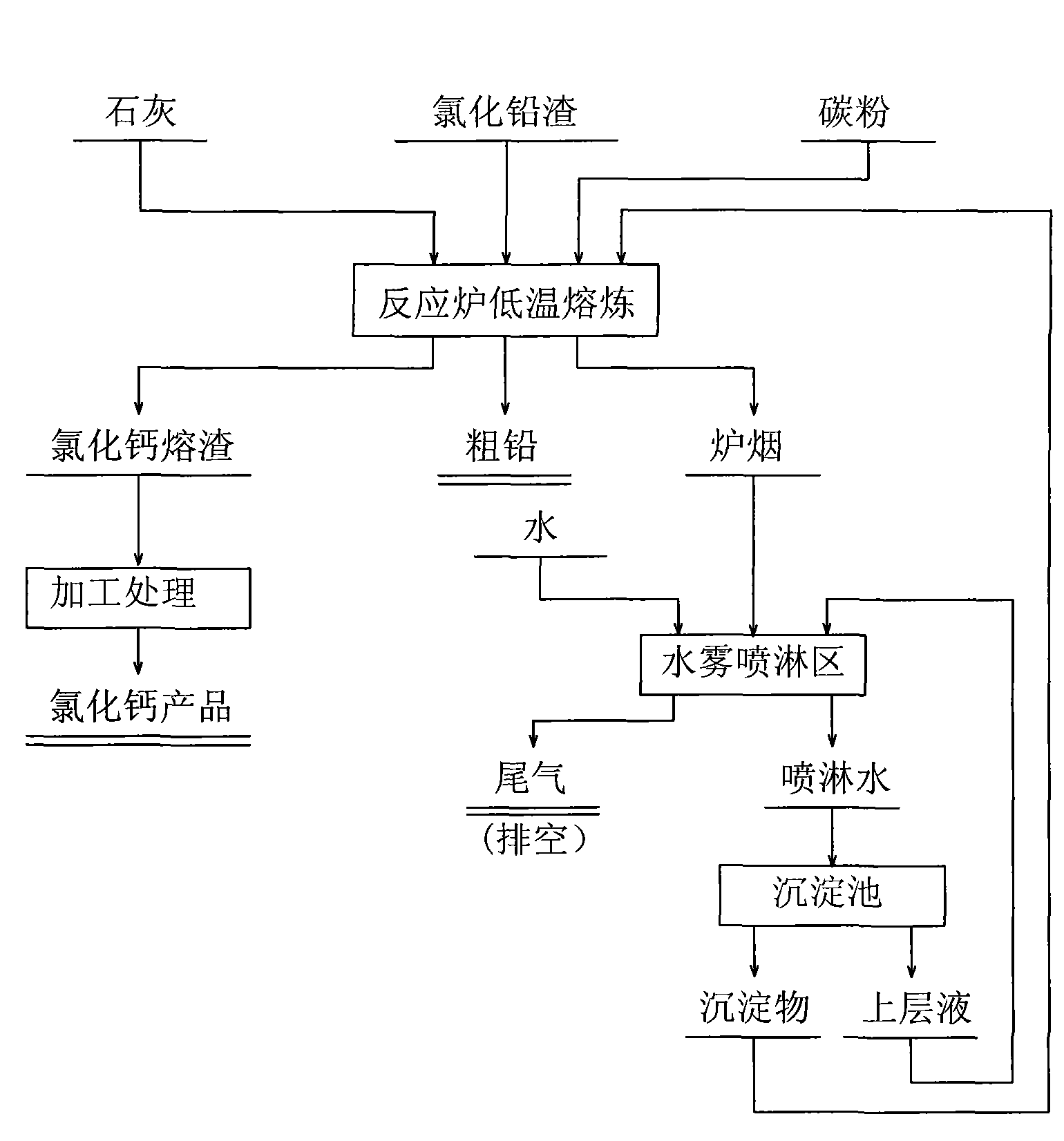

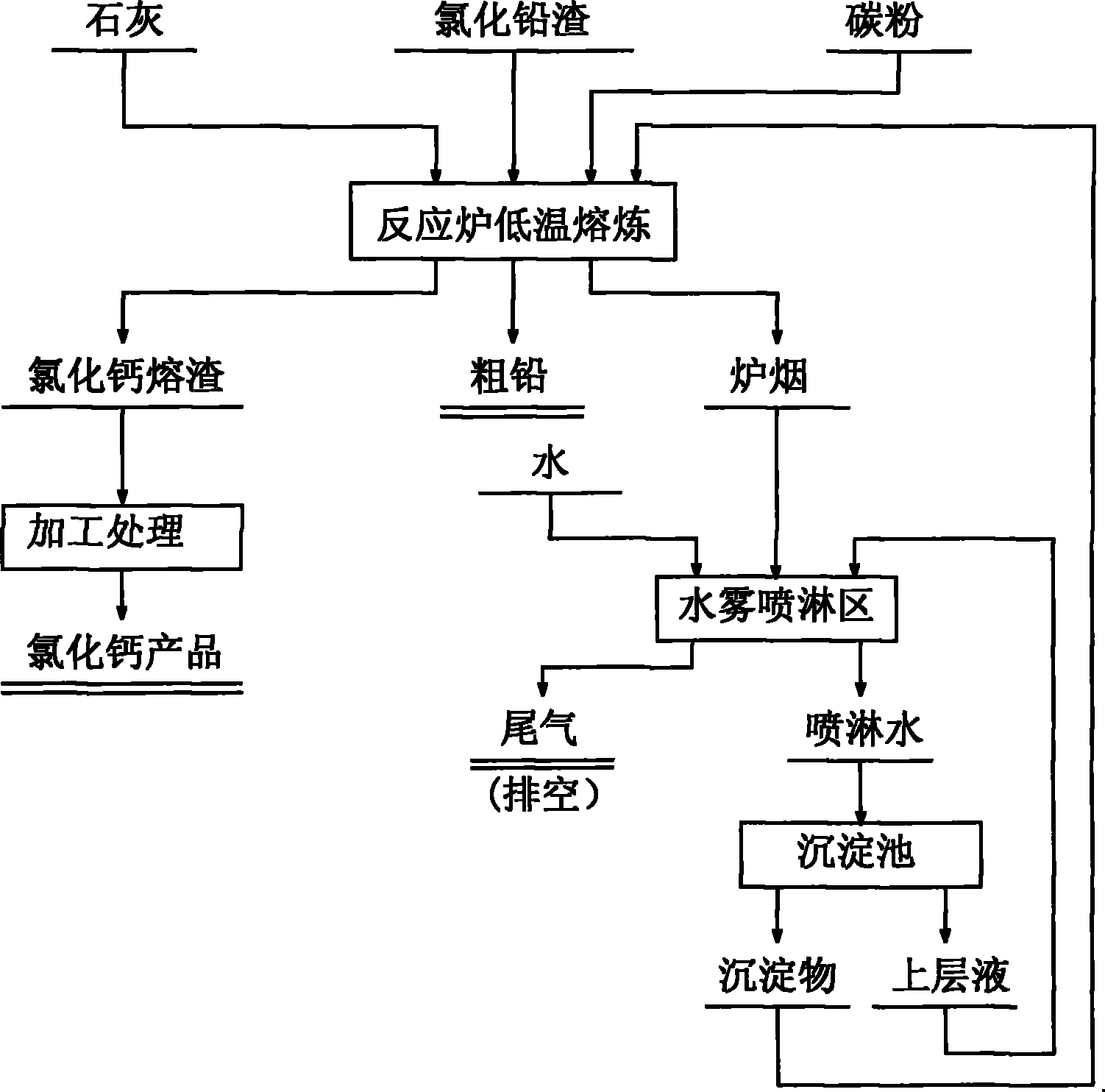

[0016] Reference attached figure 1 A kind of lead chloride slag fire method lead smelting process, its concrete process is:

[0017] (1) First, mix 1t of lead chloride slag with 0.3t of lime and 0.06t of carbon powder into the reaction furnace consisting of a combustion chamber, a high-temperature zone, a low-temperature zone, and a flue; add coal from the combustion chamber of the reaction furnace to burn Heating, low-temperature smelting in the low-temperature zone of the reaction furnace; the smelting temperature is 400°C, and the smelting time is 30 minutes; lead chloride slag and lime are melted and reacted in the low-temperature zone to generate lead hydroxide melt and calcium chloride slag; the reaction formula yes:

[0018] PbCl 2 +2CaOH→Pb(OH) 2 +2CaCl 2

[0019] (2) Lead hydroxide melt and calcium chloride slag flow to the high temperature zone of the reaction furnace immediately, and the furnace temperature in the high temperature zone is controlled at 800°C; u...

Embodiment 2

[0030] Reference attached figure 1 A kind of lead chloride slag fire method lead smelting process, its concrete process is:

[0031] (1) First, mix 1t of lead chloride slag with 0.32t of lime and 0.07t of carbon powder into the reaction furnace consisting of a combustion chamber, a high-temperature zone, a low-temperature zone, and a flue; add coal from the combustion chamber of the reactor furnace to burn Heating, low-temperature smelting in the low-temperature zone of the