Frequency conversion system of rotor of alternating current mine hoist

A mine hoist, frequency conversion system technology, applied in the direction of AC motor control, lifting equipment in mines, control systems, etc., can solve the problems of many hidden trouble points, waste of energy, power consumption, etc., to achieve stable operation, safety and reliability, Improved safety and reliability, fewer hidden trouble points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiment of the present invention is described in conjunction with accompanying drawing:

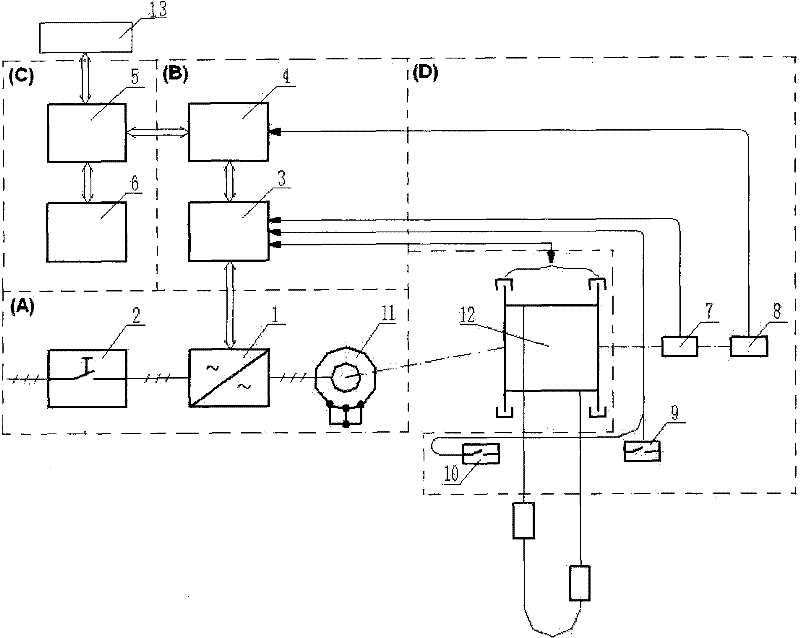

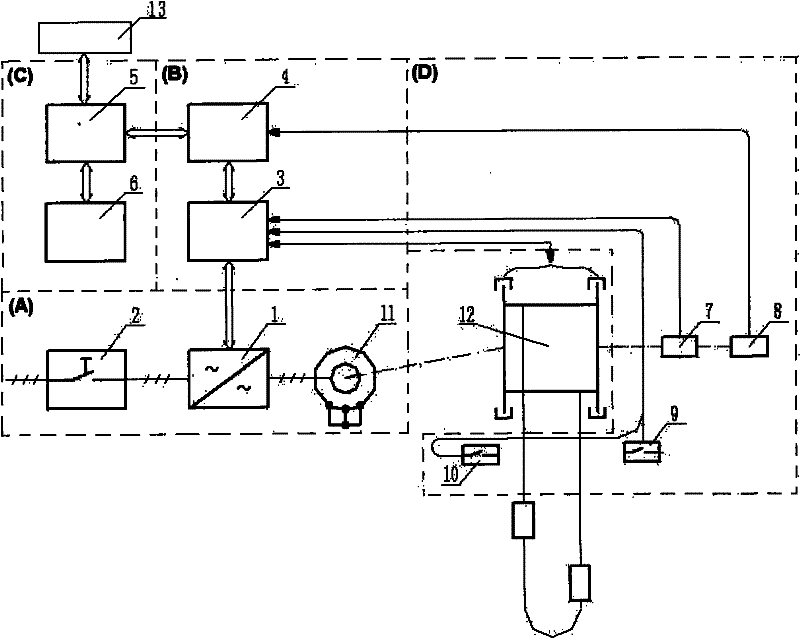

[0011] exist figure 1 Among them, the AC mine hoist rotor frequency conversion system proposed by the present invention is mainly composed of a rotor frequency conversion speed regulation part A, a process control part B, a process monitoring part C, and a depth speed detection part D; the rotor frequency conversion speed regulation part is composed of a switch cabinet 2, The rotor frequency modulation and voltage regulation device 1 is composed of a motor 11. The output end of the rotor frequency modulation and voltage regulation device 1 (refer to the invention patent application number: 200810141371.6) is connected to the rotor winding of the motor 11, and the stator winding of the motor 11 is short-circuited at its output terminal. The input terminal of the rotor frequency modulation and voltage regulating device 1 is connected to the output terminal of the switch cabinet 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com