Method for manufacturing magnetic loading type nanometer catalyst TiO2/Fe2O4

A nano-photocatalyst and a production method technology are applied in the field of production of magnetically supported nano-photocatalyst TiO2/Fe3O4, which can solve the problems of incapability of industrial application, difficult recycling, high cost of wastewater treatment, and achieve good photocatalytic activity and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The magnetic loaded nano photocatalyst TiO 2 / Fe 3 o 4 The production method is characterized in that it comprises the following steps:

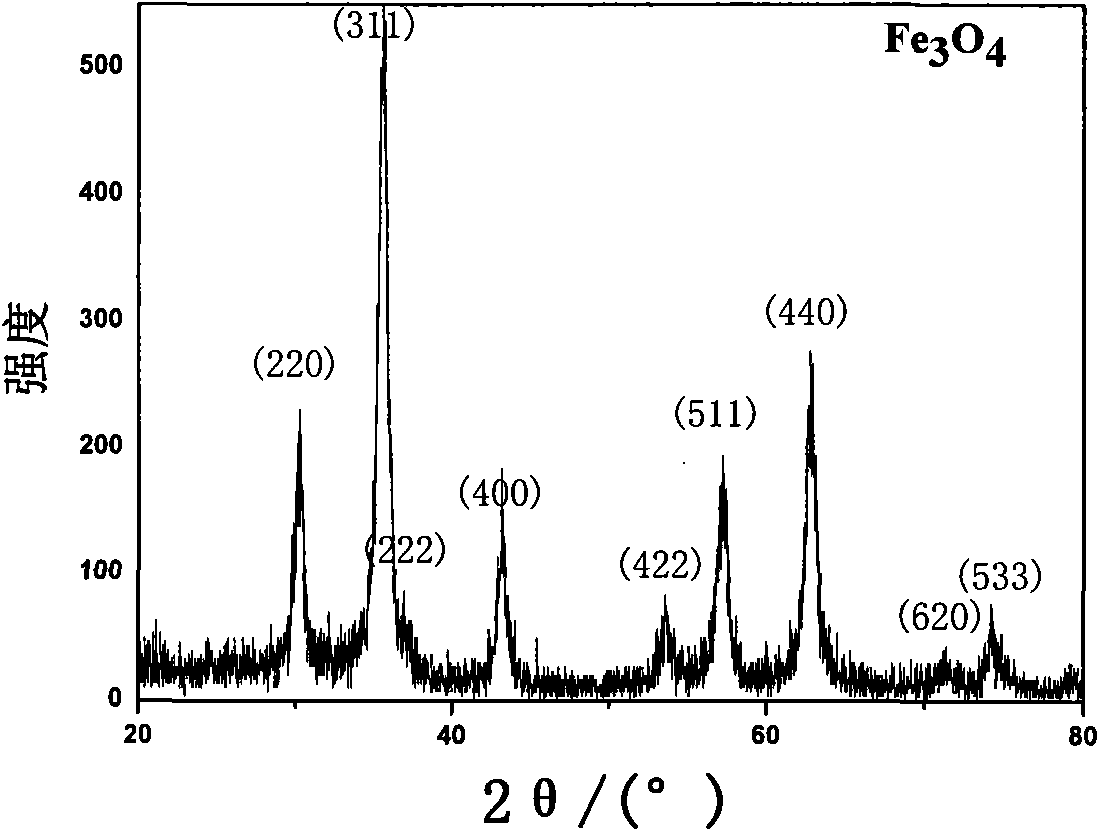

[0015] 1) Using the co-precipitation method, using ferrous sulfate, ferric sulfate, and ammonia water as the main raw materials, to prepare black nano-Fe with good dispersibility 3 o 4 particles, the reaction conditions are: reaction temperature 60°C, Fe 3+ : Fe 2+ The molar ratio is 1.8, the reaction time is 70min, the crystallization temperature is 60°C, the pH of the reaction solution is 11, and the amount of surfactant is 10% of the iron ion content;

