Double 12-pulse valve bank coordinated-control method for ultra-high voltage direct-current transmission system

A UHV DC, coordinated control technology, applied in the direction of parallel operation of DC power supplies, can solve problems such as unbalanced voltage distribution, trigger angle deviation, etc., and achieve the effect of solving competitive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

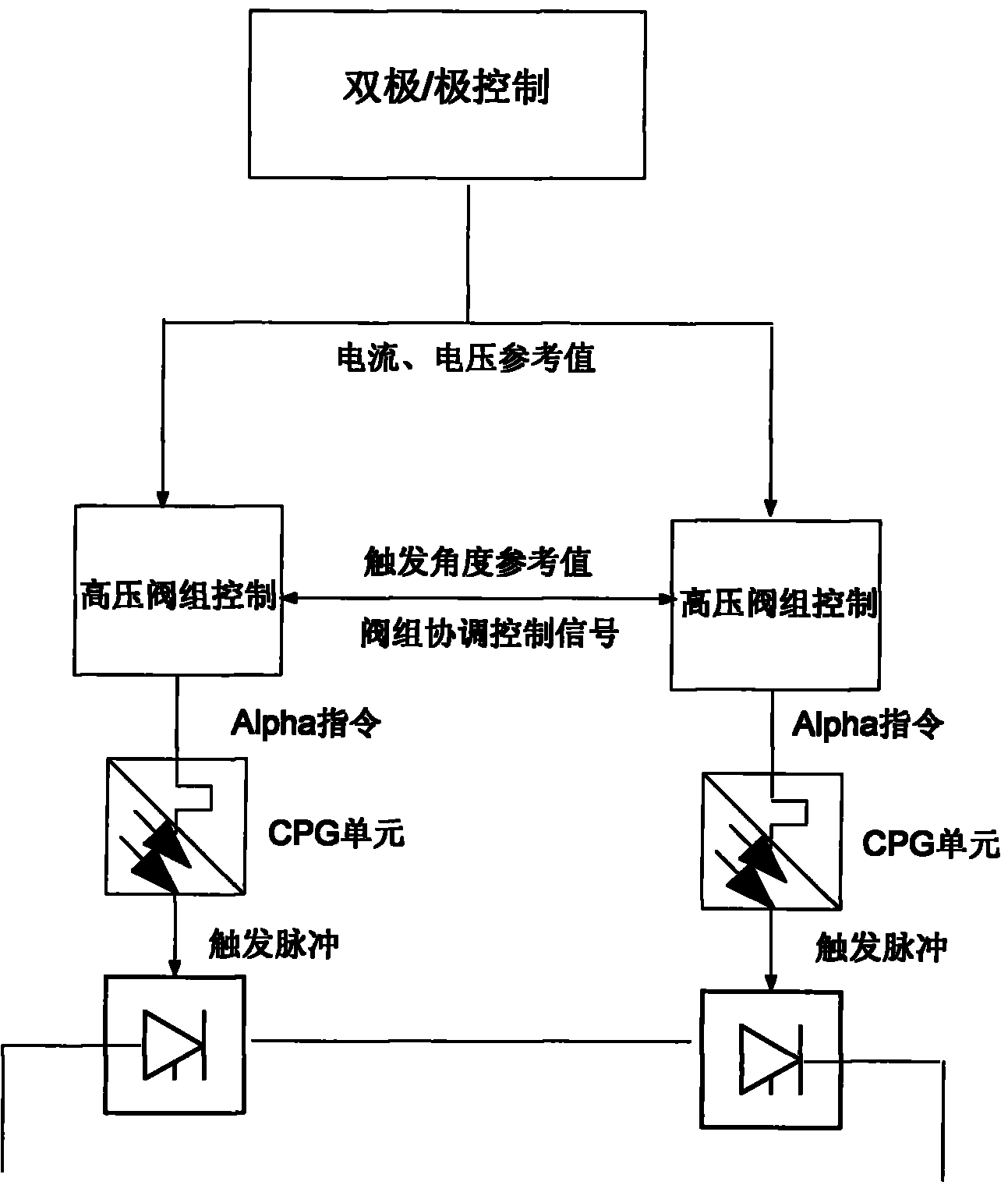

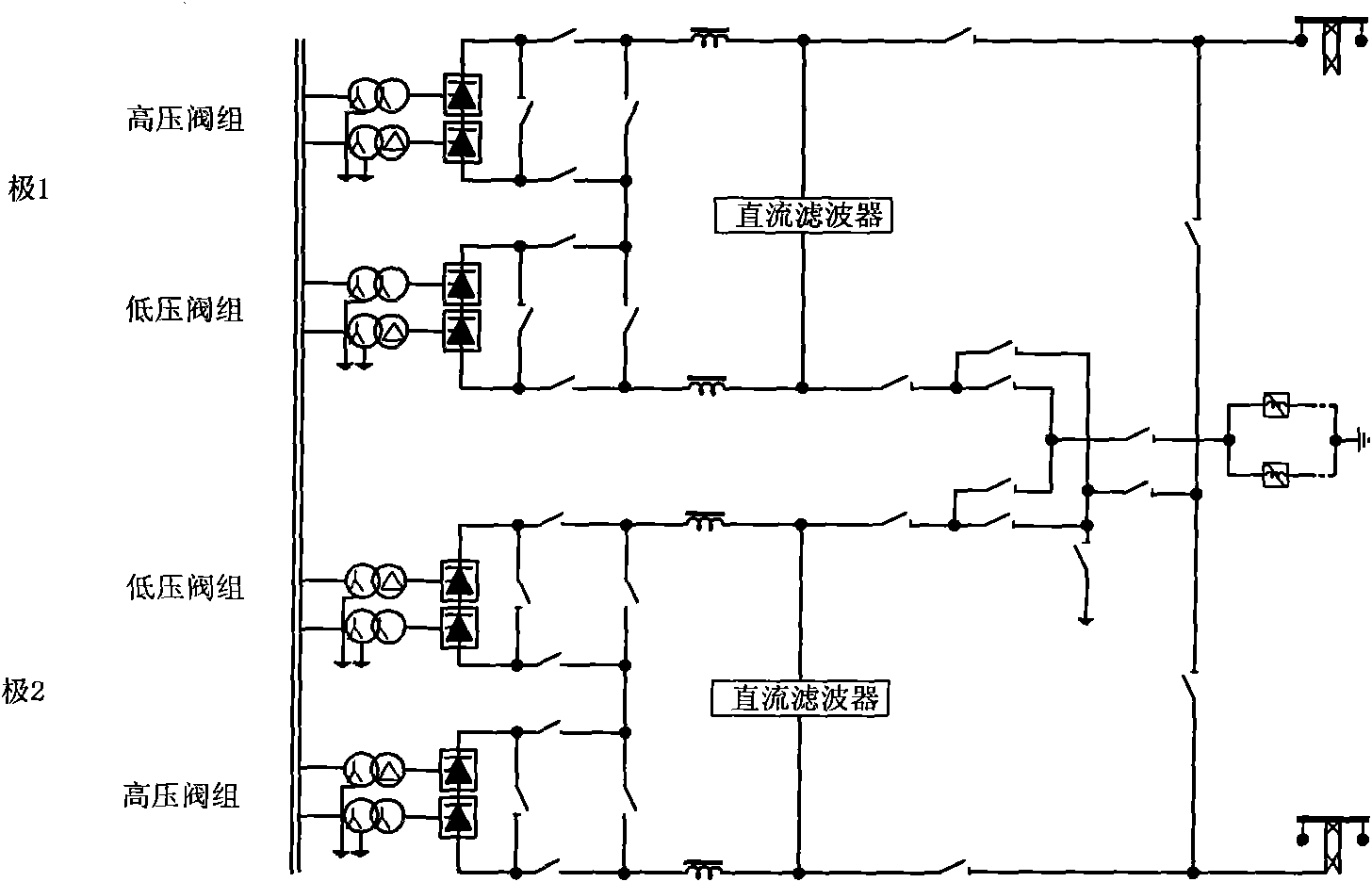

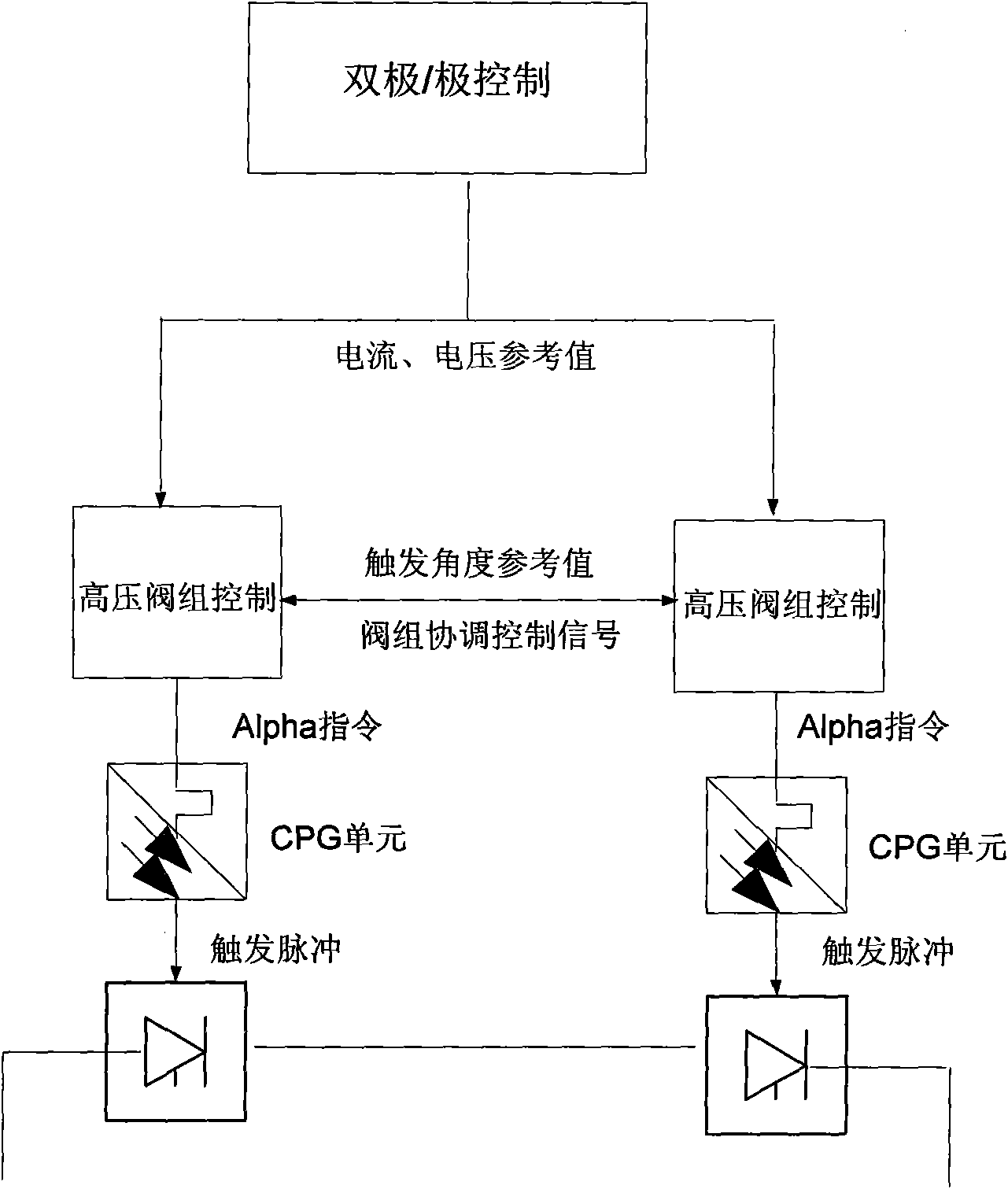

[0018] The present invention will be further described according to the accompanying drawings: In order to realize the coordinated control of each 12-pulse valve group connected in series, a physically independent converter valve control unit is adopted, and the bipolar / polar control layer and the valve group control layer adopt mutual independent device implementation.

[0019] A main computer completes the functions of the bipolar / pole control layer, mainly realizing the calculation and distribution of power / current commands, the coordination of current commands between stations, the switching control of reactive power equipment in stations, and the DC sequence control of stations and poles.

[0020] As shown in Figure 2, bipolar / polar control sends the calculated current and voltage commands to the valve group control host computer at the next level. The valve group control main computer is used for valve group trigger control. The main control functions are: valve group t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com