reaction furnace; the smelting temperature is 450°C, and the smelting time is 25 minutes; lead chloride slag and lime are melted and reacted in the low-temperature zone to generate lead hydroxide melt and calcium chloride slag; the reaction formula yes:

[0032] PbCl 2 +2CaOH→Pb(OH) 2 +2CaCl 2

[0033] (2) Lead hydroxide melt and calcium chloride slag flow to the high temperature zone of the reaction furnace immediately, and the furnace temperature in the high temperature zone is controlled at 750°C; u...

Embodiment 3

[0044] Reference attached figure 1 A kind of lead chloride slag fire method lead smelting process, its concrete process is:

[0045] (1) First, mix 2t of lead chloride slag with 0.59t of lime and 0.13t of carbon powder into the reaction furnace composed of combustion chamber, high temperature zone, low temperature zone and flue; add coal from the combustion chamber of the reaction furnace to burn Heating, low-temperature smelting in the low-temperature zone of the reaction furnace; the smelting temperature is 500°C, and the smelting time is 40 minutes; lead chloride slag and lime are melted and reacted in the low-temperature zone to generate lead hydroxide melt and calcium chloride slag; the reaction formula yes:

[0046] PbCl 2 +2CaOH→Pb(OH) 2 +2CaCl 2

[0047] (2) Lead hydroxide melt and calcium chloride slag flow to the high temperature zone of the reaction furnace immediately, and the furnace temperature in the high temperature zone is controlled at 770°C; under this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com