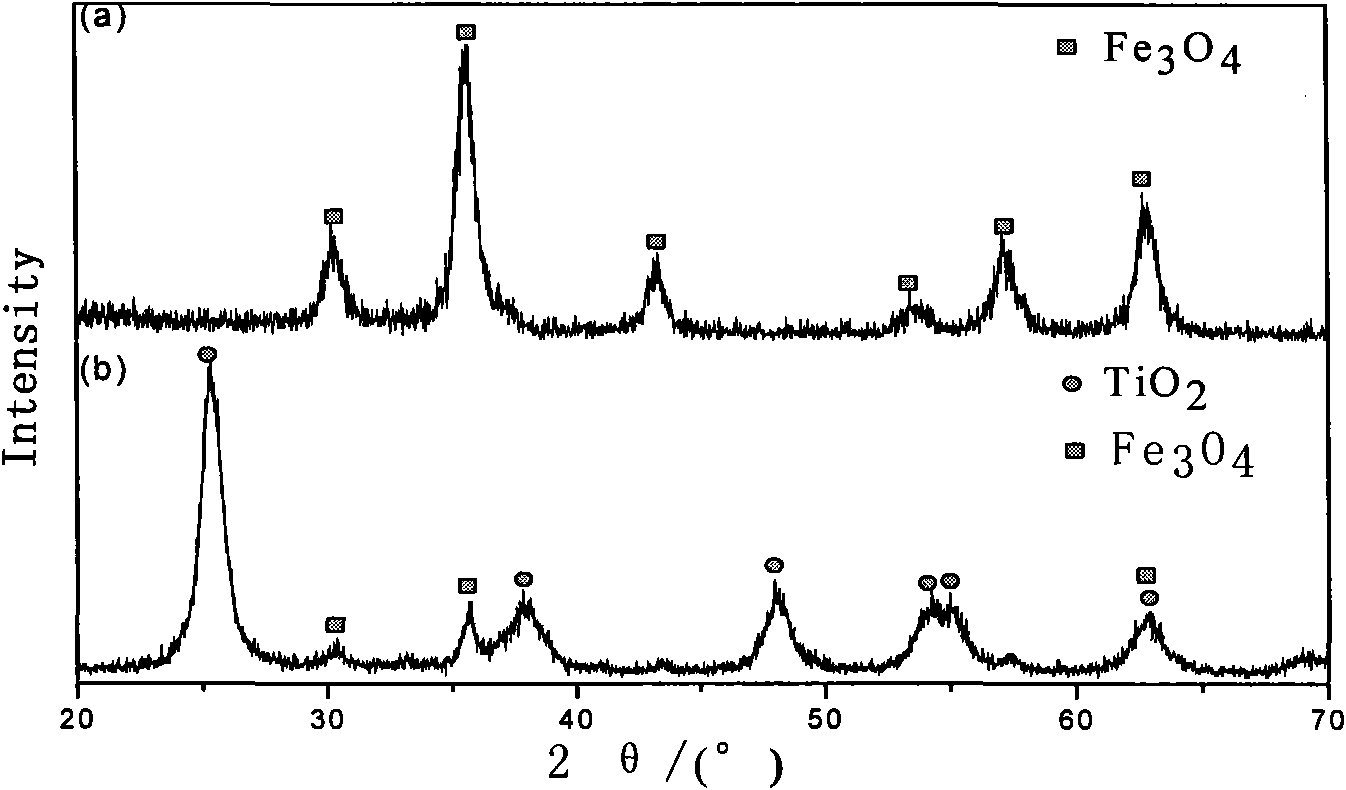

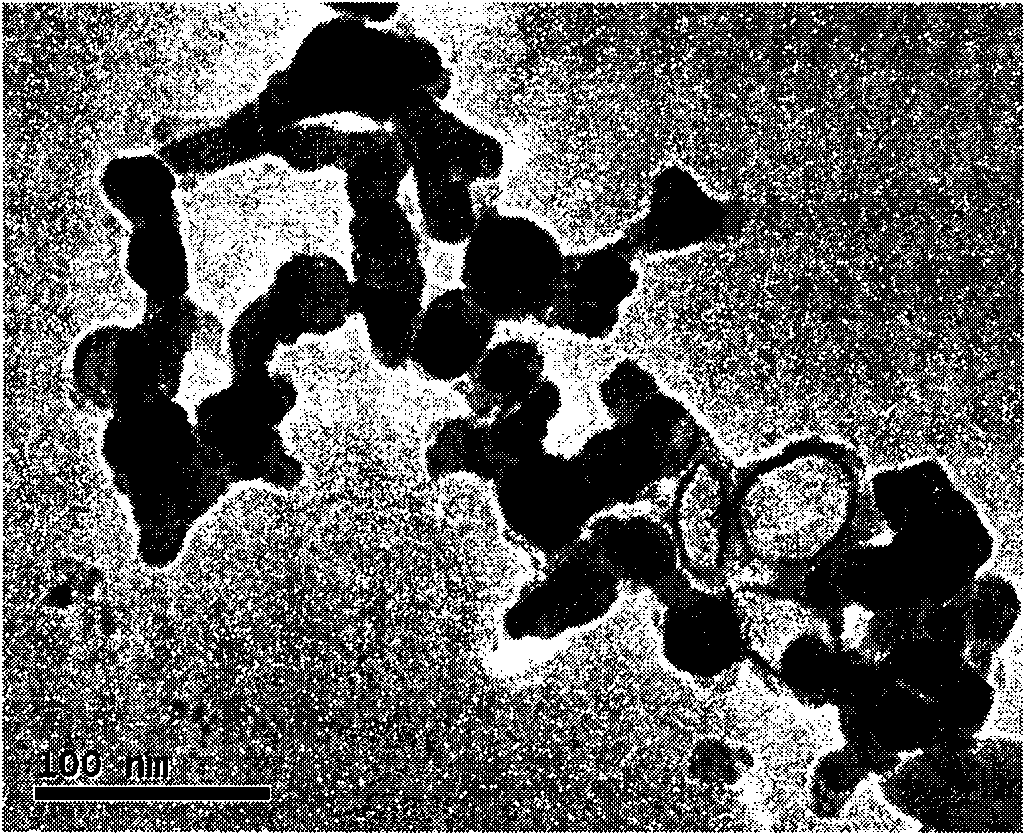

[0016] 2) by sol-gel method in Fe 3 o 4 The surface is coated with a layer of photocatalytic TiO 2 , forming a core-shell structure of TiO 2 / Fe 3 o 4 Composite material, the particle size of the composite material is about 30nm, has superparamagnetism, and the TiO on the surface 2 The layer has an anatase structure, and the reaction conditions for preparing nano-titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com