Method for preparing graphene oxide with high fluorescent quantum yield

A fluorescent quantum yield and graphene technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as limited application, weak photoluminescence, and observation, and achieve the effects of easy promotion, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Heat 25ml of concentrated sulfuric acid to 90°C, add 1g of K 2 S 2 o 8 and 1g P 2 o 5 , 1.2g of graphite flakes were reacted for 4.5h, and the reacted product was diluted with 200ml of deionized water, filtered, washed, and then dried in a vacuum oven. Take 0.1g of dried pretreated graphite and add 23ml of concentrated sulfuric acid and 1g of KMnO 4 React at 35°C for 2h, then add 46ml of water and react at 95°C for 0.5h, and finally add 3ml of H 2 o 2 The reaction was terminated, the obtained product was centrifuged, and washed five times with deionized water and 10% HCl solution, and the finally obtained solid was put into a vacuum oven for drying;

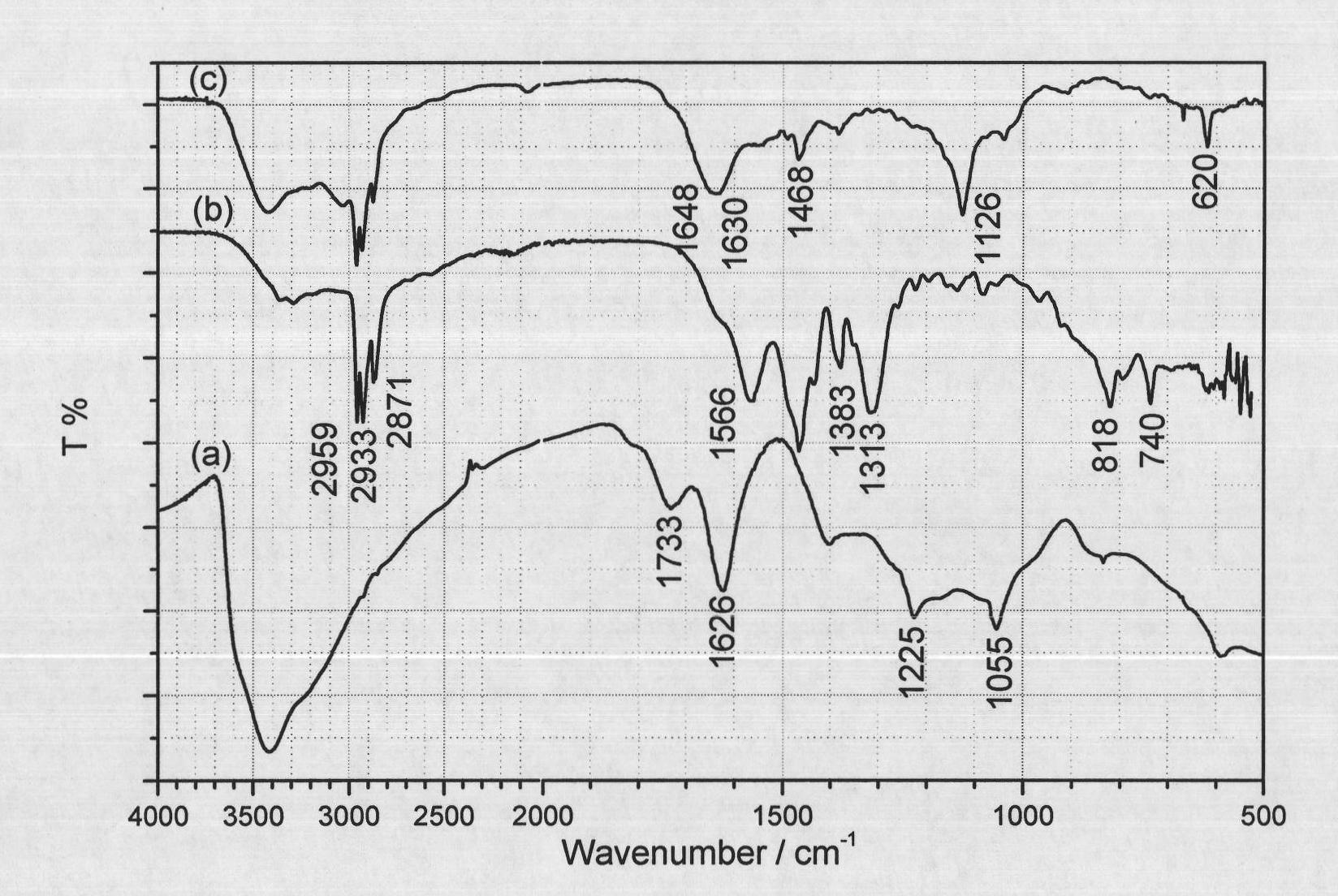

[0028] (2) Take 20 mg of dried graphite oxide, add 1 ml of anhydrous DMF, and obtain graphene oxide by ultrasonication for 30 minutes, then add 20 ml of thionyl chloride, and reflux at 80 ° C for 24 hours under nitrogen protection. Then centrifuge to remove unreacted thionyl chloride, wash twice with anhydrous t...

