Antibacterial and bacteriostatic UV offset printing ink

A technology of offset printing ink and volatile oil, applied in the field of printing ink, can solve the problems of destroying ink, ink film, contaminating printed matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

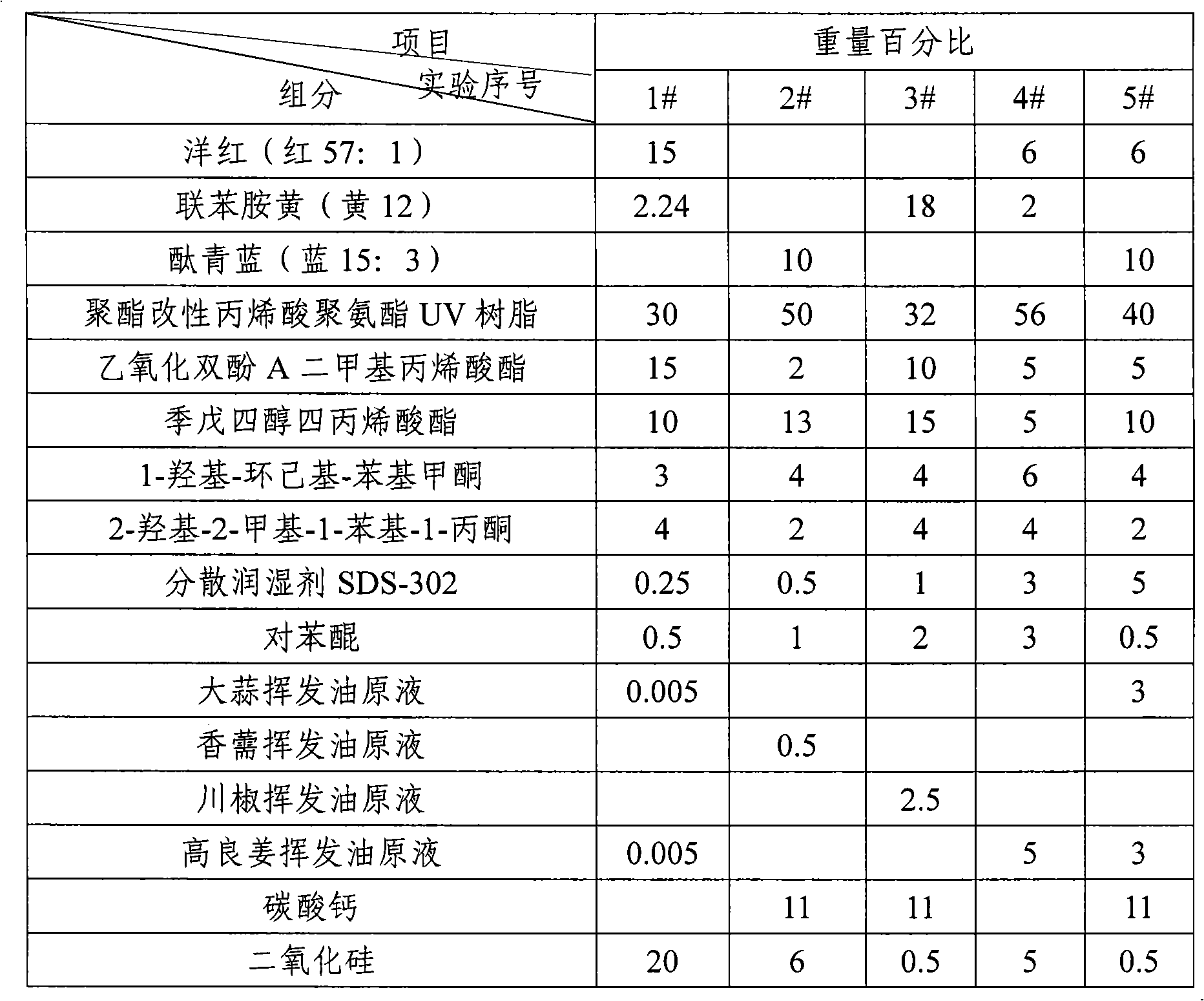

[0035] 1. Raw material preparation: batching with the weight percentage of each component shown in table 1:

[0036] Table 1

[0037]

[0038] Among them, the polyester-modified acrylic polyurethane UV resin is self-made, and the specific preparation process includes: 1) adding measured amounts of adipic acid, trimethylolpropane and diethylene glycol into a four-necked flask, and starting to heat up. During the heating process, the water will gradually come out, and stir until the powder is completely melted. When the temperature rises to about 160°C (about 2 hours), add antioxidant, blow nitrogen, and add reflux xylene from the upper part of the condenser tube. Gradually raise the temperature to 190-195°C, keep it warm for 6-8 hours, then stop heating and turn off the nitrogen. Start vacuuming, and discharge after 1 hour to obtain hydroxyl-terminated polyester (PE). 2) Add toluene diisocyanate into a four-necked flask, adjust the pH value to 4-5 with a small amount of c...