Embodiment 2

[0032] (1) Heat 25ml of concentrated sulfuric acid to 90°C, add 1g of K 2 S 2 o 8 and 1g P 2 o 5 , 1.2g of graphite flakes were reacted for 4.5h, and the reacted product was diluted with 200ml of deionized water, filtered, washed, and then dried in a vacuum oven. Take 0.1g of dried pretreated graphite and add 23ml of concentrated sulfuric acid and 1g of KMnO 4 React at 35°C for 2h, then add 46ml of water and react at 95°C for 0.5h, and finally add 3ml of H 2 o 2 The reaction was terminated, the obtained product was centrifuged, and washed five times with deionized water and 10% HCl solution, and the finally obtained solid was put into a vacuum oven for drying;

[0033](2) Take 20 mg of dried graphite oxide, add 1 ml of anhydrous DMF, and obtain graphene oxide by ultrasonication for 30 minutes, then add 20 ml of thionyl chloride, and reflux at 80 ° C for 24 hours under nitrogen protection. Then centrifuge to remove unreacted thionyl chloride, wash twice with anhydrous te...

PUM

| Property | Measurement | Unit |

|---|---|---|

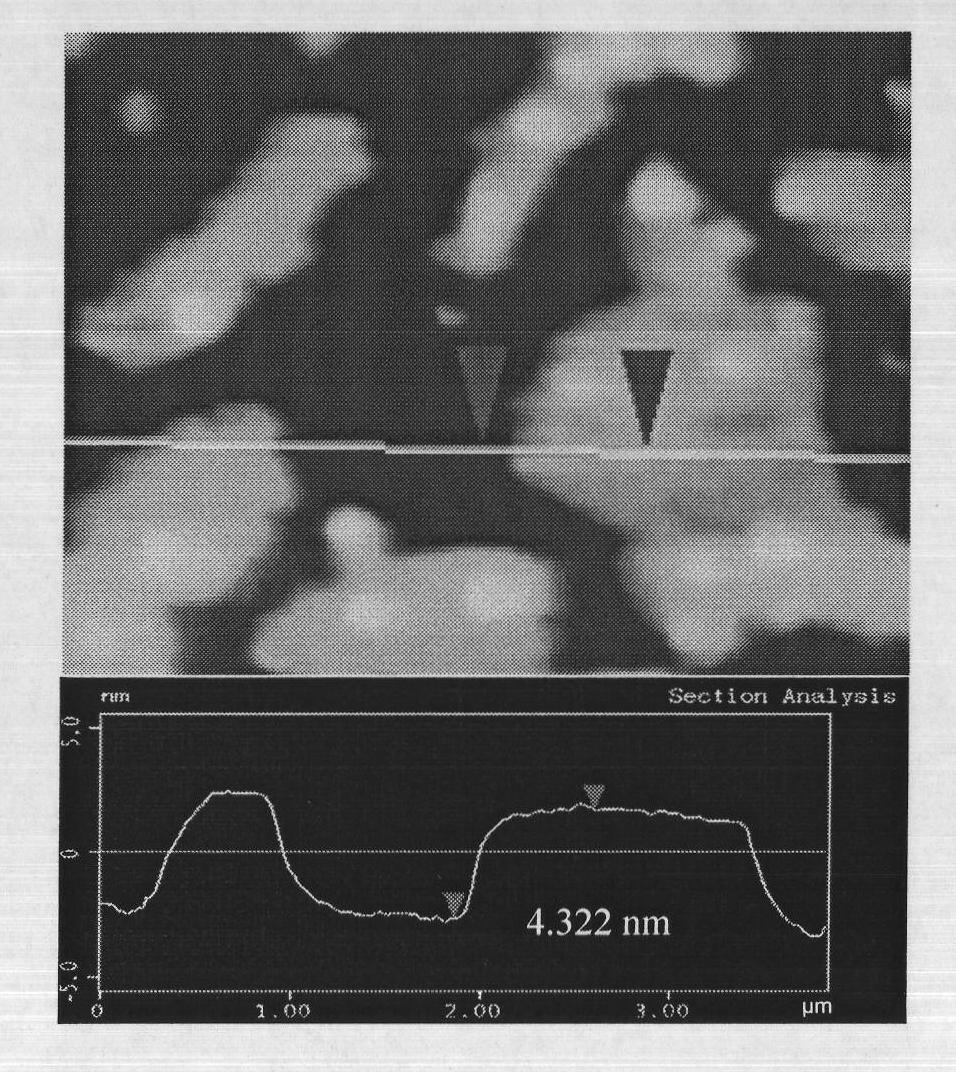

| thickness | aaaaa | aaaaa |

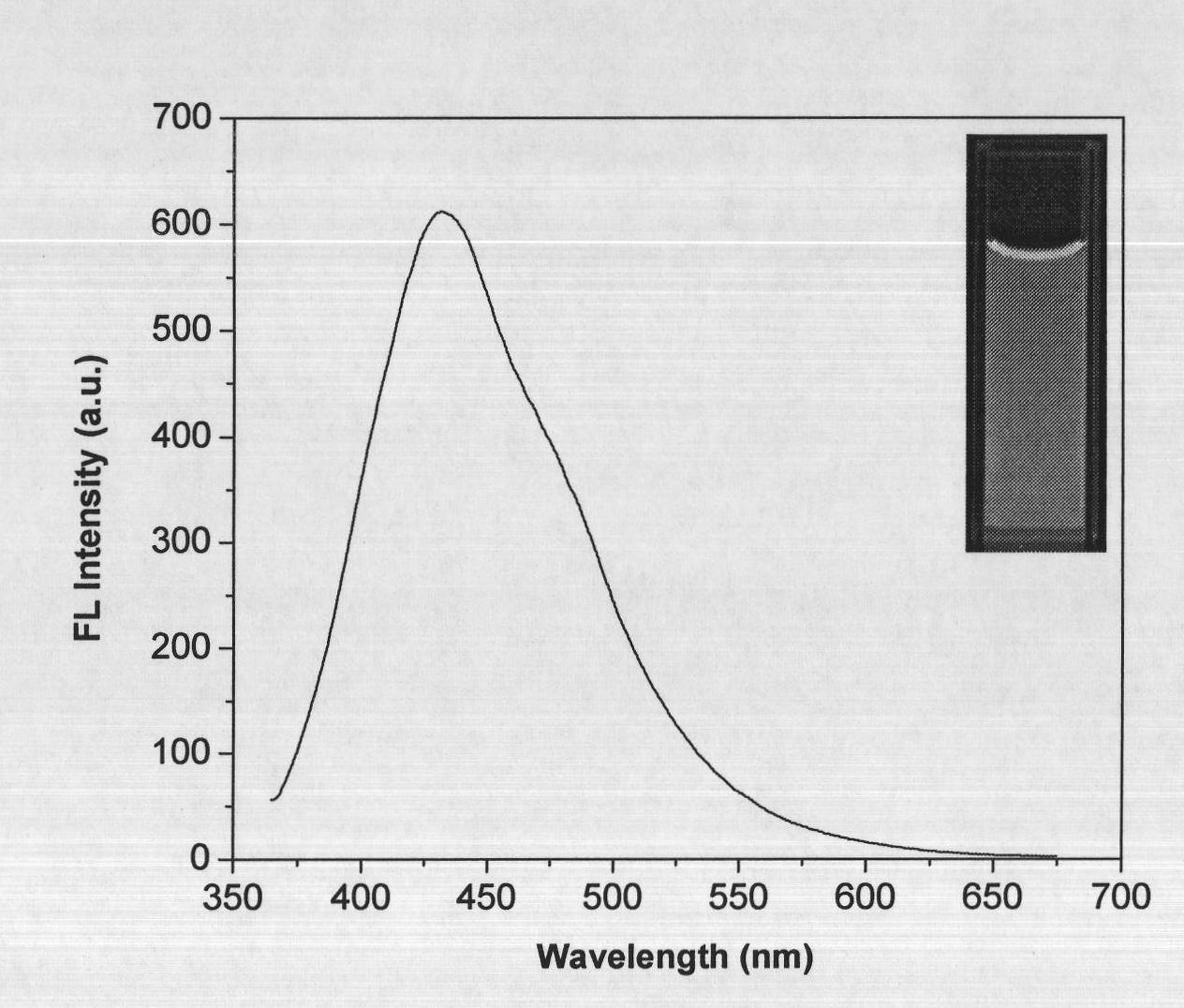

| fluorescence quantum yield | aaaaa | aaaaa |

| fluorescence quantum yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com