Embodiment 2

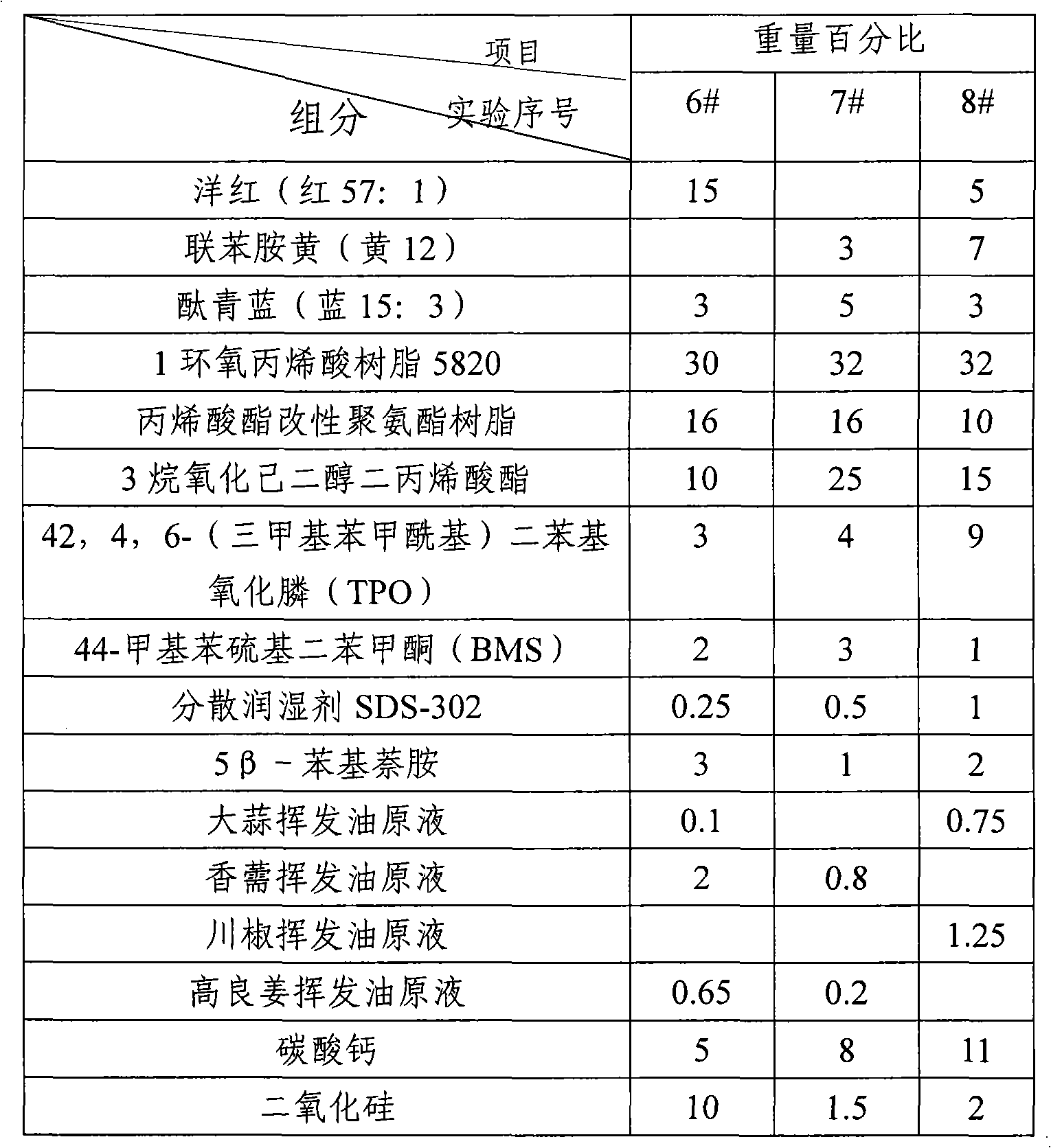

[0046] With the weight percent batching of each component shown in table 2:

[0047] Table 2

[0048]

[0049] Among them, the acrylate-modified polyurethane resin is self-made, and the specific preparation process includes: weighing a certain amount of polycarbonate hexylene glycol ester, putting it into a four-necked bottle, and vacuum dehydrating. Then, add a certain amount of dihydroxypropionic acid, acetone, DBT, etc., drop toluene diisocyanate, control the reaction temperature not higher than 80 degrees, react for 3 hours, cool down, add a certain amount of HEA, and react at 70-75 degrees 1.5 hours; cool down to 40 degrees, add quantitative methyl methacrylate and triethanolamine, stir for half an hour; disperse the reaction mixture in water; add the initiator to the above dispersion, and free radical polymerization at about 80 degrees for 3.5 hours , Put this liquid into a distiller, distill off the acetone to obtain acrylate-modified polyurethane.

[0050] 2. Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com